Doug Coffey’s RetroMod Panhead Part 2

By Robin Technologies |

Bikernet/Cycle Source Sweeps Build Part 7 Sponsored by Xpress

By Robin Technologies |

Hang on. We are two weeks away from running out to Vegas for Bikefest and pulling the winner of this most magnificent custom motorcycle, specifically built for Bikernet and Cycle Source fans, readers, and subscribers. You need to sign up, if you haven’t, or come to the Cashman Center in Vegas to grab a card and sign up for the drawing. You don’t need to be on site to win. After Bikefest, the scooter will return to Kustoms Inc. near Detroit, for final tuning and break-in before being shipped to the winner.

So here’s the update in a flash, after Bonneville, and heading smack dab against a Cycle Source Deadline. “I’m way behind,” said Chris Callen, the esteemed Editor da Emperor, in Chief, in Charge, in Trouble. This year has turned into the scrambling year. We are scrambling to finish projects; builders are scrambling to finish bikes. Chris scrambles every month to finish a magazine. It’s bananas.

The bike was displayed in Sturgis at the Broken Spoke. Then it returned to Grand Ledge, Michigan, down the street from Ron Finch, for final manufacturing and paint by the master of Chop Docs, Ron Harris, but let’s finish the pieces first.

“I kill batteries no matter what I do,” Gary Maurer said as we started to discuss the battery box. “When I carefully rubber-mount the bastards, they vibrated enough to rip the battery cables to shreds.” So now he puts a small rubber lining under the battery and bolts the unit down hard with Jules-made steel battery straps. He is now using Brail and Ballistic batteries with some luck. This is where I started to learn more manufacturing processes from Gary and Jules, again.

It’s interesting. I don’t consider myself a builder, and when I work with someone with the manufacturing knowledge of the Kustoms Inc. team, I know I’m just an enthusiast, not anywhere near a pro builder. This story contains a couple of fine examples of their expertise. The battery straps are easily bent after marking the position for the bend on the top corner edge of the battery. Jules made the hand bend with a solid bar of steel, and then noted the amount of metal used in the radius and worked it into the formula for the next bend so the strap fit the battery perfectly.

“There is a mathematical formula for this process,” Gary said. “You need to add or subtract material from the next bend, but we bend one side and then adjust the other.”

I also noted how perfectly the fender edge fit the line of the tire, since most fenders do not align with the tire radius. “We often scribe the radius of the tire on the fender and cut it to match perfectly,” Gary said.

He uses thick welder ground cable stock taped to the fender to give him the proper fender clearance. “Sometimes we use chunks of busted rear drive belts,” Gary said. “Sometimes, if need be, we can double the belt, or mesh the teeth for a slightly larger space.”

They break the chain to be as close to the center of the adjustment path as possible, with the engine, primary and transmission in place. Then they adjust the chain to be bowstring tight, and then they tape the spacing material to the tire and start mounting the fender.

This Bare Knuckles fender was bobbed and channeled on both sides by Jules. She often cuts with a plasma cutter, and then works the edge with Matabo grinder with flap wheels. Bare Knuckle fenders are made with solid, thick spun steel. They are as strong as a battleship hull and easy to work with. “Our plasma was toast,” Gary said, “so she used a high-speed cut-off wheel, then the Matabo and flap wheels.

I like the exhaust system he built with D&D components and a carbon fiber muffler. I asked how he held the components accurately together for tacking. “I start generally, but not always, with the muffler in place and move forward,” Gary said. “I hold the chunks in place with three fingers and tack them.” If his weld pulls away from the joint, he adds a small ball of rod to one piece, then holds them together, and heats the ball until it flows to the other tubing piece.

Note how Jules fashioned the lower fender mount to the frame so it acted as a battery strap mount and fender mount.

Then Gary built the sissy bar by hand-bending the steel rod. He machined each chunk of bar stock for the frame rails, and drilled them ½-inch so the rail would simply insert into the welded boss. Then he drilled and tapped them for setscrews. On the top, he welded a machined bung to the bar, and a drilled and tapped the bung to the fender, so the fastener simply slips through the sissy bar tab and screws into the solid bung on the fender.

With all the components tested and brushed with flapper wheels, Ron Finch stopped by and picked up the components for the trip to Ron Harris, a third generation paint and body shop guy. “I couldn’t touch a paint gun until I could bump a fender,” Ron said of his granddad. Back in the day, bodywork was hammered and filled with brazing and lead.

“My dad called Bondo Chinese lead,” Ron said. Then he ran down the Chop Docs custom paint process. From the photos, paintwork slides along like ironing an old pair of Levis (who the hell does that anymore?), but any top-notch painter has the talents of a concert violinist. It may look easy, but there’s a refined eye and level of perfection that turns any steel surface into a perfectly smooth piece of art.

As soon as Ron Finch dropped off the components and peeled out, Ron Harris cleaned the welds with a cookie wheel, and then scuffed all the surfaces with 80-grit for a world-class bonded protective coating. Initially, paint was used solely to protect a surface. Now it protects and adds the final illustrious finish.

Then he coated all the sheet metal surfaces with a filler Bondo skin coat and block-sanded the surfaces. This is where perfection and talent come into play. I’ve been there. I couldn’t Bondo a baby moon hubcap and make it look like new. There’s an eye for sanding just the right level of Bondo to capture the perfect slick surface.

He followed the Bondo coating with a skim coat of putty to capture imperfections, and then tested his eyes with various levels of Emory paper from 80-grit, to 150, to 320, so he can minimize his primer usage.

“I’ve been working with Stage 5 Coatings for two years,” Ron said.

Stage 5 Coatings was established in 2008 and is the newest and one of the fastest growing coatings suppliers in the United States. We are committed to selling jobber direct and establishing an exclusive territory for anyone that carries our lines. We strive to offer the best values available in the market. We are a small company that is personal and ethical. We build a personal working relationship with every customer, whether they are our largest or smallest. We believe when a customer buys from us, a partnership is formed, and is not just another customer. We have the industry experience to put ourselves in your shoes and understand the everyday struggles in the body shop business. From us to the jobber to manufacturing, we have the personal hands-on experience in all areas of the aftermarket coatings industry.

States with Stage 5 or Technico:

Michigan New York

Illinois Missouri

Texas Oklahoma

Wisconsin Oregon

California Arizona

Washington Georgia

Maryland Caribbean

Virginia

Ron is working with Ken Dudley on a line of Chop Docs candies. After he primed all the surfaces, he used a black spray bomb dusting to cause imperfections to surface. After any pits or surface maladies were dealt with, he water-sanded everything with 400 grit wet and dry, and then hand-sanded with 600 grit and finished off with Scotchbrite.

With the components hung in a booth, he primed them with two coats of sealer, and then hit them with the silver base coat and inner clear before taping off for the black pearl inlay. Then everything was cleared again and sanded with 600-grit.

This was Ron’s first attempt with green variegated leaf* using Mona Lisa glue to attach it to the paint surface. “It’s like a very thin, watered-down Elmer’s glue,” Ron said. “The leaf is so thin, it’s like dust in your hands.”

Once the leaf was glued into place and the area cleaned with a cotton ball or a brush, Ron hit it with another coat of inner clear, which locks the base down and leaves sort of a satin surface to adhere any art to, such as pin striping by John Harrow, who used a one-shot enamel sign paint called Kansas City Teal.

Now for the final six layers of gloss clear coats and 1500 grit wet sanding, followed by 3000 grit with water, and then buffing with polishing compound, finishing glaze, and spit shine. It’s Saturday, and by Monday, all the elements will be returned to Gary and Jules and Kustoms Inc. for final assembly. Ron volunteered to help. Unfortunately, he’s 140 miles away, but he drove out and spent all day, Sunday, helping with assembly. “It’s 80 percent there,” Ron said on his way home.

Speaking of volunteer efforts, this has been an amazing build with efforts from a variety of sources, all to create a bike we are giving away. No one made a dime off this puppy. It’s all American-made, and the whole gang pulled together to offer Bikernet and Cycle Source readers a shot at a world-class custom motorcycle—thanks. Chance of a lifetime, goddammit.

Dimensions: 5½” x 5½”

Xpress

http://mysmartcup.com/

Crazy Horse

http://www.crazyhorsemotorcycles.com/

Texas Bike Works

www.TexasBikeWorks.com

Kustoms Inc.

KustomsInc@hotmail.com

Chop Docs

www.Chopdocschoppers.com

3 Guyz

www.3Guyz.com

Accel

Accel-ignition.com

Fab Kevin

http://www.fabkevin.com/home.htm

.jpg)

Evil Engineering

www.evil-engineering.com

D&D Exhaust

http://www.danddexhaust.com/

Wire Plus

http://www.wire-plus.com/

Barnett

Barnettclutches.com

Rocking K Custom Leathers

howard.knight@montana.com

Rivera Primo

www.RiveraPrimoInc.com

Spectro Oils

www.Spectro-oils.com

Bell

www.moto@rcn.com

Metzeler Tires

www.metzelermoto.com

.jpg)

Hawg Halters

Handy Industries

www.HandyIndustries.com

Grip Ace

www.gripace.com

Biker’s Choice

www.bikerschoice.com

Aeromach

www.aeromachmfg.com

Ride Wright Wheels

www.ridewrightwheels.com

Biker Pros

www.BikerPros.com

Bare Knuckle Choppers

www.bareknucklechoppers.com

Timbo’s ’64 FL Restoration (Part Two)

By Robin Technologies |

1964 was an interesting year for Harley. it was the last year of the 6-volt electrical system, and last year for the kick-start only. In 1965 they stepped up to 12-volt system and the first electric start and massive batteries started to appear. So let’s get started, I removed the primary, to my surprise it had a belt drive in it.

Someone wanted a step-up from the original chain drive, unfortunately it’s covered in oil that leaked from the main shaft seal and chain oiler that was never shut off. I might be able to save it with a healthy cleaning, we’ll talk about that later. After removing the primary drive and clutch, I thought the transmission would be a good place to start the restoration.

I did the research and found out all the parts I needed to rebuild the stock 4-speed transmission were available from J&P Cycle, and manufactured by JIMS. So off to the catalog I went. I ordered all the gaskets and seals I needed to rebuild it, except one, the main drive shaft seal (which was the worst one out of the bunch). According to the manual and other people I talked to, you need to invest $250 in the special tool from JIMS. It removes and installs that seal. However, I found an old friend (older than I) sorry Danny! LOL, who knew how to R&R the seal without the so called special tool, no big deal, according to him!

Be careful not to lose the gear shaft key for the sprocket. Also, there’s a small keeper key (looks like a flat L). It holds the sprocket far enough away from the seal, so it doesn’t ride on the seal. Keep it just in case. I later found out the new seal came with the keeper, but it’s better safe than sorry, if ya know what I mean.

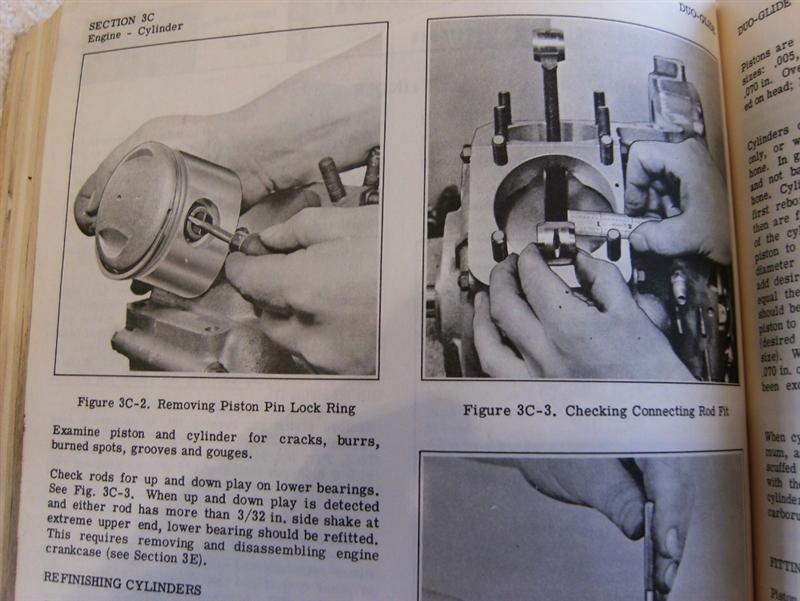

There are some measurements you can take with feeler gauges for the shifter forks and spacers, refer to the manual.

Also you can check the timing shifter notches for alignment after the cover has been removed, also in the manual.

I actually ended up with two manuals, the original 1964 Harley service manual and a Clymer manual. Out of the two, I prefer the original service manual, it’s so easy to read and understand an idiot can follow it. Wait a minute! It’s also a good notion to pick up a parts manual for a variety of parts illustrations not found in service manuals.

For the serious rebuild the Wolfgang Panhead Restoration book, by Rick Schunk is an excellent guide. We were fortunate to have a low mileage transmission, and only a clean- up was required.

All the schematics are hand drawn in detail, very cool and definitely vintage. For the main shaft sprocket seal, I used the old school method my friend suggested, a slide hammer. Simply drill a couple of 5/32 holes in the seal, not too deep, about ¼-inch, screw in a sheet metal screw, and slam away!

It came out on the second slam of the hammer, YEAH! Installing the new one was just as simple, add a little Vaseline or WD40 to the outside of the seal and gently and evenly tap it in. I used a brass seal installer I had lying around, moving it back and forth on the seal so it doesn’t bind. Tap it down flush with the case, and your done. The JIMS tool insures that the seal is installed perfectly square into the case.

The rebuild kit came with all the gaskets and seals. There’s an O-ring seal in the kick-start shaft that rides between two brass bushings, be sure and replace it.

You can reach in with a dental pick or small screwdriver, and remove it without pounding out the bushings. The kit comes with new gasket for speedometer cable and neutral light indicator.

I polished up all the chrome it had and added a brass kick-start pedal, it looks great! Yeah, I know, not OEM pedal, but it looks cool and is pretty close to the era. I also ordered all new chrome case screws, the old ones were rusted, plus the chrome looks better anyway. I painted the inner timing cover and polished the out cap. You will find that almost all the transmission and engine cases are cadmium platted.

Lots of guys polish or chrome them, my customer wanted them to look as factory as possible. Here it is, the finished product. Not sure what I’ll tackle next, if you have any requests, let me know, I’ll be glad to accommodate. I’ll probably go right into the engine. That’s all for now, Tail Gunner out till next time.

Rivera-Primo Brute II Install

By Robin Technologies |

We have a goofy Shovelhead in the Bikernet shop called the 1928 Shovelhead. It has 21-inch wheels front and rear in a Paughco rigid frame, but some 1928 elements were used, including the re-pop semi-flat sided tanks, the rear fender and perhaps the seat. The bike was conceived by Bandit the bastard, built by the crew at Rick Fairless’ Strokers Dallas, with the help of Randy Simpson who manufactured the handlebars.

The bike has contained a couple of hiccups and hasn’t been ridden much. Recently, one of Bandit’s friends needed a ride, so Bandit shipped this puppy to Washington. Richard Kransler installed new Avon tires and took it out for a spin. Unfortunately, the early Rivera-Primo belt, stuffed into the semi-stock inner primary, snapped and the 1984 Shovelhead was garaged. More recently, Richard concocted a deal with Bandit for a van in exchange for his Sturgis Shovel, and returned the 1928 Shovelhead to the headquarters, where the gang went to work on it.

With Richard’s info, and after consulting with Ben Kudon at Rivera-Primo, a plan was put into motion to make this wild puppy more rideable. We needed to add an oil filter, rerun the oil lines to reduce heat, fix the sumping problem, replace the primary drive, and then we discovered a loose valve seat, but we’ll get to that.

This is also a two-part tech. We first installed the Brute II Extreme Belt drive with a 1 ½-inch wide 11mm belt with electric start in the closed primary. Then we will install the most magnificent Rivera-Primo Pro Clutch. Since this is a jockey shift, it will be interesting to test both the stock clutch against a new clutch system that’s state of the art. We will forward all of our extensive reports directly to the boss and all Bikernet readers.

We discovered immediately that the front Brute II pulley was larger than the previous model, which was disappointing because it called for more clearance in the case, which weakened one of the primary fastener locations. Not a big deal, so we went to work with a pneumatic cut-off blade and emery wheels.

It’s critical to disconnect the battery, especially while working on the inside of any Shovelhead primary. It’s too easy to bump or pull on the starter solenoid, and you could lose a finger pronto. Fortunately, we have a selection of JIMS tools and pullers for this operation.

Here’s the fine print from Rivera-Primo: Primo Belt Drives are designed and engineered to correctly fit stock Harley-Davidson motorcycles. Aftermarket frames, primary covers, engine shafts, or clutch hubs may cause installation problems. Also bent frames, sagging motor mounts, worn transmission mounts, and other defects may cause shortened belt life due to incorrect pulley alignment.

If you have a stock system being replaced, here’s the dope: Remove the front pulley, chain, compensator and chain adjuster. Remove oil lines to primary and plug or clamp to prevent leakage. Cut the chain oiler hose 3 inches from the oil pump and permanently plug it. All belts must be run completely dry, without lubrication of any kind. Therefore, remove all oil from inside the primary covers.

The spacer behind the front pulley should be removed before installing the belt drive. This spacer may or may not be required to correctly align the pulleys. If a spacer is needed for alignment, various sizes are available from your local Primo-Rivera dealer (part number PX-1, is a package of various sizes).

We discovered a very tight belt. We had to carefully install the belt in the case first. Then the front pulley was installed onto the main shaft, but just slightly to afford us some flexibility with the clutch hub. We re-greased the bearing on the clutch hub and inside the clutch shell. With the handle of a plastic hammer, while prying it with a large screwdriver, we were able to drive the clutch shell over the hub with some gentle persuasion.

We tracked the belt, and installed the same spacer from the last system behind the engine pulley. With the bike jacked and the plugs pulled, we turned the engine over to test the running direction. We made sure to run the engine over in a forward direction. It’s not a bad idea to use a straight edge at first to make sure the pulleys have the proper spacing.

“Spacing the motor pulley outward will cause the belt to track towards the outer primary cover,” said Ben. “If spaced too far out, the belt will rub on the inside of the clutch shell.

Then we attempted to install the outer, aftermarket tin cover and discovered a significant problem. It rubbed against the clutch shell. So far, our inner primary clearance adjustments worked.

We were concerned about the tightness of the belt. It seemed severe to us, and to Bandit. According to the Brute II directions, the belt requires a minimum of ½-inch up and down play at the center of the belt, and up to ¾-inch. We barely encountered ¼-inch of tough play. “Free play is critical,” Ben said, but when Bandit questioned him, he muttered something about ¼-inch being okay, since the belt was so stiff.

The crew even considered replacing the system with a stock chain, to avoid issues. We took the system apart and studied each element, and investigated. I looked into a longer belt, or installing the earlier unit again, which had its benefits with the smaller engine pulley and tapered clutch shell that fit in the primary. We installed the belt again and tested the flex—still tight. We cut a hole in the tin primary, eliminated that problem and affording us tremendous venting. We live and breathe by the Optimist Creed, sort of code of the west. We are hoping once the belt settles in and warms, we will encounter additional flex and no stress on the engine and trans bearings.

“This is a much stronger, more technically advanced belt over the previous 14mm belt,” Ben assured me. We will give it a shot. Venting is a critical element. Primo recommends venting enclosed belt installations to allow cool air to circulate into and out of the primary case. This will keep heat expansion to a minimum and extend belt life.

Special Note: Big Twins from 1969 require a #16657 motor seal. Next we will install the new Pro-Clutch from Rivera Primo and test it, so we will be in and out of this primary case and reporting back on our findings.

In the meantime, we rerouted the oil lines, added an oil filter mount, and an oil pressure gauge for more capacity, cooling, and cleaner oil. We worked on the sumping problem, and then discovered that a valve seat was loose in the rear head. We pulled the heads and delivered them to Branch O’Keefe for repairs.

Our shop intern and overall handy-man, Kyle Olsen, our official Bikernet electrician, will test this bike. We are determined to make it a solid rider, and Kyle will bring us reports and handling complaints in the near future.

We modified the jockey shift and added the 5-Ball for easy shifting that’s out of the way of our thighs at stops.

And Bandit has a code, a good one. All bikes need rear chain guards, and this bike doesn’t have one. We will remedy that. Plus we have a brand new set of Nology plugs and plug wires to install. Hang on for the next report.

Timbo’s ’64 FL Restoration (Part One)

By Robin Technologies |

Not too long ago, my good friend Timbo approached me with a proposition, restore his 1964 Harley FL, I agreed. Problem was, it’s in a box, literally! So after a brief discussion on exactly what we wanted to do, how much it would cost and the possible value at the end of the rainbow, I started the Hard Ride back from Hell with the old ’64. I picked up the bike, basically a roller and all the boxes of parts that came with it. As you probably expected, this will be a frame up restoration as close to factory specs as I can get it.

There will be some minor changes, which I’ll talk about as we go along. First thing was to lay it all out and take inventory to see what was missing. After some research, I found replacing parts for the ’64 surprisingly easy thanks to J&P Cycle, Biker’s Choice, and the internet. I ordered the Vintage catalog J&P Cycle puts out and started researching parts I needed to replace.

I also found a local polishing company and chrome hardware supplier (needmorechrome.com) to make life easier. Tear down was a snap. Make sure you bag or box all your parts as you go and label what they are, and in some instances what order they go in. It’s not a bad idea to take lots of photographs for future reference. Sometimes a parts manual comes in handy.

After tear down, I started the fun stuff, going through each and every part, each nut and bolt and cleaning them. Some parts and hardware will not be salvageable, so you’ll have to replace them with either new, or good condition used. I found that there is a tons of vendors on line for just about everything you need. Buying new parts from the catalog is not always the best answer, especially if you’re on a budget like I am.

So shop around, do some research, you may be able to save as much as 50% sometimes. You will also need repair manuals and a few restoration guides like the one my friend Bandit sent me for reference from Wolfgang publishing, thanks Bandit. It has been very useful so far. This is the first of many articles on this restoration project. As the months progress, I’ll try and give you a detail look at what’s involved with a full-blown restoration.

Tail Gunner out for now, see ya next month!

Doug Coffey’s RetroMod Panhead Part 1

By Robin Technologies |

Other than the missing sidecar sidecar loops, it has a strong resemblance to a 1957 straight leg rigid frame. Exactly what I wanted.

Mudflap Girl FXRs, part 11: The First Road Test

By Bandit |

Mudflap Girl, chapter 10: http://www.bikernet.com/pages/Mudflap_Girl_FXRs_Part_10_Suspension_Tuning_and_Le_Pera_Seat.aspx

I can’t make it to Sturgis this year. We are focused Bonneville builds, like mad starving dogs, and the two events are only separated by two weeks. Ray is tuning and I still don’t have an engine, but we’ll cover that later. The engine could be running today, in Richmond, Virginia, at Departure Bike Works.

Okay, so what’s a poor bastard to do, when he planned to make the run to the Badlands with his brother Hamsters? They ride out from the West Coast every year. Some of the members, including Arlen Ness are in their 70s and riding custom Victory bikes. Some rode from Spearfish, South Dakota, out to Mammoth Lakes, California, to ride back to the Badlands with their brothers. So, what’s the least I could do? Meet them at their first stop in Mammoth, just east of Yosemite?

The good doctor has owned several motorcycles, including a 1934 VL I helped get running, but one motorcycle stuck with him, a 1989 FLH. He had clocked over 200,000 miles when he decided to rebuild it. Bennett’s Performance handled the semi-stock Harley engine (the rebuild was covered on Bikernet). With a couple of thousand miles on his rebuild, and 50 on mine, (another 80-inch semi-stock Harley engine, assembled by S&S, with headwork by Branch O’Keefe), we rolled out of Los Angeles.

About 15 million folks know rolling out of Los Angeles is the biggest challenge to any weekend excursion to someplace less congested. It’s amazing, like no-man’s land at the front of any war zone. Just try to slip out of Los Angeles on a Friday. Try to peel by noon or before. If you don’t you could be faced with serious bumper-to-bumper malady, or a lane-splitting conundrum. We recently published a report about splitting lanes and the benefits. They actually made a case for increased safety in areas supporting lane-splitting.

I’ll make one case for the freedom to split lanes, maybe two. Well actually, the published study pointed out the benefits of keeping motorcycles moving during high-congestion back-ups. My point included any rider’s sense of alertness. When splitting lanes the rider’s acute awareness is on high alert. Even while putting past a myriad of parked cars, a brother never knows what could blink, so his senses are hot wired. He or she is aware of anything that moves, from a slight wheel shift, to a nod, or a turned head.

So, I split lanes as soon as I hit the 405 freeway, off the 110, the oldest freeway in the US. It runs directly into the heart of Los Angeles, downtown, from my digs in the Port of Los Angeles. As I pulled out of Wilmington, two concerns stirred my humble sense of motorcycling comfort. First, I discovered my rear chain smacking the Spitfire hand made oil tank. There was always a bothersome noise bugging me, and I finally discovered the treacherous origin, the rear left corner of the FXR-styled, rubber-mounted oil bag.

Fortunately, the Spitfire team had welded a threaded bung into the corner, and a tab off the frame. I ran across the problem during assembly and removed the tab for more clearance, but evidently not enough. So the night before the run, I removed the chain, cleaned the threads with a tap, and made a countersunk Teflon bumper to protect the tank, but would it last? Or would the chain disintegrate my protective barrier, cut a hole in my oil tank in the middle of the Mojave Desert, dump all my oil onto the highway, seize up the engine, and leave me to be tarantula bait, after I baked under the 107-degree blistering desert sun?

I also made one final adjustment to my Wire Plus speedometer sensor stuffed into the JIMS Screamin’ Eagle over-drive 6-speed transmission. I had tried everything. I was at a strange juncture. It’s been so long not working, if it worked I would have been shocked. As I pulled away from the headquarters, I wasn’t disappointed. It still didn’t work. Now, I have another idea. I didn’t connect the wire from the sensor to the speedo wire directly, but to a connection board. Maybe a direct connection would be the trick.

Somewhere in the sizzling desert, with the afternoon sun baking my feeble skull, the notion of this road test article was spawned. The Mudflap Girl FXR contained only 50 break-in miles so far; this 700-mile jaunt would be the iron test. I had followed the Eddie Trotter break-in regime, almost to the tee. With each longer and longer ride, I returned to the headquarters to make corrections, repairs, and adjustments. It was time for the acid test, a long road into one of the hottest regions in Central California, a total round trip of perhaps 700 miles in 2.5 days. That’s a big deal for this old guy.

There I was, splitting lanes across the LA airport toward Santa Monica and the good doctor’s office, where he was leaning over his knockout secretary and adjusting a tall tattooed redhead. Tough job. Sticking around his office near the coast, with a bottle of something, would’ve made my weekend.

Oh, one more concern disturbed my peace of mind. I started to write peach. I was still with the girls in the office. I hand-made the two mounts holding the single RockShox to the girder. My mind whirled with 80mph impact, a bottoming out shock, and the stress on the mounts. Would they last or toss me into the fast lane of a crowded Los Angeles freeway? Ah, for the days when we would build a bike, smoke a joint, down a shot of whiskey and ride some half-wired together chopper across town at breakneck speeds to her house. Hell, we felt so good, it didn’t matter if we made it our not.

While parked at the good doctor’s office, I inspected my Teflon pad. It was sliced severely, in just 40 miles, but the next 40 or 100 would finalize the experiment. My shock mounts hung tough, but what about the next 100 miles? We gassed up and peeled out onto a crammed 10 Santa Monica freeway. Splitting lanes and dodging merging traffic we weaved onto the 405 Freeway. It peels over the notorious Sepulveda Pass, into the San Fernando Valley, and beyond toward the 5 Golden State, high-speed direct link from Los Angeles to the bay area and San Francisco.

We just needed to cut across the 101, to the 5 for a five-mile stretch, and then off on the 14 toward the Mojave mile airport landing strip and land speed trials location. I felt every bump and groove in the crappy road as I leaned into the fast lane and poured the coals to this 80-inch beast. It ran sweet. I set up the dual-fire, Compu-Fire ignition according to instructions, and installed the Trock modified CV carb, but never adjusted any aspect of it, except the idle.

The week before we peeled out I rode to Bennett’s Performance and Eric popped the cap off the air fuel adjustment behind the float bowl, and adjusted it—it was too lean. Trock removed the cap, so the adjustment screw was operational. I rode the bike, noticed an intermittent cough, and called Eric. He recommended backing out the needle one-quarter turn. She seemed happy, and in Mojave we refueled and checked our mileage against Christian’s trip meter. We had covered 90 miles and I reloaded with 1.82 gallons for 49.45 mpg. It pulled well in any gear, even in sixth gear. The JIMS Screamin’ Eagle Overdrive transmission shifted like butter and never missed finding neutral. I geared it slightly high for a 6-speed with a 23-tooth trans sprocket and 51 on the rear wheel.

So far, we flew along big wide freeways through the Soledad Pass, Palmdale, Lancaster, and then into Rosamond. At over 90 degrees, the freeway started to die and turn into a two-laner along-side the Pacific Crest National Trail leading into the Sequoia National Forest. It looked sorta bleak and hot to me, as I pondered the welds that held my chopped Spitfire bars together. So far, the riding position was a dream. My legs were stretched out nicely. I could move around on the very comfortable gel-impregnated Saddlemen seat with the spine relaxing channel, and just a touch of lumbar support. The bike handled well, as I adjusted to the long bike vibe.

Another rambling rural 50 miles in the desert with only rolling hills in the distance, and the 14 Highway disappeared to be replaced with the well-kept Highway 395 in Indian Wells Valley. We passed more deserted truck stops, than active ones. They were extreme sun-dried out buildings. Chipped paint was sandblasted by desert winds, and busted windows gave the dilapidated structures, gradually turning to dust a war zone appearance. I set the bike up to be a chopper for the long road, with rubber H-D pegs, old styled thick rubber Knucklehead grips, and Custom Cycle Engineering rubber-mounted traditional dogbone risers. Since the drive train was rubber-mounted, it all worked to minimize vibration.

We followed one billboard to an old gas station turned into jerky sales headquarters. It bragged “Good jerky.” It was actually so-so, and small packages were priced at nine clams. I wanted to support their sticker-scattered cause. The smiling Hispanic broad behind the counter gave me the okay to plant a Bikernet sticker on the building, yet I couldn’t cough up nine bucks, plus tax for a bag of so-so jerky. We peeled out.

Just a handful of small towns peppered the highway with reduced speed signs, some as slow as 25 mph, perhaps a fund-raising effort. We rolled into Lone Pine and the Dow Hotel, which was packed with tourists and bikers heading to Sturgis. The Dow, built in 1923, was specifically constructed to house movie crews, since a large number of westerns were shot in the region. What a roll of the dice, but it paid off. We topped off and compared notes this time. We had sliced through 111 miles and I took 2.3 gallons, for 48.3 mpg. The doctor grabbed more fuel between stops, so he crossed 38 miles and took 1.2 gallons for 31.6 mpg. He was disappointed, and we discussed options for the future.

The good doctor noticed some drops of oil on the pavement next to my bike. My oil cap isn’t correct for the screw-in bag bung, so I found a press-in rubber cap, with a small dipstick. It worked, but loosely, and a small amount of oil seeped onto the roof of the Spirfire steel oil bag, then some trickled down the right side, onto the frame and dripped onto the pavement. I pressed the oil cap deeper into place and check the oil level, and then it dawned on me. I noticed a softening in my rear GMA brake action. That was the cause.

[page break]

I checked the Teflon pad, and it didn’t indicate any more chain damage, plus the tank was well clear of the carved edge. It appeared very secure, and my shock mount held fast. Vibration was minimal, and at every stop, folks confronted me about the Mudflap girl bike, the traditional chopper appearance, and almost every onlooker said, “Is it a rigid?”

The next morning, we faced just 99 miles for our meeting with the evil Hamsters at the Westin lodge in the heart of Mammoth lakes. The roads were perfect and our 80-inch Evos purred as the elevation increased from sea level to 4000 feet, and we were expecting another 4000 thousand and more pine trees as we cut a dusty trail toward the Sierra Nevada Mountain Range, just east of Yosemite. We stopped in picturesque Bishop for breakfast, but the two hot spots were jammed. We strolled into Whiskey Junction without a problem, then rode the remaining 40 miles to the Mammoth cut-off. I was expecting winding, twisting mountain roads into the mountain/sky resort community, but it was virtually a straight shot. My memory reminded me of a similar stop the year I hit a deer inWyoming.

We didn’t pop for the high-dollar rooms, but stayed down the street at the Sierra Motel, where the doctor pointed out a concern with his front wheel. We rode up the street to hang with the Hamsters as they rolled in as early as noon. Some rode in from Spearfish, but the Bay Area contingent, including Arlen Ness chose to fight traffic in slow lanes through Yosemite National Park. They weren’t scheduled to arrive until the early evening, so we returned to our digs to take a look at his front wheel. Under the backdoor hotel overhang, we found a massive cinder block, jacked up his FLH and removed the front axle. One of the bearings demonstrated serious damage and we attempted to remove it with the help of the Hawaiian biker handyman.

We easily had enough tools between my Bandit’s bedroll and the doctor’s tool bag. Concern grew as we discussed our issue with other riders, and Ted Sands, from Performance Machine. “Did you powder coat the wheel?” Christian scored a couple of late model Twin Cam, 1-inch axle mag wheels, powder coated them, and replaced the bearings with ¾-inch axle jobs, but there was some question about the internal spacer. The spacer needed to be solid against the inside bearing race, and that didn’t seem to be the case. The left bearing demonstrated serious wear. We started to make calls.

The Mudflap Girl bike handled the roads to Mammoth extremely well, although we are hoping to step up and buy another RockShox with at least 2-inches of play and a 250-pound rated spring for testing in the future. I’m sure with the correct resources, we can make this girder ride like a Cadillac. I ran into one problem with the Mudflap girl. The left stock H-D foot peg with massive rubber padding for comfort, wanted to slip off the stem and depart. I thought this bastard wouldn’t budge, but I continually fought it.

We called for local bikes shops, but it was Saturday night and resources were limited. Christian made a run on my FXR to an auto parts and bought a jug of bearing grease, a spray can for chain-styled foam lube, and a small container of Buffalo-snot glue for my peg. I actually needed rubber cement, but gave it a shot.

“The FXR Chopper is one great looking scooter, with just the right stance to have attitude, without being obnoxious,” said the Doctor. “Everyone twists their neck when she goes by.

We operated as best we could on the doctor’s wheel but could not remove the bearing to correct the inner spacer problem. We packed that bastard full of grease and called for a U-Haul truck rental in Bishop for the next morning. The final question: Could, would, should the good doctor risk riding his Bessie down the hill? We confirmed with U-Haul; the regional office would open at 7:00 a.m. The Bishop franchise opened at 8:00 a.m., and a 14- foot box truck was available with a ramp. We would need to score a batch of tie-downs.

We returned to the Westin to hang with our brothers, Buckshot, a Bikernet and Thunder Press contributor, and Marilyn Stemp, the editor of Iron Works. That’s when Ted Sands told us about the drawbacks of powder-coating the interior of late model hubs and the impact on bearing spacers—bad news. I rode the FLH, and it rattled like marbles in an empty tin can, but I didn’t sense any grinding in the bearings. I didn’t want to make a recommendation. This had to be his call. Then I mentioned the 40-mile distance to Bishop. He was thinking 100 miles to Lone Pine.

By the way, we gassed in Mammoth for another 98 mile run. My bike was feeling the pain of reduced oxygen at 8,000 feet, and the night would drop to 41 degrees, but she still ran well. I struggled to squeeze the nozzle into my tank and loaded it with 2.5 gallons (39.2 mpg), and the doctor refueled with 3.2 gallons (30 mpg). He will look into a jetting change for his S&S carb.

As we hit the hay, the doctor decided to attempt the slow ride to Bishop. We set the alarm for 6:30 and tried to sleep.

The weather was amazing, just a tad cool in the morning as the sun slipped between pine needles to warm the streets. We packed and rolled down the hill to the first coffee shop. We were gassed and ready for the 40-mile delicate, risky ride to Bishop, a town of 5,000 along 395 just below Mount Whitney, the highest mountain in the continental United States. We were so focused on surviving the Bishop run, we didn’t think about the cool breeze, my wandering peg rubber, or any distraction. I’m sure Christian was as tense as an over-tightened drive chain as we rolled serenely down the mountainside onto 395 south at 45 mph.

“Going 40 miles down the hill towards Bishop was a bit nerve wrecking, since the bearings were grinding and clackering like marbles in a bag being tossed on the ground!” Said the doctor.

The good doctor rode almost 20 miles, his hands, like vice-grips on his bars waiting for the bearings to scream and spit from their housing. The hefty front mag would wobble, then lock against the twin Performance Machine 4-piston front brakes and scream for relief, maybe locking up and tossing the doctor and his gear in the weeds. I asked him to ride on the right for easy access off the road, just in case.

“But after about 20 miles the sounds and noises started to be less and less,” said the doctor. “Once we got to Bishop it had subsided 80%!!!!!”

We arrived right on time, and spotted a women in the U-Haul yard. “They don’t open until 11:00.” Her husband arrived and confirmed the bad news. Disillusioned, we rumbled into town for a hearty breakfast at Jack’s and made a number of phone calls. If we could make it to Mojave, we could find another U-Haul, but then we would only be 100 miles from home. The Doctor could ask his girl to meet us there with a trailer. He called U-Haul, bitched and sought alternatives. None were forthcoming.

We said, “Fuck it,” and kept rolling. With each 50 miles, his confidence grew, but we remained at a mild pace of 60 mph, them 65. I finally got fed up with my spinning peg rubber and pulled off the side of the road and strapped it down with tie-wraps, pulling them damn tight.

“Do you want to cinch them down with a pair of pliers?” said the good doctor.

“Nah,” I responded. “We’re good to go.”

Yeah right. The sonuvabitch still squirmed and tried to escape. At the final refueling stop in Mojave, I broke out the pliers and pulled those tie-wraps as hard as I could. The bastard never moved again.

The doctor, comfortable with his FLH, resigned himself to flying into LA by himself. I would cut off at the 210 and dodge the rough, jagged, concrete 405, heading directly into one of the most congested intersections and construction zones in Los Angeles, the 101 junction, over the Sepulveda Pass to the 10 Santa Monica interchange. I could fly into the city on the foothill freeway against the San Gabriel Mountains into Glendale, cut south on the Glendale freeway for just 10 miles and pick up the 5 for one mile before I jumped onto the 110 south directly to my door through downtown Los Angeles.

As I peeled off the 5 at the 210, Christian gave me a final thumbs up and rolled into congestion for just another couple of miles, then cut off at the 405. It was just about 3:00, the bewitching hour, before a city of half-drunk yahoos, talking on cell phones and playing grab-ass with their girlfriends, headed home from barbecues, weekend camping beer-soaked outings, cantinas, bars, ballgames, you name it. This is the most notorious crew of inexperienced drivers, on unfamiliar freeways, buzzed, and distracted, heading home after too much fun. This group of millions, in tin overseas boxes and SUVs, with stereos blasting, is in contrast to commuter traffic, made up of professional, daily migrants, who know every inch of their incessant trips back and forth to work.

Both Christian and I have ridden LA freeways for over 35 years. We both rolled into our respective digs within 20 minutes of each other and checked in. Within an hour and after my first Jack on the rocks, I wrote some compliments and foreword thinking thoughts to Paul Cavallo, the Spitfire master, and he immediately responded:

“Hey brother, good to hear from you. Glad you had a great ride,” Paul wrote. “I have you covered on the oil cap. I just finished up a re-design on the girder trees that eliminates the shoulder bolts. I will update yours to the new gear.

“Bill Dodge rode his out from Kentucky for Born Free, and loved the ride, but after a 5,600 mile round trip, those little thrust washers wore thin. I doubled the strength of all of the pivot components, and machined pivot pins into the trees, and cross bars. I even designed a retro kit for all of the existing front ends.”

We discussed RockShox with increased travel, and I also mention raked trees for better cornering. The more you rake a bike, the more it wants to go straight, which hinders cornering. Bikers generally love to corner, and I discovered, with my blue flame that even a chopper can corner with adjusted frame geometry.

“When I update your front end, I will give you 3, and 6-degree links for it,” said Paul in his response. “The girder is so easy to change the rake on.”

There you have it. The first 700-mile distance test of our Mudflap Girl FXR. Scooter Tramp Scotty is right on: Evos Rule and Choppers never die.

Spitfire

D&D Exhaust

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Progressive Suspension

Timbo’s ’64FL Panhead Part 3, Engine

By Robin Technologies |

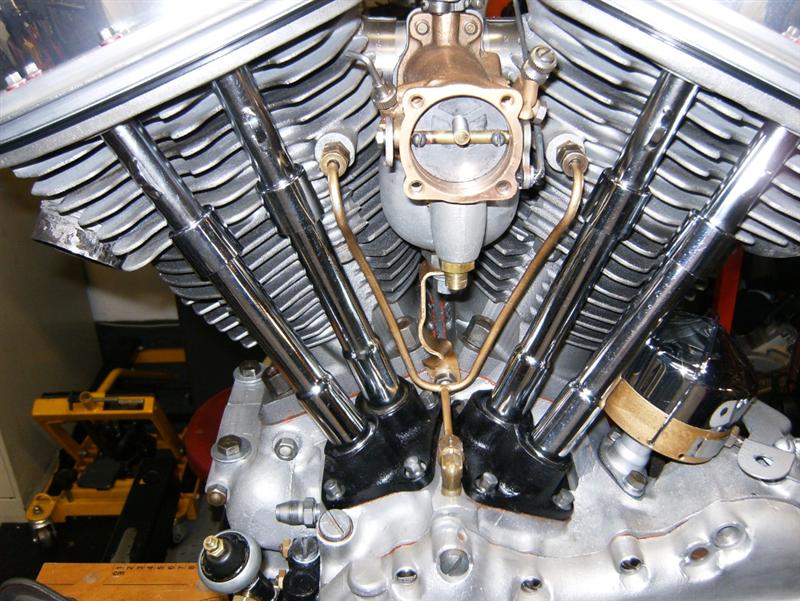

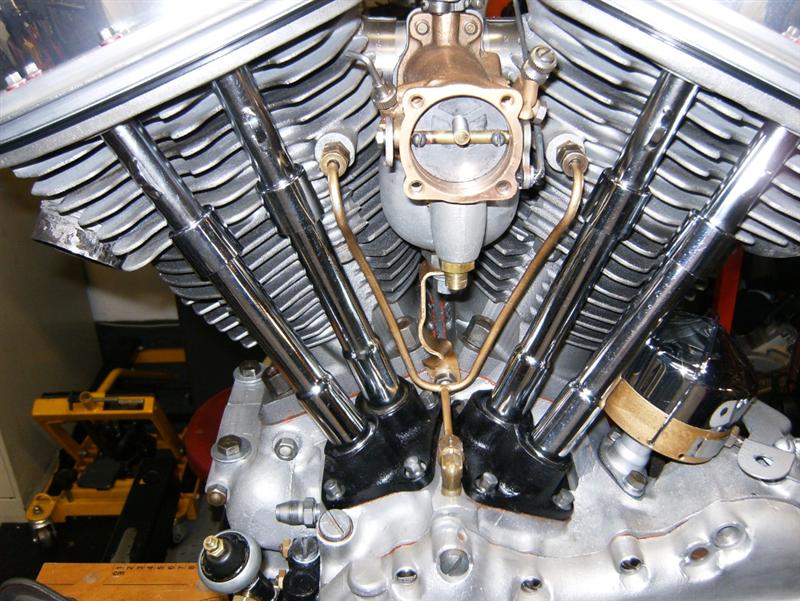

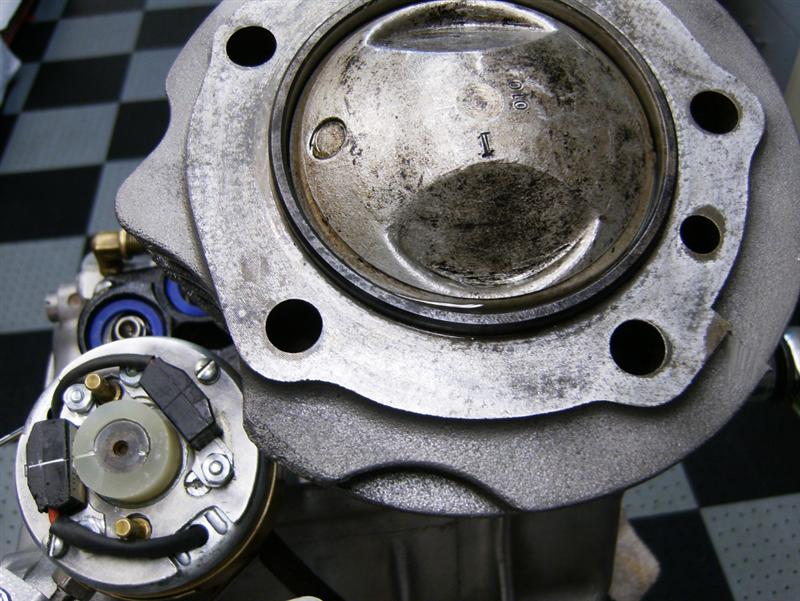

Tear down was straight forward, first I removed the carburetor, followed by the oil pump, gear drive housing, push rods, tappet blocks, rocker covers, heads and barrels. After the barrels have been removed, place a couple of shop towels around the connecting rods to keep debris from falling into the crankcase.

I carefully cleaned all old gasket material from all the mounting surfaces. I ended up using razor blades and plastic scrapers. Be careful not to gouge any mating surfaces as you scrap. Any abrasion could create a leak if the gouge is deep enough.

You can follow the generator instructions in the manual. It’s extensive and takes patience, but not overwhelming. I just hope it works, as a new costs around $400! Ouch! I also found “Rene “at National Starter in Lancaster, California. He Put the 6v through its paces to make sure we have a strong working unit, Thanks Rene!! The old mechanical voltage regulator was replaced with a new solid state unit and the OEM dual point circuit breaker was replaced with a state-of-the-art electronic dual contact unit from Quick Start 2000.

Ed from Quick Start custom builds electronic circuit breakers specifically for vintage motorcycles, and he spilled a wealth of knowledge, always willing to help in any way he can, yea ED!!!!

Rebuilding the oil pump was a simple task, you can get the complete kit from J&P Cycle. The gear case cover was removed and the timing marks were checked for alignment.

I removed the tappet blocks and tappets, cleaned them and miced them to see if they are within tolerance, they are. Be careful when reinstalling the tappets, they need to go in the same position (same hole) they came out of, with the oil passages near the rollers pointing inward (refer to manual). Failing to do this will cause the engine to seize, and we don’t need that.

Timbo wanted the barrels to be blonde, so I had them bead blasted to remove the black Bar-B-Q paint someone had put on. In my opinion, they look way better blonde. As far as the heat transfer, I don’t think it makes much difference. Most Harley engines of today are blonde, the black is a cosmetic option. I have built aircraft engines for 20 years, and almost all are bare metal cooling fins. I coated the bare metal with clear 1500 degree heat paint, just to make sure they don’t rust up on me.

We can argue the “black heat dissipation thing” at a later date! For the barrels and heads, they suggest you purchase a special wrench to ease installation and removal. I found a little patience and a standard 9/16 and 5/8 box end wrench and 12-pt. deep socket worked just fine for removing the barrel and head bolts. I was fortunate to have the original manual, a Clymer manual and a cool restoration book sent to me from Bandit.

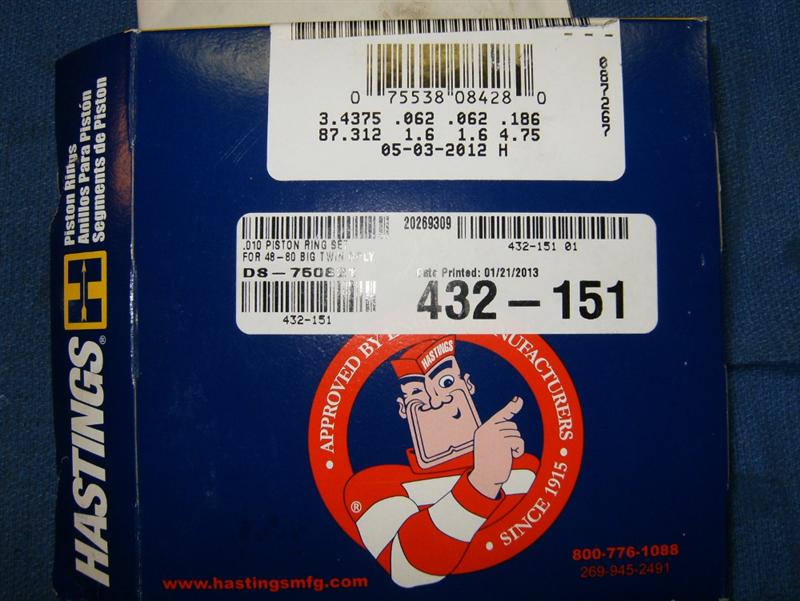

New rings installed along with the cylinders cleaned and honed. The heads looked really nice, no gunk had built up yet and the valves were lapped just to make sure. I also cleaned out all the oil passages, don’t want any debris mucking things up!!

At last, the engine is complete for now. Since beginning this article, I have already installed the engine and trans in the frame, another article on the frame will follow soon.

Tail Gunner out for now!

1964 Pan Head part 4 (frame)

By Robin Technologies |

Oil tank and lines were next on my agenda. I opted for a more modern spin on oil filter adapter, it looks nice and makes oil changes a snap. I kept the original oil filter that was polished just in case the owner wants to go all original some day.

The front forks have been completely rebuilt with all new modern seals, I had them polished also, looks nice! My customer decided he wanted a old school look on the wheels like they did in the ’30s and ’40s, so we blacked out the spokes and hubs leaving the star bearing plates and lug bolts the original parkerized coating.

Just about everything that is aluminum was polished like chrome. We kept to the OEM look on the primary and oil tank, which was black with touches of chrome.

As for the clutch shift linkage (mouse trap), it also was completely gone through and restored, polished and looks like new. I did find out why they call it a mouse trap! Got my Fuckin’! finger snapped twice while trying to adjust it, IT HURT BAD!

The brakes have all new shoes, lines and fittings. Front brake is mechanical and rear is hydraulic, all juiced, adjusted and ready to go. Tires we picked are replicas of the day. They are Shinko reproduction white walls. Not the best, not the worst, but fit the budget just right. They have all new tubes, rim belts and have been balanced and trued by me.

The new exhaust went on comfortably with new head clamps. We kept the original muffler. It was salvageable. All the footboards have been rebuilt with new rubber and rivets and foot controls were installed.

The original generator in chapter 3, was a no go, it had a bad armature and wasn’t cost effective for a rewind. So I ordered (cust. request) a new 6v generator with built in voltage regulator, it too looks very nice. Just a quick rundown, the electric system although all 6v, has all new solid state components i.e. electronic dual breaker distributor with a solid state voltage regulator, no mechanical parts.

The electrical has all been installed and wiring is complete less the head light and tail light. Both electrical junction boxes have been rebuilt with new insulators and wiring harness.

There’s a lot of little things like the $5 chrome chain guard I found at the swap meet and some odds and ends I also found in good condition cheap, at the swap meet. You can see them in the photo’s if you look hard. The steering head lock was a nightmare. It took me months to track one down on eBay. Shortly after I purchased the one on eBay, JP Cycles informed me that they finally had one in stock, go figure!

Mudflap Girl FXR Part 12—She meets S&S

By Robin Technologies |

Here’s the link to Mudflap Girl Part 11: http://www.bikernet.com/pages/Mudflap_Girl_FXRs_part_11_The_First_Road_Test.aspx

My son’s Mudflap Girl FXR is running and partially broken in. I even, finally, dialed in the Wire Plus Speedometer, and it’s working. I wish I knew what I was doing wrong, but that puppy works like a champ. I enjoy the tightness of the display and ease of installation. In that small cylindrical Wire Plus display, I get a speedo, a tach, trip gauge, neutral light, turn signal indicators, oil idiot light, and what else?

Okay, so it’s time to turn the Pro Street version of the Mudflap over to my son, Frank, but first we couldn’t leave the bone stock remanufactured 80-inch Evo engine alone. I reached out to S&S for a cam recommendation, and they recently built a relationship with Crane Cams.

Bruce recommended the following stock engine formula: S&S Super E carb, Crane Hi-4 ignition, S&S Cam and S&S easy-adjust pushrods, a Crane dual-fire coil, and the S&S 33-4250 breather and shim kit, for just enough pump to let this motor breathe.

I hauled the Mudflap beast on my Kendon tilt-up combo trailer to Bennett’s Performance, a very clean shop, next to Branch O’Keefe Flowmetrics, on Signal Hill. Eric Bennett, the boss, bought the Bikernet Hearse, immediately fired his girlfriend and started to cruise the backstreets of Long Beach. He traded his bagger for a Sons of Anarchy Dyna, and is about to turn the 88-inch twin cam into a 106-inch S&S night flier. His band, the Signal Hill Billies, transformed their usual light country western twang into dark blues. What the hell did I do? We will bring you reports on his engine transformation. I could swear the all-black lowered hearse smirks at me whenever I roll into his parking lot, but we won’t go there.

I pulled up the other day to find Frank’s Mudflap Girl on a lift center stage. No sooner did I enter the shop when Eric slipped out the back. A mysterious tech sauntered out of the engine room with long gray hair. “Don’t take my picture,” he said, “and don’t mention my name in the article.”

I’ve known him a long time. He’s an experienced Bonneville racer and a multiple-tour Vietnam vet, about my age. He’s only been married once, and is still married to the same woman. “I swear,” he said, “I’ve never pulled my military issue bayonet on my wife.”

I’ve been married five times and Eric three, and he just broke up with his long-time girlfriend. Maybe the graybeard tech with his twisted grin was trying to say something.

What the hell could I say? I set the box of parts on the lift and started to blow the dust off the fresh engine. Eric gave me a new cone gasket, seal, and a Torrington cam bearing, in case the fresh engine was fitted with a poor quality INA bearing—it was. I removed the pipes. The tech removed the plugs, and we jacked up the bike. He popped the pushrod covers and broke out the bolt cutters to remove the stock pushrods without removing the rocker boxes.

“I roll the engine over so the valves are closed when I cut the pushrods,” Graybeard said, “so the valves don’t slam shut when the pushrods snap.”

Then he removed the point cover, and the crane Hi-4 ignition plate. “There needs to be a washer under the fastener holding the Crane point breaker plate,” he barked.

Unfortunately, I had installed the Crane system and breaker plate—my bad. I thought about my fifth wife. He pulled the cone cover with a rare Trock tool, since the master is no longer with us.

With a couple of JIMS magnetic, or H-D lifter tools the lifters were held out of the way while he pulled the stock cam and checked the bearing.

Sure enough, it was an INA cam bearing with about half the rollers of the high quality Torrington cam bearings.

JIMS tools makes a handy cam bearing puller, which was installed, and swiftly, perfectly yanked the stock bearing free. Eric made specific machined aluminum drivers for installing new bearings, which were carefully tapped into place. After it was installed, he reached in to make sure the bearing spun free, with no binding.

Next, he aligned the timing marks on the pinion gear and set up the new S&S breather gear.

Steel breather gears have better dimensional stability than plastic gears. Embedded particles can damage the crankcase breather gear cavity. A screen provides better protection than a slotted gear, so small particles are prevented from entering the gear cavity, where they may damage the gears and oil pump.

The S&S steel gear with welded in screen with larger diameter holes provides improved air flow/oil scavenging from the flywheel cavity. Crankcase flywheel cavity vacuum and oil scavenging are further improved by optimized breather window timing. Breather oil trap scavenging is significantly improved by increased scavenge port duration. These improvements are the result of exhaustive research using digital sampling and data acquisition equipment.

This gear was the standard size for late 1977—‘99 Harley-Davidson big twins. Breather gear kits include breather gear and steel endplay shim kit.

With the new S&S breather gear installed, he started to adjust the endplay with a .120 shim. “That’s usually the one,” he said. As it turned out, we went with .110-inch shim after he checked the fitment with a straight edge. Then he performed a similar operation with the cam to check endplay. We discovered that a .055-inch thick shim was needed in addition to the existing flat shim. He dug around and found one, and we were set to test it with another JIMS special tool.

The S&S 510V bolt-in cam works well with stock or ported heads. The improved ramp design results in low valve train noise. It’s meant for engines up to 96 inches and with compression as high as 10:1. It’s designed to pull its best results in the mid to upper rpm range, 3000 to 5000 rpm.

It was time to set the cam timing with the pinion bearing and breather gear slots. Then the mystery tech cleaned some of the case threads with a tap. “Too much Loctite,” he said. He touched all the stock ¼-20 Allens with blue Loctite and installed the cone and torqued them to 110 inch-pounds. He installed the appropriate washer in my breaker plate, and then the timing plate.

Before he removed the Crane Hi-4 ignition plate, he scribed the plate and the case so the timing would be right where I placed it when everything was put back together—that is, if I didn’t fuck it up in the beginning.

I peeled the S&S quick-adjust pushrods out of their vacuum-packed container and shortened them for ease of placement. These S&S jobs were a breeze. He checked for all the needed pushrod gaskets, and we compared the pushrod lengths to use the short ones on intake valves and the long ones for the exhaust.

“I adjust them the old school way,” he said. “I make sure one intake lifter is at the top of its cycle, and then adjust the other. Then visa-versa.” He waited 20 minutes between adjusting valves for the stock lifters to bleed down, but while he waited, we started to install the pipes. “No time to lose.” He made sure each pushrod would spin after it bled down. In each case, he took the slack out of the pushrod and then turned it out four turns or 24.5 flats. Once he tightened the pushrod lock nuts, he would take the half flat out of the adjustment.

Here’s the Quickee Pushrod Supplement from S&S: To install S&S quickee pushrods, thread the jam nut off the threads towards the ball end and screw the adjuster into the pushrod tube until the threads disengage and the pushrod can be collapsed

When installed and adjusted, S&S Quickee Pushrods must have a minimum thread engagement of .500 or half an inch (Pushrod tube to Adjuster, not including the jam nut) or severe damage to the pushrod as well as your engine may occur.

When adjustment is complete, the jam nut must have full thread engagement with the adjuster screw. If you do not have full engagement, the pushrod is not correct for the application or position.

S&S Quickee Pushrods for S&S Shovelhead and all big twin engines contain two long and two short pushrods. All Sportster model and Harley-Davidson twin Cam 88 pushrodes are the same length.

We replaced the pushrod cover clips with another JIMS tool, and I finished installing the Spitfire brake master cylinder and pedal. Once together, we turned on the gas, hit the starter and it fired right to life. Our very experienced Vietnam vet tech let her warm up, adjusted the carb and quietly returned to the engine room to work on a twin cam engine build for a customer. It’s time for my son to pick up his bike and head for a paint shop or the hills.

S&S

Bennett’s Performance

Wire Plus

JIMS

Spitfire