Bikernet/Cycle Source Sweeps Build Part 7 Sponsored by Xpress

By Robin Technologies |

Hang on. We are two weeks away from running out to Vegas for Bikefest and pulling the winner of this most magnificent custom motorcycle, specifically built for Bikernet and Cycle Source fans, readers, and subscribers. You need to sign up, if you haven’t, or come to the Cashman Center in Vegas to grab a card and sign up for the drawing. You don’t need to be on site to win. After Bikefest, the scooter will return to Kustoms Inc. near Detroit, for final tuning and break-in before being shipped to the winner.

So here’s the update in a flash, after Bonneville, and heading smack dab against a Cycle Source Deadline. “I’m way behind,” said Chris Callen, the esteemed Editor da Emperor, in Chief, in Charge, in Trouble. This year has turned into the scrambling year. We are scrambling to finish projects; builders are scrambling to finish bikes. Chris scrambles every month to finish a magazine. It’s bananas.

The bike was displayed in Sturgis at the Broken Spoke. Then it returned to Grand Ledge, Michigan, down the street from Ron Finch, for final manufacturing and paint by the master of Chop Docs, Ron Harris, but let’s finish the pieces first.

“I kill batteries no matter what I do,” Gary Maurer said as we started to discuss the battery box. “When I carefully rubber-mount the bastards, they vibrated enough to rip the battery cables to shreds.” So now he puts a small rubber lining under the battery and bolts the unit down hard with Jules-made steel battery straps. He is now using Brail and Ballistic batteries with some luck. This is where I started to learn more manufacturing processes from Gary and Jules, again.

It’s interesting. I don’t consider myself a builder, and when I work with someone with the manufacturing knowledge of the Kustoms Inc. team, I know I’m just an enthusiast, not anywhere near a pro builder. This story contains a couple of fine examples of their expertise. The battery straps are easily bent after marking the position for the bend on the top corner edge of the battery. Jules made the hand bend with a solid bar of steel, and then noted the amount of metal used in the radius and worked it into the formula for the next bend so the strap fit the battery perfectly.

“There is a mathematical formula for this process,” Gary said. “You need to add or subtract material from the next bend, but we bend one side and then adjust the other.”

I also noted how perfectly the fender edge fit the line of the tire, since most fenders do not align with the tire radius. “We often scribe the radius of the tire on the fender and cut it to match perfectly,” Gary said.

He uses thick welder ground cable stock taped to the fender to give him the proper fender clearance. “Sometimes we use chunks of busted rear drive belts,” Gary said. “Sometimes, if need be, we can double the belt, or mesh the teeth for a slightly larger space.”

They break the chain to be as close to the center of the adjustment path as possible, with the engine, primary and transmission in place. Then they adjust the chain to be bowstring tight, and then they tape the spacing material to the tire and start mounting the fender.

This Bare Knuckles fender was bobbed and channeled on both sides by Jules. She often cuts with a plasma cutter, and then works the edge with Matabo grinder with flap wheels. Bare Knuckle fenders are made with solid, thick spun steel. They are as strong as a battleship hull and easy to work with. “Our plasma was toast,” Gary said, “so she used a high-speed cut-off wheel, then the Matabo and flap wheels.

I like the exhaust system he built with D&D components and a carbon fiber muffler. I asked how he held the components accurately together for tacking. “I start generally, but not always, with the muffler in place and move forward,” Gary said. “I hold the chunks in place with three fingers and tack them.” If his weld pulls away from the joint, he adds a small ball of rod to one piece, then holds them together, and heats the ball until it flows to the other tubing piece.

Note how Jules fashioned the lower fender mount to the frame so it acted as a battery strap mount and fender mount.

Then Gary built the sissy bar by hand-bending the steel rod. He machined each chunk of bar stock for the frame rails, and drilled them ½-inch so the rail would simply insert into the welded boss. Then he drilled and tapped them for setscrews. On the top, he welded a machined bung to the bar, and a drilled and tapped the bung to the fender, so the fastener simply slips through the sissy bar tab and screws into the solid bung on the fender.

With all the components tested and brushed with flapper wheels, Ron Finch stopped by and picked up the components for the trip to Ron Harris, a third generation paint and body shop guy. “I couldn’t touch a paint gun until I could bump a fender,” Ron said of his granddad. Back in the day, bodywork was hammered and filled with brazing and lead.

“My dad called Bondo Chinese lead,” Ron said. Then he ran down the Chop Docs custom paint process. From the photos, paintwork slides along like ironing an old pair of Levis (who the hell does that anymore?), but any top-notch painter has the talents of a concert violinist. It may look easy, but there’s a refined eye and level of perfection that turns any steel surface into a perfectly smooth piece of art.

As soon as Ron Finch dropped off the components and peeled out, Ron Harris cleaned the welds with a cookie wheel, and then scuffed all the surfaces with 80-grit for a world-class bonded protective coating. Initially, paint was used solely to protect a surface. Now it protects and adds the final illustrious finish.

Then he coated all the sheet metal surfaces with a filler Bondo skin coat and block-sanded the surfaces. This is where perfection and talent come into play. I’ve been there. I couldn’t Bondo a baby moon hubcap and make it look like new. There’s an eye for sanding just the right level of Bondo to capture the perfect slick surface.

He followed the Bondo coating with a skim coat of putty to capture imperfections, and then tested his eyes with various levels of Emory paper from 80-grit, to 150, to 320, so he can minimize his primer usage.

“I’ve been working with Stage 5 Coatings for two years,” Ron said.

States with Stage 5 or Technico:

Michigan New York

Illinois Missouri

Texas Oklahoma

Wisconsin Oregon

California Arizona

Washington Georgia

Maryland Caribbean

Virginia

Ron is working with Ken Dudley on a line of Chop Docs candies. After he primed all the surfaces, he used a black spray bomb dusting to cause imperfections to surface. After any pits or surface maladies were dealt with, he water-sanded everything with 400 grit wet and dry, and then hand-sanded with 600 grit and finished off with Scotchbrite.

With the components hung in a booth, he primed them with two coats of sealer, and then hit them with the silver base coat and inner clear before taping off for the black pearl inlay. Then everything was cleared again and sanded with 600-grit.

This was Ron’s first attempt with green variegated leaf* using Mona Lisa glue to attach it to the paint surface. “It’s like a very thin, watered-down Elmer’s glue,” Ron said. “The leaf is so thin, it’s like dust in your hands.”

Once the leaf was glued into place and the area cleaned with a cotton ball or a brush, Ron hit it with another coat of inner clear, which locks the base down and leaves sort of a satin surface to adhere any art to, such as pin striping by John Harrow, who used a one-shot enamel sign paint called Kansas City Teal.

Now for the final six layers of gloss clear coats and 1500 grit wet sanding, followed by 3000 grit with water, and then buffing with polishing compound, finishing glaze, and spit shine. It’s Saturday, and by Monday, all the elements will be returned to Gary and Jules and Kustoms Inc. for final assembly. Ron volunteered to help. Unfortunately, he’s 140 miles away, but he drove out and spent all day, Sunday, helping with assembly. “It’s 80 percent there,” Ron said on his way home.

Speaking of volunteer efforts, this has been an amazing build with efforts from a variety of sources, all to create a bike we are giving away. No one made a dime off this puppy. It’s all American-made, and the whole gang pulled together to offer Bikernet and Cycle Source readers a shot at a world-class custom motorcycle—thanks. Chance of a lifetime, goddammit.

Dimensions: 5½” x 5½”

Xpress

http://mysmartcup.com/

Crazy Horse

http://www.crazyhorsemotorcycles.com/

Texas Bike Works

www.TexasBikeWorks.com

Kustoms Inc.

KustomsInc@hotmail.com

Chop Docs

www.Chopdocschoppers.com

3 Guyz

www.3Guyz.com

Accel

Accel-ignition.com

Fab Kevin

http://www.fabkevin.com/home.htm

.jpg)

Evil Engineering

www.evil-engineering.com

D&D Exhaust

http://www.danddexhaust.com/

Wire Plus

http://www.wire-plus.com/

Barnett

Barnettclutches.com

Rocking K Custom Leathers

howard.knight@montana.com

Rivera Primo

www.RiveraPrimoInc.com

Spectro Oils

www.Spectro-oils.com

Bell

www.moto@rcn.com

Metzeler Tires

www.metzelermoto.com

.jpg)

Hawg Halters

Handy Industries

www.HandyIndustries.com

Grip Ace

www.gripace.com

Biker’s Choice

www.bikerschoice.com

Aeromach

www.aeromachmfg.com

Ride Wright Wheels

www.ridewrightwheels.com

Biker Pros

www.BikerPros.com

Bare Knuckle Choppers

www.bareknucklechoppers.com

K&N

www.knfilters.com

Bikernet/Cycle Source Sweeps Build Part 5 Sponsored by Xpress

By Robin Technologies |

I’ve never had so much fun building a bike, and it’s not for me. This one-off custom, art object, long-run bobber, chopper, will be awarded to either a Cycles Source subscriber or a Bandit’s Cantina subscriber on Bikernet.com. There’s always a growing buzz around building any bike. The vibe could be associated to the deadline, like the run to Sturgis, or a Bonneville land speed record effort, or for many shops, it’s a particular customer’s dream project. In this case, Gary Maurer, and Jules, from Kustoms Inc., created the aura of the build.

Okay, it started with Prince Najar and spread to the Crazy Horse Engine Company, and Jason from Texas Frame Works. I can feel it anytime I speak with Gary at Kustoms Inc., or John White from Crazy Horse. John runs a massive construction equipment company, but when we discuss his bottle cap engines, he glows and gets pumped. Gary and Jules built hotrods for years. Much of their fabrication codes come from building record-breaking dragster. They still hold a 6.51 second record at 209 mph with a Larry Morgan 500 cubic- inch pro stock engine.

Kustoms Inc. is a talented team capable of almost anything mechanical, but it’s their level of passion for the craft and every element of the build that’s captivating. Take for instance, mounting these classic 3.5 gallon Biker’s Choice re-popped tanks.

During the initial, design Gary planned the bike around classic H-D fatbobs, and bent the backbone of the frame to match the radius of the tank tops. “It’s basically a 12mm or ½-inch roll to match these tanks,” Gary said. “The tanks are almost flat at one point, but we work around them.”

With a ring roller/radius machine containing two dies on the bottom and one on top, he pushed the 1 3/4-inch tubing down 1mm at a time, forming the radius. He rolled the backbone slightly and then compared it to the tank, and rolled it some more. If his tubing length was long enough, it would form a 20-foot diameter circle.

He selected 3.5-gallon tanks since, the exposed frame backbone spreads the tanks and gives them the appearance of larger 5-gallon tanks. “Five gallon tanks would be too large,” Gary said. “During the mounting process, we level out the 3.5-gallon gas caps, eliminating the droopy look, so they appear similar to 5-gallon tanks when finished.”

Gary constantly keeps ride-ability in mind; consequently, he vents his tanks with a tee between the tanks, which he runs near the neck to be above the tanks. “The caps don’t always do the trick,” Gary said, “and once in a while can cause a vapor-lock.”

Then Julie went to work fabricating cosmetic caps to cover the indents in the front of the tanks, the speedo portion of the tank, and the stern indents. Each chunk of metal is bent 90 degrees in the metal break. Then she uses another tool to stretch and shrink each piece until it fits the contour of the tanks perfectly.

Gary started to chuckle was we talked about the classic tanks. “I’ve never run across a set of fatbobs that matched. One is always slightly longer than the other.” Julie attempted to make up for the difference when she formed the caps at the rear of the tanks.

With each cosmetic cap fabbed and tacked into place, Gary goes to work mounting the tanks using his tab kit, duct tape and wooden slivers. “If we TIG-welded and ground the caps you couldn’t tell where they were from photographs.” First he welded two front/upper mounting bungs to the frame, and then positioned the tanks with duct tape and wood wedges to fine-tune positioning. With the tanks in a perfect location, Gary tack welded the ¼-inch thick Kustoms Inc. tab kit elements in place, and then moved to the lower front tabs.

“I usually afford a 3/16-inch gap when it comes to rubber mounting components,” Gary said. “Since the tanks don’t generally match, we use this bottom mount to correct any oddball positioning. The J-tab might not be perfectly centered in the frame, but the tanks will be positioned exactly right.”

Here’s a quick indication of Gary’s involvement in this project. He has loaded this puppy and displayed it at seven shows around the country so far, next being Mountainfest in West Virginia, July 28, then off to Sturgis. The bike can be seen at the Chop-in Block at the Broken Spoke Campground all week. Come out and sign up to win. Also the bike will be displayed at the Cycle Source Chopper Show on Friday, August 10th. Okay, so this bottom J-hook mounting arm also acts to spread the tanks slightly, so the caps stop drooping.

The final tabs run off the back of the tanks and replace the stock tabs. “I make our tabs as heavy as I can,” Gary said. “I would much rather replace a five-buck rubber insert every five years, than a $1,000 paint job and a cheap tab.”

The final bike building code of the west lesson blossomed from Gary’s rule regarding mounting anything. “I never force anything,” Gary said. “Every part fastener should finger-spin into place and set as if in a natural state, no stress.”

Next issue, Gary will modify a Bare Knuckles rear fender, and we will see the spinning process. Then Julie will mount her handmade oil tank, right after Gary modifies Jason’s frame for proper spacing.

In the meantime, make sure to put your info into the hat for a definite chance to win this one-off, hand-built custom motorcycle by some of the masters in the industry. This is an opportunity like no other. The award ceremony takes place this summer at Las Vegas Bikefest, and no, you don’t need to be in Vegas to receive your prize. Just step up and subscribe to Cycle Source, or Bandit’s Cantina on Bikernet. You help support our efforts and receive a shot at a world-class motorcycle in the process.

–Bandit

Xpress

http://mysmartcup.com/

Crazy Horse

http://www.crazyhorsemotorcycles.com/

Texas Bike Works

www.TexasBikeWorks.com

Kustoms Inc.

KustomsInc@hotmail.com

Chop Docs

www.Chopdocschoppers.com

3 Guyz

www.3Guyz.com

Accel

Accel-ignition.com

Fab Kevin

http://www.fabkevin.com/home.htm

.jpg)

Evil Engineering

www.evil-engineering.com

D&D Exhaust

http://www.danddexhaust.com/

Wire Plus

http://www.wire-plus.com/

Barnett

Barnettclutches.com

Rocking K Custom Leathers

howard.knight@montana.com

Rivera Primo

www.RiveraPrimoInc.com

Spectro Oils

www.Spectro-oils.com

Bell

www.moto@rcn.com

Metzeler Tires

www.metzelermoto.com

.jpg)

Hawg Halters

Handy Industries

www.HandyIndustries.com

Grip Ace

www.gripace.com

Biker’s Choice

www.bikerschoice.com

Aeromach

www.aeromachmfg.com

Ride Wright Wheels

www.ridewrightwheels.com

Biker Pros

Bare Knuckle Choppers

www.bareknucklechoppers.com

Mudflap Girl FXRs, part 11: The First Road Test

By Bandit |

Mudflap Girl, chapter 10: http://www.bikernet.com/pages/Mudflap_Girl_FXRs_Part_10_Suspension_Tuning_and_Le_Pera_Seat.aspx

I can’t make it to Sturgis this year. We are focused Bonneville builds, like mad starving dogs, and the two events are only separated by two weeks. Ray is tuning and I still don’t have an engine, but we’ll cover that later. The engine could be running today, in Richmond, Virginia, at Departure Bike Works.

Okay, so what’s a poor bastard to do, when he planned to make the run to the Badlands with his brother Hamsters? They ride out from the West Coast every year. Some of the members, including Arlen Ness are in their 70s and riding custom Victory bikes. Some rode from Spearfish, South Dakota, out to Mammoth Lakes, California, to ride back to the Badlands with their brothers. So, what’s the least I could do? Meet them at their first stop in Mammoth, just east of Yosemite?

The good doctor has owned several motorcycles, including a 1934 VL I helped get running, but one motorcycle stuck with him, a 1989 FLH. He had clocked over 200,000 miles when he decided to rebuild it. Bennett’s Performance handled the semi-stock Harley engine (the rebuild was covered on Bikernet). With a couple of thousand miles on his rebuild, and 50 on mine, (another 80-inch semi-stock Harley engine, assembled by S&S, with headwork by Branch O’Keefe), we rolled out of Los Angeles.

About 15 million folks know rolling out of Los Angeles is the biggest challenge to any weekend excursion to someplace less congested. It’s amazing, like no-man’s land at the front of any war zone. Just try to slip out of Los Angeles on a Friday. Try to peel by noon or before. If you don’t you could be faced with serious bumper-to-bumper malady, or a lane-splitting conundrum. We recently published a report about splitting lanes and the benefits. They actually made a case for increased safety in areas supporting lane-splitting.

I’ll make one case for the freedom to split lanes, maybe two. Well actually, the published study pointed out the benefits of keeping motorcycles moving during high-congestion back-ups. My point included any rider’s sense of alertness. When splitting lanes the rider’s acute awareness is on high alert. Even while putting past a myriad of parked cars, a brother never knows what could blink, so his senses are hot wired. He or she is aware of anything that moves, from a slight wheel shift, to a nod, or a turned head.

So, I split lanes as soon as I hit the 405 freeway, off the 110, the oldest freeway in the US. It runs directly into the heart of Los Angeles, downtown, from my digs in the Port of Los Angeles. As I pulled out of Wilmington, two concerns stirred my humble sense of motorcycling comfort. First, I discovered my rear chain smacking the Spitfire hand made oil tank. There was always a bothersome noise bugging me, and I finally discovered the treacherous origin, the rear left corner of the FXR-styled, rubber-mounted oil bag.

Fortunately, the Spitfire team had welded a threaded bung into the corner, and a tab off the frame. I ran across the problem during assembly and removed the tab for more clearance, but evidently not enough. So the night before the run, I removed the chain, cleaned the threads with a tap, and made a countersunk Teflon bumper to protect the tank, but would it last? Or would the chain disintegrate my protective barrier, cut a hole in my oil tank in the middle of the Mojave Desert, dump all my oil onto the highway, seize up the engine, and leave me to be tarantula bait, after I baked under the 107-degree blistering desert sun?

I also made one final adjustment to my Wire Plus speedometer sensor stuffed into the JIMS Screamin’ Eagle over-drive 6-speed transmission. I had tried everything. I was at a strange juncture. It’s been so long not working, if it worked I would have been shocked. As I pulled away from the headquarters, I wasn’t disappointed. It still didn’t work. Now, I have another idea. I didn’t connect the wire from the sensor to the speedo wire directly, but to a connection board. Maybe a direct connection would be the trick.

Somewhere in the sizzling desert, with the afternoon sun baking my feeble skull, the notion of this road test article was spawned. The Mudflap Girl FXR contained only 50 break-in miles so far; this 700-mile jaunt would be the iron test. I had followed the Eddie Trotter break-in regime, almost to the tee. With each longer and longer ride, I returned to the headquarters to make corrections, repairs, and adjustments. It was time for the acid test, a long road into one of the hottest regions in Central California, a total round trip of perhaps 700 miles in 2.5 days. That’s a big deal for this old guy.

There I was, splitting lanes across the LA airport toward Santa Monica and the good doctor’s office, where he was leaning over his knockout secretary and adjusting a tall tattooed redhead. Tough job. Sticking around his office near the coast, with a bottle of something, would’ve made my weekend.

Oh, one more concern disturbed my peace of mind. I started to write peach. I was still with the girls in the office. I hand-made the two mounts holding the single RockShox to the girder. My mind whirled with 80mph impact, a bottoming out shock, and the stress on the mounts. Would they last or toss me into the fast lane of a crowded Los Angeles freeway? Ah, for the days when we would build a bike, smoke a joint, down a shot of whiskey and ride some half-wired together chopper across town at breakneck speeds to her house. Hell, we felt so good, it didn’t matter if we made it our not.

While parked at the good doctor’s office, I inspected my Teflon pad. It was sliced severely, in just 40 miles, but the next 40 or 100 would finalize the experiment. My shock mounts hung tough, but what about the next 100 miles? We gassed up and peeled out onto a crammed 10 Santa Monica freeway. Splitting lanes and dodging merging traffic we weaved onto the 405 Freeway. It peels over the notorious Sepulveda Pass, into the San Fernando Valley, and beyond toward the 5 Golden State, high-speed direct link from Los Angeles to the bay area and San Francisco.

We just needed to cut across the 101, to the 5 for a five-mile stretch, and then off on the 14 toward the Mojave mile airport landing strip and land speed trials location. I felt every bump and groove in the crappy road as I leaned into the fast lane and poured the coals to this 80-inch beast. It ran sweet. I set up the dual-fire, Compu-Fire ignition according to instructions, and installed the Trock modified CV carb, but never adjusted any aspect of it, except the idle.

The week before we peeled out I rode to Bennett’s Performance and Eric popped the cap off the air fuel adjustment behind the float bowl, and adjusted it—it was too lean. Trock removed the cap, so the adjustment screw was operational. I rode the bike, noticed an intermittent cough, and called Eric. He recommended backing out the needle one-quarter turn. She seemed happy, and in Mojave we refueled and checked our mileage against Christian’s trip meter. We had covered 90 miles and I reloaded with 1.82 gallons for 49.45 mpg. It pulled well in any gear, even in sixth gear. The JIMS Screamin’ Eagle Overdrive transmission shifted like butter and never missed finding neutral. I geared it slightly high for a 6-speed with a 23-tooth trans sprocket and 51 on the rear wheel.

So far, we flew along big wide freeways through the Soledad Pass, Palmdale, Lancaster, and then into Rosamond. At over 90 degrees, the freeway started to die and turn into a two-laner along-side the Pacific Crest National Trail leading into the Sequoia National Forest. It looked sorta bleak and hot to me, as I pondered the welds that held my chopped Spitfire bars together. So far, the riding position was a dream. My legs were stretched out nicely. I could move around on the very comfortable gel-impregnated Saddlemen seat with the spine relaxing channel, and just a touch of lumbar support. The bike handled well, as I adjusted to the long bike vibe.

Another rambling rural 50 miles in the desert with only rolling hills in the distance, and the 14 Highway disappeared to be replaced with the well-kept Highway 395 in Indian Wells Valley. We passed more deserted truck stops, than active ones. They were extreme sun-dried out buildings. Chipped paint was sandblasted by desert winds, and busted windows gave the dilapidated structures, gradually turning to dust a war zone appearance. I set the bike up to be a chopper for the long road, with rubber H-D pegs, old styled thick rubber Knucklehead grips, and Custom Cycle Engineering rubber-mounted traditional dogbone risers. Since the drive train was rubber-mounted, it all worked to minimize vibration.

We followed one billboard to an old gas station turned into jerky sales headquarters. It bragged “Good jerky.” It was actually so-so, and small packages were priced at nine clams. I wanted to support their sticker-scattered cause. The smiling Hispanic broad behind the counter gave me the okay to plant a Bikernet sticker on the building, yet I couldn’t cough up nine bucks, plus tax for a bag of so-so jerky. We peeled out.

Just a handful of small towns peppered the highway with reduced speed signs, some as slow as 25 mph, perhaps a fund-raising effort. We rolled into Lone Pine and the Dow Hotel, which was packed with tourists and bikers heading to Sturgis. The Dow, built in 1923, was specifically constructed to house movie crews, since a large number of westerns were shot in the region. What a roll of the dice, but it paid off. We topped off and compared notes this time. We had sliced through 111 miles and I took 2.3 gallons, for 48.3 mpg. The doctor grabbed more fuel between stops, so he crossed 38 miles and took 1.2 gallons for 31.6 mpg. He was disappointed, and we discussed options for the future.

The good doctor noticed some drops of oil on the pavement next to my bike. My oil cap isn’t correct for the screw-in bag bung, so I found a press-in rubber cap, with a small dipstick. It worked, but loosely, and a small amount of oil seeped onto the roof of the Spirfire steel oil bag, then some trickled down the right side, onto the frame and dripped onto the pavement. I pressed the oil cap deeper into place and check the oil level, and then it dawned on me. I noticed a softening in my rear GMA brake action. That was the cause.

[page break]

I checked the Teflon pad, and it didn’t indicate any more chain damage, plus the tank was well clear of the carved edge. It appeared very secure, and my shock mount held fast. Vibration was minimal, and at every stop, folks confronted me about the Mudflap girl bike, the traditional chopper appearance, and almost every onlooker said, “Is it a rigid?”

The next morning, we faced just 99 miles for our meeting with the evil Hamsters at the Westin lodge in the heart of Mammoth lakes. The roads were perfect and our 80-inch Evos purred as the elevation increased from sea level to 4000 feet, and we were expecting another 4000 thousand and more pine trees as we cut a dusty trail toward the Sierra Nevada Mountain Range, just east of Yosemite. We stopped in picturesque Bishop for breakfast, but the two hot spots were jammed. We strolled into Whiskey Junction without a problem, then rode the remaining 40 miles to the Mammoth cut-off. I was expecting winding, twisting mountain roads into the mountain/sky resort community, but it was virtually a straight shot. My memory reminded me of a similar stop the year I hit a deer inWyoming.

We didn’t pop for the high-dollar rooms, but stayed down the street at the Sierra Motel, where the doctor pointed out a concern with his front wheel. We rode up the street to hang with the Hamsters as they rolled in as early as noon. Some rode in from Spearfish, but the Bay Area contingent, including Arlen Ness chose to fight traffic in slow lanes through Yosemite National Park. They weren’t scheduled to arrive until the early evening, so we returned to our digs to take a look at his front wheel. Under the backdoor hotel overhang, we found a massive cinder block, jacked up his FLH and removed the front axle. One of the bearings demonstrated serious damage and we attempted to remove it with the help of the Hawaiian biker handyman.

We easily had enough tools between my Bandit’s bedroll and the doctor’s tool bag. Concern grew as we discussed our issue with other riders, and Ted Sands, from Performance Machine. “Did you powder coat the wheel?” Christian scored a couple of late model Twin Cam, 1-inch axle mag wheels, powder coated them, and replaced the bearings with ¾-inch axle jobs, but there was some question about the internal spacer. The spacer needed to be solid against the inside bearing race, and that didn’t seem to be the case. The left bearing demonstrated serious wear. We started to make calls.

The Mudflap Girl bike handled the roads to Mammoth extremely well, although we are hoping to step up and buy another RockShox with at least 2-inches of play and a 250-pound rated spring for testing in the future. I’m sure with the correct resources, we can make this girder ride like a Cadillac. I ran into one problem with the Mudflap girl. The left stock H-D foot peg with massive rubber padding for comfort, wanted to slip off the stem and depart. I thought this bastard wouldn’t budge, but I continually fought it.

We called for local bikes shops, but it was Saturday night and resources were limited. Christian made a run on my FXR to an auto parts and bought a jug of bearing grease, a spray can for chain-styled foam lube, and a small container of Buffalo-snot glue for my peg. I actually needed rubber cement, but gave it a shot.

“The FXR Chopper is one great looking scooter, with just the right stance to have attitude, without being obnoxious,” said the Doctor. “Everyone twists their neck when she goes by.

We operated as best we could on the doctor’s wheel but could not remove the bearing to correct the inner spacer problem. We packed that bastard full of grease and called for a U-Haul truck rental in Bishop for the next morning. The final question: Could, would, should the good doctor risk riding his Bessie down the hill? We confirmed with U-Haul; the regional office would open at 7:00 a.m. The Bishop franchise opened at 8:00 a.m., and a 14- foot box truck was available with a ramp. We would need to score a batch of tie-downs.

We returned to the Westin to hang with our brothers, Buckshot, a Bikernet and Thunder Press contributor, and Marilyn Stemp, the editor of Iron Works. That’s when Ted Sands told us about the drawbacks of powder-coating the interior of late model hubs and the impact on bearing spacers—bad news. I rode the FLH, and it rattled like marbles in an empty tin can, but I didn’t sense any grinding in the bearings. I didn’t want to make a recommendation. This had to be his call. Then I mentioned the 40-mile distance to Bishop. He was thinking 100 miles to Lone Pine.

By the way, we gassed in Mammoth for another 98 mile run. My bike was feeling the pain of reduced oxygen at 8,000 feet, and the night would drop to 41 degrees, but she still ran well. I struggled to squeeze the nozzle into my tank and loaded it with 2.5 gallons (39.2 mpg), and the doctor refueled with 3.2 gallons (30 mpg). He will look into a jetting change for his S&S carb.

As we hit the hay, the doctor decided to attempt the slow ride to Bishop. We set the alarm for 6:30 and tried to sleep.

The weather was amazing, just a tad cool in the morning as the sun slipped between pine needles to warm the streets. We packed and rolled down the hill to the first coffee shop. We were gassed and ready for the 40-mile delicate, risky ride to Bishop, a town of 5,000 along 395 just below Mount Whitney, the highest mountain in the continental United States. We were so focused on surviving the Bishop run, we didn’t think about the cool breeze, my wandering peg rubber, or any distraction. I’m sure Christian was as tense as an over-tightened drive chain as we rolled serenely down the mountainside onto 395 south at 45 mph.

“Going 40 miles down the hill towards Bishop was a bit nerve wrecking, since the bearings were grinding and clackering like marbles in a bag being tossed on the ground!” Said the doctor.

The good doctor rode almost 20 miles, his hands, like vice-grips on his bars waiting for the bearings to scream and spit from their housing. The hefty front mag would wobble, then lock against the twin Performance Machine 4-piston front brakes and scream for relief, maybe locking up and tossing the doctor and his gear in the weeds. I asked him to ride on the right for easy access off the road, just in case.

“But after about 20 miles the sounds and noises started to be less and less,” said the doctor. “Once we got to Bishop it had subsided 80%!!!!!”

We arrived right on time, and spotted a women in the U-Haul yard. “They don’t open until 11:00.” Her husband arrived and confirmed the bad news. Disillusioned, we rumbled into town for a hearty breakfast at Jack’s and made a number of phone calls. If we could make it to Mojave, we could find another U-Haul, but then we would only be 100 miles from home. The Doctor could ask his girl to meet us there with a trailer. He called U-Haul, bitched and sought alternatives. None were forthcoming.

We said, “Fuck it,” and kept rolling. With each 50 miles, his confidence grew, but we remained at a mild pace of 60 mph, them 65. I finally got fed up with my spinning peg rubber and pulled off the side of the road and strapped it down with tie-wraps, pulling them damn tight.

“Do you want to cinch them down with a pair of pliers?” said the good doctor.

“Nah,” I responded. “We’re good to go.”

Yeah right. The sonuvabitch still squirmed and tried to escape. At the final refueling stop in Mojave, I broke out the pliers and pulled those tie-wraps as hard as I could. The bastard never moved again.

The doctor, comfortable with his FLH, resigned himself to flying into LA by himself. I would cut off at the 210 and dodge the rough, jagged, concrete 405, heading directly into one of the most congested intersections and construction zones in Los Angeles, the 101 junction, over the Sepulveda Pass to the 10 Santa Monica interchange. I could fly into the city on the foothill freeway against the San Gabriel Mountains into Glendale, cut south on the Glendale freeway for just 10 miles and pick up the 5 for one mile before I jumped onto the 110 south directly to my door through downtown Los Angeles.

As I peeled off the 5 at the 210, Christian gave me a final thumbs up and rolled into congestion for just another couple of miles, then cut off at the 405. It was just about 3:00, the bewitching hour, before a city of half-drunk yahoos, talking on cell phones and playing grab-ass with their girlfriends, headed home from barbecues, weekend camping beer-soaked outings, cantinas, bars, ballgames, you name it. This is the most notorious crew of inexperienced drivers, on unfamiliar freeways, buzzed, and distracted, heading home after too much fun. This group of millions, in tin overseas boxes and SUVs, with stereos blasting, is in contrast to commuter traffic, made up of professional, daily migrants, who know every inch of their incessant trips back and forth to work.

Both Christian and I have ridden LA freeways for over 35 years. We both rolled into our respective digs within 20 minutes of each other and checked in. Within an hour and after my first Jack on the rocks, I wrote some compliments and foreword thinking thoughts to Paul Cavallo, the Spitfire master, and he immediately responded:

“Hey brother, good to hear from you. Glad you had a great ride,” Paul wrote. “I have you covered on the oil cap. I just finished up a re-design on the girder trees that eliminates the shoulder bolts. I will update yours to the new gear.

“Bill Dodge rode his out from Kentucky for Born Free, and loved the ride, but after a 5,600 mile round trip, those little thrust washers wore thin. I doubled the strength of all of the pivot components, and machined pivot pins into the trees, and cross bars. I even designed a retro kit for all of the existing front ends.”

We discussed RockShox with increased travel, and I also mention raked trees for better cornering. The more you rake a bike, the more it wants to go straight, which hinders cornering. Bikers generally love to corner, and I discovered, with my blue flame that even a chopper can corner with adjusted frame geometry.

“When I update your front end, I will give you 3, and 6-degree links for it,” said Paul in his response. “The girder is so easy to change the rake on.”

There you have it. The first 700-mile distance test of our Mudflap Girl FXR. Scooter Tramp Scotty is right on: Evos Rule and Choppers never die.

Spitfire

D&D Exhaust

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Progressive Suspension

ACORN NUTS MEET THE MUDFLAP GIRL

By Robin Technologies |

|

||

Road King 8/8/03

By Robin Technologies |

There’s nothing like a run to nowhere. No plans, no dates, no deadlines and no formula, we just rode in the sweltering heat like two abused dogs searching for new owners. After a couple of beers, if someone asked, “why?” the cryptic answer would contain: Just to get out of town, to test the new H-D Twin Cam oil cooler, against an ’89 Evo, to see the Hamster gang on their way to Sturgis, to roadtest a new pair of denims, to have my bike blessed by a Catholic Cardinal and finally to avoid the rain.

The famous comforting Gusset in the Diamond Gusset jeans.

Granted some of this scattered reasoning was whacked. It’s summer, why would it rain? Dr. Hamster and I have ridden on perfectly clear days to Arizona, a fuckin’ desert, and it rained on us. Not a misty sprinkle that relieved the heat, but a goddamn downpour that had us standing knee deep in gas stations attempting to refuel.

High dollar chain wallet for road protection. It was given to me at the LA Calendar show by a blonde knockout. She handed out free wallets to anyone who would stare at her tits or her sponsor’s truck, Schapiro & Leventhal, The Motorcycle Attorneys.

This time we got the hell out of Dodge in the middle of the day, under scorching rays. The day before I tore into the King, changed all the fluids and installed a new 1999 and later oil cooler for touring models. Several readers wrote concerning cooling problems with Twin Cams, and I did some research. According to Clyde Fessler the Twin Cam was destined to be a fluid cooled motor, due to the excessive heat that the factory design crew couldn’t eliminate, until Jim Fueling stepped in, at the last minute. Jim tested larger exhaust valves to remove the hot exhaust gasses fast and efficiently. Apparently, his input saved the Twin Cam project. It’s not unheard of to see a Twin Cam running through town with oil heated to over 240 degrees, whereas an Evo will trip through the same crowded streets cooking the oil only to 130 degrees. That’s significant. The installation is destined for publication in American Rider and on Bikernet in the near future.

After washing, the Gusset jeans didn’t shrink. They had the length I needed.

As the week closed, and I loaded my shit for the run, a package arrived from a new Bikernet advertiser, Diamond Gusset Jeans. Here’s a confession: I’m close to 6 foot 5 inches and have a problem finding denims that fit and have the length for cowboy boots on bikes. I discovered that my 36-inch-inseam pants were riding high on boot shanks. Another tall partner recommended 38-inch inseams. I started looking. The only pair I hunted down were special ordered from Levis. There was a catch. They were unwashed 501s. When I washed them, they shrunk up to 36-length. Gusset came through with britches built loose for a biker and long enough for a tall bastard. I decided a road test was in order.

No button-fly on the Diamond Gusset jeans.

We traveled light, threw a couple of T-shirts in a bag, with some sunscreen and night glasses, and we hit the road with a digital camera. After only 31 miles, I met Dr. Hamster in Santa Monica and checked the oil temperature. It indicated 213 degrees and my ambient temp gauge told me it was 90 degrees on the coast at 11:00 a.m. We rolled onto the 405 freeway, to the 118 East, to Glen Oaks where we spun off to have our bikes blessed at a custom car gathering near the Hansen Dam. It’s an old school, new kid gathering of lowriders, hot rodders and bikers. It was located in a hot open park, in Pacoima, packed with metal flake, primer, babes, chrome and flames. We had scrambled through another 52 miles and the King was sporting 222 degrees in the 95 degree air temp. The jeans were still comfortable in the blistering sun. I wasn’t forced to pull on the legs for relief, as I sat in the King saddle.

Restored 1958 BMW

We dodged security and fluorescent cones to park with the show cars next to a 1958 restored R27 BMW single. A classic machine. A girl wearing a black quilted welder’s cap was lying in the grass. “I’ve had it seven years,” she said behind dark sunglasses, “but it took me a year to get it rolling.”

Dr. Hamster, riding partner and therapist.

We were impressed by the tattooed broads dressed like ’50s rod chicks with bleached blond hair in curls, checkered tops pressed against store bought tits and ruby red lips. An artist Sara Ray caught the action on canvas. She should go places.

Sara Ray art, (562) 223-0967.

I ran into a couple of riders I had featured in past issues of ER and one displayed his super sanitary, teal Panhead. I told him it deserved a feature. The truck-built hot rod by Ian Rousseau, was unlike anything I had ever seen. But the sizzling summer sun drove us back into our saddles and down the road. It doesn’t matter what the temp gauge says, at 100 mph we’re cool.

Industrial hot rod built by Ian.

We jammed onto the 210 freeway heading toward Pasadena when the traffic locked up. Downtown Pasadena and Sierra Madre are known for their restaurants and Sierra Madre Motorcycles.

Gusset jeans is Sierra Madre restaurant. Note the handmade Bikernet belt buckle.

We jumped off the freeway for chow at the Pepper Tree in the quaint Sierra Madre village. After refueling we were hell bent for Barstow on the 15, the main artery to Las Vegas. It’s a grizzly stretch of desert asphalt aimed at the border of Nevada and California.

We rode from the 210 to the 57 south, to the 10 east, to the 15 north, where we discovered that the 210 connected to 15 directly. We sliced through traffic jams in Monteclair, Ontario and Rancho Cucamonga. These goddamn towns are spreading across the desert toward Vegas like Locust on a ripe crop of corn. The traffic is stifling in Los Angeles, but there are times, when the revs of your motor match the rhythm of your heart beat, and you dance with the devil in lane number one. When the fast lane lagged we dropped, like fighter pilots, across four lanes of whizzing compact bumblebees, into the slow lane, between off ramps. We down-shifted a gear and gunned our motors, until we screamed past the slugs, then peeled back, through the vast expanse of lanes, to our home in Fastville. Dr. Hamster, aboard his ghost flamed ’89, blacked out FLT, with over 200,000 miles on the clock, slipped traffic like a wire through pepper cheese.

Freeways expand annually, but the traffic spreads with over-population, like ants in a sugar bowl. There’s no catching the growth. At one time various freeway sported motley personalities. The 15 was a truckers’ freeway, but now it’s Las Vegas central, fighting with 18-wheelers, for asphalt space, as the highway narrows peeling between desolate Day Canyon and the desert town of Fontana leading into the San Bernadino National Forest. For the first time we smelled open highway mixed with diesel fumes and blistering heat. The King held to the road tight as we piled on the high-octane coals and roamed into the hills toward Hesperia, the home of Atlas Frames.

“I won’t do much over 90,” the good Doctor told me at a gas stop. “This thing quivers too much.” We discussed Wil’s invention, the True-Track. “Yeah, I talked to Wil,” Chris grimaced, “he doesn’t manufacture them for early Evos.”

Mountain Gusset jeans test.

While flying along the freeway, just slightly below his limit, I watched the ass of his FLT shake like a plump girl dancing to Chubby Checker. The King held fast except on one sprawling stretch of cement freeway, carved with a cheese grater device, to form rain grooves. Occasionally the grooves snagged my Avons. They were no- more than hiccups on an otherwise perfect ride. We could smell Barstow, as if a camel could sniff sand, 60 miles east, as we cut through the Cajon Pass at 4260 feet. We made light of the next 40 minutes peeling through open miles, darting from one car or 18-wheeler to the next, like a kid playing pinball with Toyotas. Except our rule book called for going around as many lumbering vehicles as possible without touching any.

Barstow is a town millions travel through, yet never see. Freeways have that adverse effect on society. They slice through lovely seaside communities, but the travelers never experience the water’s edge. I’ve skidded through Barstow too many time to mention, but this time we rolled off the second “Business exit”. There were four. We should have stayed on the freeway and hit Daggot, Baker or Ludlow. Take it back, they’re all two-pony towns with one gas station. At least Barstow accommodates five restaurants, a major supermarket, and another succulent item, I’ll mention later.

It’s a dusty berg, of one main street and a myriad of motels, two Holiday Inns (one at each end of town) and a couple of Route 66 joints. Two main Mexican restaurants called to us, singing Maria’s Cantina ballad, but we were on a mission to hook up with 50 Hamsters riding across the country to Sturgis. The last time I split with them through 1,800 miles to the badlands, was two years ago, when I head-butted a deer, on a Buell, in Wyoming.

The hotel parking lot was jammed with customs and dressers. We unpacked and asked the host behind the counter for a room. “We have one, but it’s smoking,” the young guy wearing an flowered Hawaiian shirt said.

“When it stops smoking, we’ll take it,” I said. The Gusset jeans survived their first putt. The bike was peaking at 224 degrees in the 97 temperature and Chris’s Betsy held to 165 degrees. It was time for a beer.

It was good to see the bros, and even better to see Jennifer, the bartender. She sported a recent boob job and wore a top she should wear while cleaning her kitchen on a hot day. In her late twenties her boobs pushed against that spaghetti strapped, shear fabric like… Well, you know. They popped over the top, pressed out the sides and protruded just above her thin waist. Her budding nipples talked more than she did. The first thing that came to mind were the ominous words Sin Wu said to me as I pulled the King into the street, “Do me a favor. Don’t hook up with a girl in Barstow and make another life long friend.”

I could see friendship, in the making, each time Jennifer bent over the deep sink to clean a glass, those luscious soft mounds whispering endless tenderness to me.

View from Ramada window.

Shifting gears, back outside Barry Cooney pointed out his latest creation that’s scheduled for the cover of ER in the near future. It was a S&S, 120 inches of chopped monster surrounded by Ness frame, wheels, controls, etc. Barry has an eye. Mr. Lucky was one fine looking motorcycle. I apologize for not taking a group shot of the yellow shirted rodents. I was consumed with hanging out with some longtime pals.

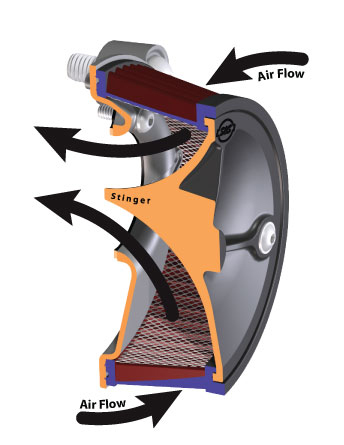

Here’s a tip, not a tit, yet. Barry’s bike sports an S&S shorty and it was gagging at mid range. He tried everything to remedy the problem with no luck. Even S&S volunteered a carb replacement. He finally hauled the bike to a renowned motor man. After research, he discovered that the big engine was sucking the float bowl dry through the vent. He drilled a direct vent to the outside of the carb and welded up the internal vent. The bike hauls ass.

Speaking of ass, we scarfed enchiladas at a local Mexican restaurant and returned to Molly’s bar. I was wearing a DragonFly Hawaiian marvel that caught Jennifer’s eye. “I see you cleaned up, big boy,” She said with a smile that would melt a man, like a rose bud torch tip. My Diamond Gusset jeans handled the Jack Daniels with aplomb, but I avoided making a new friend. After five marriages, I’ve learned something. Not sure what the hell it is, but I blinked and let the opportunity pass. She had soft blue eyes and a smile that beckoned. A playfulness danced on her lips.

I finished my Jack and said goodnight as the conversation lingered. It was good to hang with the guys and catch up.

The Hamsters were scheduled to ride to Williams, Arizona the next morning, a mere 180 miles down the road. They had no choice, but to peel along the 40 interstate into the brittle Arizona underbrush. We had cut through a taste over 200 miles to reach Tarantula Tomb Barstow. Williams and another freeway didn’t call to us. We wanted two-lane highways and twisties.

Train racked sunrise in Barstow.

I was up at 6:00 a.m., since two sets of train tracks border the swimming pool out back, and our room faced the pool. Every 15 minutes trains packed with 40-foot truck containers rumbled past hell bent for Los Angeles, like machine-gun fire in the ghetto. I opened the window once and the crackling noise of a passing train blew me over my bed. But the sunrise was spectacular over the barren arroyo in the distance.

I dusted off my HA leather vest, donned a Crime Inc. T-shirt, and the good doctor and I hit the road before the rodents climbed out from under their sawdust covers. Small roads were the order of the day. The winding choices throughout the southern half of California were many: Big Bear, Ortega Highway, Oceanside, Escondido, San Clemente. We jumped desolate 247 running out of Barstow for the hills where we had breakfast in the Lucerne Valley. Check the signs around the restaurant at the corner of 18 and 247 Highways. It was nearing 75 degrees and the King’s oil was relaxing at 202 degrees in comparison to the Doctor’s dresser at 150 degrees.

We began a hill and mountain hopping ride on the 18, to the 38 into Yucipa, then stopped in Redlands for a beer. It was cresting 90 degrees, but the King’s oil had cooled to 191 degrees and the blacked out FLT was flying at 130 degrees. At that point the Doctor revealed that he was catching the 24 hour Mung. At 90 degrees under dazzling, Southern California sun shine, he had the chills.

We were in Redlands when I backed away from him at the Hotel California and dashed toward my ride. We caught a the 10 Freeway to the 91 and onto the 215 into Perris where we jumped off on the 74 by shear luck and scrambled over the Highway Patrol-encrusted Ortega Highway. They were behind every pine tree strewn corner. Bikers waved us to slow down at each bend.

We dipped and weaved into San Juan Capistrano on empty tanks, refueled, grabbed a bite to eat, jumped the 405 north to Los Angeles and home. I rolled into breezy San Pedro in the afternoon with 430 miles on my trip gauge, for the weekend, and 215 degrees on the digital oil temp gauge. Every rider we ran across praised the King and discussed finding one. The bike ran flawlessly, and the Diamond Gusset jeans survived the heat, the sand and the hot wind. I would estimate that the oil temps were down 20 degrees, we avoided rain and goddamnit, got to party with the bros.

–Bandit

Road King 4/18/03 Part II

By Robin Technologies |

The nacelle came off with the four dome nuts that hold the detachable windshield, but when we looked at the chunks of chromed steel we came face to face with the rubber mounted brass fasteners that hold in the headlight. With a little twisting and tugging they came away from the case.

There were fastener locking tabs in the front fender which were a bear to reach and punch away from the hex head bolts. Yeah, I know, this photograph sucks, but we had to use it to show the locks.

We removed the wheel first. Not so fast. I had to unbolt the calipers first and discovered the 12-point metric sockets. Everything on that Showa front end was metric even the Allens on the bottom of the lower legs. One was easy to reach, the other a pain in the ass. I needed a long metric Allen.

Here’s a quirk. The lower legs were drained of 11.1 ounces of front end lube. I thought that the lower legs would just slide off. Not so. You need to remove the seal retaining rings then off come the lower legs popping the seals free. We were forced to replace the seals.

I removed the two screws that hold the taillight lens in place. There’s a junction box behind the taillight held with one large 1/4-20 Phillips screw. The plugs for the turnsignals all snap out of the junction box. The box came loose easily, but the chrome taillight ring was stuck. I thought for sure there were fasteners on the inside of the fender. Not so kimosabe. It was just stuck with an adhesive pad. Once loose we discovered that it was plastic along with the rear fender tip–can’t go to powder coat. We had to sand (wet and dry 600) and paint those elements ourselves.

After all the parts were removed, we laid them out and took a picture of the lot for an inventory. Then each component was carefully wrapped in bubble wrap and boxed. Powder coating would take a couple of weeks. We also wrote up an inventory for Custom Powder Coating and made a copy for ourselves. I looked longingly as the UPS man hauled the heavy carton away with more than 80 parts inside.

We nabbed Custom Powder Coating as a sponsor because several of the staff are large fans of powder coating when building custom bikes. We’ve discovered that if we can build a frame clean enough, we can have it powder coated for a strong, resilient finish at a fraction of the cost of custom painting. There’s other benefits. If you want you’re sheet metal painted by someone in Tim-buck-too, you don’t have to ship the frame, wheel rims and brackets to the high-buck artist. Have them powder coated and send a sample of the finish to your creative-one.

We recently used this formula with a Shovelhead being built at Strokers Custom Bikes, formerly Dallas Easyriders. Rick Fairless who owns Strokers turned us on to Custom Powder Coating. The painter for the project is Harold Pontarelli of H-D Performance out of Vacaville, California. We sent the sheet metal to Harold and the frame and hardware to Steve Marts of Custom Powder coating in Dallas (214) 850-0011.

Amazing shots from Custom Powder Coating in Dallas. Are we good or what?

Steve has been in the custom coating industry for nine years. For 15 years Steve has had the dirty job of coating patio furniture. Steve and his wife Debbie prefer to run a job shop capable of coating hockey goals to bike frames. They can coat dragster bodies up to 20-feet long. Their oven is 6 feet high, 6 wide and 22 feet long. They coat four-wheeler valve covers by the thousands. They coat frames for American Iron Horse and they can virtually match any color using Prismatic Company powders that are dry blended in the Custom Color blending house. Send a swatch to match colors and they can rock.

When I asked about chromed parts Steve said, “If the chrome is fresh and new we brush blast it for proper adhesion and powder coat the part. If the chrome is flaking or old we’ll take it to a chromer to have it stripped.”

Electrically charged parts were sprayed with the powder of our choice–black, before being baked.

As an indication of the toughness of powder coating Steve discussed removing it. “It’s a bitch,” Steve muttered, “It’s so strong you can’t sandblast it off so I heat the parts to 750 degrees and it rolls into balls and runs off. Then I can blast the remaining finish.” Unfortunately, that process won’t work on some aluminum, “It will burn,” Steve added.

Okay, so here’s the basic process. Keep in mind that if you need bondo, you can’t powder coat. Bondo can’t handle the heat. Although, there is a filler now available that will take powder. Make sure all the bearing races are removed. Strip the parts as much as possible and clean them for the best adhesion. Bad welds will be smoother, but they’ll still be bad. We discovered that malady when we built the blue flame. The frame looked terrific powder coated metallic blue, but my welds still sucked. I finally coughed up the cash for a MIG welder. On the other hand we had the frame back in a week and were assembling the bike while Harold poured his magic on the sheet metal. The powder coated frame made all the difference in the timing for the ride to Sturgis. Steve recommends giving him two weeks to run through the process. He runs two shifts a day for four days a week. Only one shift on Saturdays.

Masking is the first process after cleaning, sandblasting or bead blasting. Then the part is prep sanded. Steve has discovered that the powder holds better if the part is warmed prior to the powder painting process. With the pre-heated part the paint immediately begins to melt and doesn’t flock on the component.

Each part is powder coated twice and sometimes three times. There is a base, translucent for metallic, candy’s, and clear for depth and protection.

During the long day, while parts were away, we took turns taking fasteners off the diagram paper, sticking them in a sheet of cardboard and spray painting the heads with a heavy industrial gloss black.

We ordered the new fender mounted license plate bracket, but when it arrived it had a long strip of reflective tape along the bottom. That 1/2-inch of metal had to be removed with a hacksaw, filed flat then wet and dry sanded. Then we sanded the chrome finish with 600 wet and dry and painted it with heavy gloss black.

Drilling holes in the fender for the new license plate bracket.

We needed to reshape the fender bracket. It was designed to be installed against the curve of the fender above the taillight, but we moved it below the taillight.

We used a two-part metal painting process for best adhesion.

Ah, that bastard brake pedal. We finally pried it loose, cleaned it with solvent, sanded it and painted the sucker ourselves.

The mag wheels were mounted with Avon Venom tires with a 150 strapped to the rear rim. The Tires were balanced and we installed the new floating rotors with black centers. My plan was to add a taste of color to the wheels with pinstriping. We discovered that the 150 was a tight fit for the King. It seems that later model Softails and Dynas are set up for 150s with narrower belts, not Touring models. We had to space the pulley away from the wheel .150 inch. Even then is was close. A bikernet reader suggested that we machine the brake caliper bracket .250-inch and add that amount to the left side wheel spacer. Pablo from Charolette H-D said that the rear wheels are slightly off center, but the manual calls for the front and rear wheel to be in line. I’m investigating further. We also discovered a problem with pinstriping the wheels. The new H-D cast mag wheels are aluminum. My striper, George, told us that the striping won’t last. Another source said that if I stripe then clear it will hold. Still investigating.

Here’s one of the spacers we used which is about .050. It wasn’t enough. Not even close.

Here’s a shot of one of the new rear axle adjusters that pull the larger axle back simultaneously. It’s not easy though. I had to set the bike on the ground as I tightened the right side, but I had to hold the left side in place or the belt adjustment changed.

An American Rider deadline was looming ahead when the UPS man knocked on the door and announced the arrival of the massive powder coating box. I was relieved to have all the parts back. I removed the spoked rear wheel by snapping off the axle clip ring with a small flat bladed screwdriver and loosening the axle nut. We spun it to release the pressure on the belt (from the left side). The trick to removing the rear wheel was the brake caliper. It seemed to lodge itself between the rim and the swingarm. It took some fidgeting to free the two elements. The new mag wheel slipped into place easily. We discovered, while returning the axle into position, that we needed to insure the belt adjuster would swing passed the shock mount, or it was stuck.

We went at the installation like two kids assembling a Christmas toy. We assembled the turnsignals with a touch of industrial lube to allow the plastic reflectors to slip back into their rubber housings and into the black shells. We referred to the factory manual for torque specifications. Then I used Frank Kaisler’s wire tool (see tech tips in Wrench’s Garage) to hold the two wires in place so that I could solder the junctions. “Don’t forget to slide on 1-inch of shrink tubing before you solder these puppies,” I told Nuttboy who was fighting the other turnsignal into place with a tiny Allen wrench.

Nuttboy ground and shaped the license plate to fit the new bracket. The rear end was looking trick as we plugged the connections back together and replace the taillight. Then using copious amounts of blue Loctite we started to replace the bag roll bars, but didn’t tighten anything. We used our schematic on the bench to insure we were grabbing the correct fasteners and followed the parts from the roll bars to the fender rails. (Note: that during this process if you feel the need to remove the rear axle in the near future, don’t tighten the lower bag rail. It interferes with the axle.)

Once everything was in place, we tightened the fasteners. About the time we were leaning toward the Torx screws with a ratchet Sin Wu sauntered into the garage and pointed out a long strip of U-shaped rubber. She has a knack for timing that uncanny. The rubber strips back the saddlebag support bracket. I also noted that the long piece goes on the rear edge and the short piece on the front. Once all the elements were in place and aligned we started at the front and tightened toward the back. The saddlebag quick-release mounting brackets were also installed loose. Then we placed the leather covered bags on the bag rail and pushed the studs into place. Only then could we tightened the mounting bracket, 1/4-20, bolts. Watch that they don’t move during the last swing of the wrench. Keep them in line with the bags or installing and removing the bags will be a chore.

Continued On Page 3

Road King 4/18/03 Part III

By Robin Technologies |

Bad shot, but it’s the horn all blacked out and still grimy.

A shot of the spacer made to eliminate the rear shift lever.

We were getting stoked by the changing appearance of the King. The black was giving it unity. I re-greased the shifter shaft and installed the back linkage in a vertical position then tightened it. We eliminated one of the shifter pedals for my big feet and installed the remaining one with Loctite and a 1/4-20 Allen or socket head fastener. We cut a 3/4-inch chunk of 1-inch O.D. mild steel tubing for a spacer to eliminate the other pedal. The main part of the linkage to the transmission we had powdered but sprayed the flexible links and fasteners at each end.

We powder coated the center section of the shift linkage, but had to spray paint the flexible adjusting links and fasteners.

We assembled the kickstand by putting the jiffy stand in place then hooking the spring to the tab, then all four blacked fasteners were unscrambled and slipped in place. The two short 5/16 bolts went toward the front. A long one with a nut fit in the top rear bracket hole and a long one without a nut screwed into the rear footboard bracket. Then the footboard was replaced.

We had one element left to complete. We still needed to put the front end back together. I cleaned the interior of the lower legs with solvent to insure we would have a solid seal at the bottom since there are no gaskets. We had to slip the fork tube out of the trees. We replaced the small aluminum collar and inserted the tube into the lower leg. Then the socket head bolt was replaced and carefully tightened.

I must apologize for not taking shots of the front end assembly. I get caught up with wrenches and forget the camera.

Here’s the black Street Stalker front fender in place using new H-D brackets. The new mag also adds to the black along with the black center floating rotors. Looking Sharp.

We turned the leg over and with a seal tool carefully tapped the new seals in place and added the retaining clip. We removed the seal tool and slid the fork tube up through the bottom tree, passed the pinch bolt, added the fork stop rubber (don’t forget it!) and pressed the tube into place in the top tree. Nuttboy held it firmly while I torqued the pinch bolt. Lastly we added 11.1 ounces of fork tube fluid in each leg and then tightened the fork tube cap with its rubber washer. We torqued the rotor Torx fasteners to 25 foot pounds and broke off our Torx tool. I think I was over doing it. The new fasteners came with locking goo in place, no Loctite necessary.

We noticed that one of the new hydraulic brake lines was rubbing the fender, so we adjusted the position.

We lowered the King until the axle was lined up, then slipped it through with spacers. Had to check the manual and discovered that one of the spacers (on the left) was longer than the right. I instructed Nuttboy to hold the axle in alignment and started to install the collar below it (on the right leg) with the two metric nuts. I torqued the axle to 50-55 foot pounds, then Nuttboy tightened the fork cap fasteners on his side to insure the wheel was square with the forks. Finally we tightened the Allens that held the new jet black Street stalker front fender in place and bolted the calipers in place. I used plenty of Loctite, not those damn stock locking tabs.

I held up my side of the Nacelle and Nuttboy did the same. They didn’t fit. Could the coater have switched components? Could they have been bent in shipping? Didn’t appear so. Perhaps the metal shields flexed in the 425 degrees of heat. We were stuck. I called Steve at Custom Powder Coating. There was no way the nacelle was damaged, but maybe, just maybe the 425 degrees of heat allowed one side of the Nacelle to flex. We may never know.

The next day, in the mail, I discovered the new Harley 2003 Genuine Motor Accessories and Genuine Motor Parts Spring Supplement. On the cover was a fully blacked out King front end. I ordered two new nacelle covers.

A couple weeks later the new nacelle covers arrived. They don’t come with the rubber headlight fasteners. You need eight and I ran to the local H-D dealership. They were an inexpensive 4.97 for all eight. They slip right into place. We replaced the rubber cable guides and the nacelle was ready to be replaced. With it held in place with the side, stainless, dome nuts we slipped the blacked riser cover down over the nacelle lip, which held it in place. Then I replaced the two Phillips screws in the riser cover with blue Loctite, then popped the plastic fork lock guide in place. I was then faced with the most awkward screw on the King. The thin Phillips screw that holds down the front of the riser cover. I had to slip a massive washer in under the top of the nacelle and line it up with the screw. I rocked the bolt to hold the washer while slipping the 5/16 nut in under the nacelle and lined it up. With Loctite on the screw I tightened it down carefully holding the open end wrench with one finger while working a Phillips screwdriver on top while Sin Wu pressed the Nacelle halves together. Quit a trick.

After the bike was assembled I touched up fasteners with good old Rustoleum. I’ve used it all my life and still can’t spell the word.

Last motion was to replace the nacelle trim before the headlight. The still-chrome trim hooks in the riser cover then one stud slips between the nacelle halves. Another Loctited 5/16th nut spun into place.

Then I started the headlight ring. I almost forgot to plug the headlight in, but caught myself. All eight black Phillips screws rolled into place carefully. They’re a unique fastener. A brass nut is buried in rubber which slips through a 1/4 inch hole in the nacelle with a lip toward the outside. The screw slips into the rubber grommet until it reaches the buried brass fitting. As it pulls the fitting forward toward the back of the nacelle, the rubber expands creating a bond. Sort of a rubbermounting process for the headlight. Finally we replaced the spring in the blacked out headlight ring and snapped it in place on the top of the headlight assembly, then locked it down with a short Phillips sheet metal screw on the bottom. Done deal.

Not a great shot. The bike was still dirty, but you get the notion. Wait until you see the next segment. A few final touches and this puppy will sing.

–Bandit

Mudflap Girl FXRs, Part 7 My Son’s almost Grip Ace Wired

By Robin Technologies |

Click here to read the chapter 6: http://www.bikernet.com/pages/story_detail.aspx?id=10268

This is a blast. The year is just starting and shit is flying at us everyday. Gary and the gang from next door delivered enough steel I-beams and C-beams to build a deck, and in two days a gang from Long Beach will deliver a pool table into the Bikernet barracks and gym. And if we are lucky, (today is Wednesday the 3rd of January 2012) we will have all the elements in place to fire my son’s Mudflap girl bike on Tuesday, while IKustom films the event for his TV series. We may even have a live Mudflap Girl in the shop.

While my Mudflap baby is waiting on a custom Saddlemen seat, I hurriedly shifted back to my son’s version of the FXR. We needed to wrap up some minor elements, and hit the Ace Grip/Wire Plus wiring. Then we would be ready for another Saddlemen seat.

Before I could finalize the primary system, we needed to order a rear belt from Biker’s Choice. One of the major benefits of chains over belts is the mechanics. We had to pull the whole motorcycle apart to install the belt. It had better be the proper length–it was.

It took a while to clearance the outer primary around the Rivera Primo Inc. inner belt drive system. I needed to have the mid controls in place before I could install the weld-on Mr. Lucky kickstand that contoured the frame. All the appropriate elements needed to be in place. With the final linkage in position through a plastic tube that acts as a bushing, we moved forward, we installed the Primo Rivera belt and clutch system, but I still had to make a clutch pushrod. I removed the tranny pipe-side cover and checked the throw-out bearing type.

We finally made it, although my hard-working son was absent. At first, I grappled with the mentoring scenario. I shouldn’t lift a wrench without him on hand. Two elements pulled me from the tough-love fatherly position. Frank is struggling to support two ex-old ladies and three kids. This is a lesson to every young man. Beware.

You can imagine the tug-o’-war that goes on constantly. I’m not completely innocent. I was predominately an absentee father. A decade ago, I spent some time on the board of three group homes for abandoned kids. These kids had no folks and the effects were manifested in their lives like that tsunami in Japan. Kids need parents. Our society is all jacked up when it comes to sex and kids. I won’t go there, but the bottom line is simple: Kids need to be carefully planned and looked after. They need both folks and a stable family. So, I said, “Fuck it!” I’m moving forward to finish Frank’s bike, whether he’s on site or not.

Besides, we are rolling into 2012 and need to wrap up these bikes, road test them, break them in and prepare for the ride to Sturgis. Actually, I started to bug two of my grand kids who are 16 and 18, and very sharp, but ditched high school. Frankie or Frank Jr. is working as a tattoo artist, and I encouraged him to set some goals for 2012. He stepped up to take over the XS project, and came over to help with his dad’s bike. It was good to see him involved.

With the mid-controls in place, I could breakout Mr. Lucky’s weld on kickstand and begin the installation. I needed to make sure to assemble it is a safe location. Any time you have springs, ball bearings, and tiny setscrews, you need to be careful. It’s not a bad notion to perform assembly over a soft rag, so parts can’t vanish into a black hole.

This is actually a simple operation, but it takes 220 volts and a welder, either TIG or MIG. I slipped the supplied spring in the body of the kicker arm, then the ball bearing on top of the spring. Then the bare metal piece is carefully slipped into place. It’s easy to tell how to position the arm and the ball, since there are just two ball indents. So, the flat side of the bare chunk faces forward. Before final assembly, I will completely grease the ball, the spring, the mating surfaces of the weld-on portion, and the axle pin.

With the kickstand arm pushed and held against the spring and the ball, a second set of hands slipped the axle pin into place and started the fine threads. Again, upon final assembly I will blue Loctite the pin threads.

Then I faced the delicate, do, or die job: positioning the weld-on portion. We fitted it several times, then marked the position with a felt pen on the bottom frame rail. Then I loosened the lift clamp, strapped, and rolled the bike over toward the primary side with a strap, until I had it positioned at just the correct angle. This is always a trick. Too far adds dangerous weight to the kickstand and makes the bike awkward to maneuver. If the bike sets too upright, it’s iffy to park, and as with my Shovelhead, I can’t park it in many positions. It wants to pop over. Even the wind can push it over.

With all the touchy elements considered I positioned the Mr. Lucky kickstand against the frame, and folded it up to see how it fit in the running position. It ran smack into the mid controls system, so I adjusted, and we are thinking about running a piece of hose, or even shrink wrap up the kickstand arm to prevent vibration.

With the bike leaned and the arm in the extended position I made two guide marks on the weld-on portion and on the frame rail. Then I could straighten the bike for tacking. I tacked the weld-on bung on both ends, and then tested the position against the straps. Then I ran a bead along both sides with my MIG welder. I plan to double up on the welds with the TIG, once we pull the bike apart.

We were cranking along, but had to step back to my Mudflap girl bike, since the shocks faded and we needed 1-inch longer shocks. We had to pull them apart and add to the bumpers so that the fender would not hit the tire. Progressive has various bumper lengths. The key here is to dismantle the shock, install them, lower the bike until it hits the fender, and make a bumper measurement. Progressive makes hard plastic bumpers in various thicknesses. We made a special tool, used a drill press, and took the shocks apart several times, until we had them dialed in. The key when measuring for shock length is to consider about 1-inch of fade once the shock is installed. We shifted back from a 12-inch shock to 13-inch Progressives.

So, my Mudflap baby was hauled to Saddlemen for the gurus of seats to evaluate. I’ve toured many companies over the years, and the Saddlemen operation is impressive. I met guys who have been making seats for 25 years, and their sons are now working with them. It’s truly a family of operators. They’re very involved in an ongoing hunt for the perfect seat technology. First, they studied foams, and then gels, and now this new design that affords a buffer area to relieve pressure on the spine. We discussed styling and design. Then we peeled out to let the masters consider the options.

We faced an open warm, clear, SoCal day and jammed back into the shop. I started by installing the Biker’s Choice regulator bracket and the Spyke regulator into position. Ray turned to install the S&S carb, since we were faced with the opportunity to install and complete the Crane cam and lifter system. Most Crane products are manufactured by S&S, including their roller rockers for twin cams.

We discovered a crazy tough oil cooler system from Baker Precision, on Signal Hill, and I tacked studs into place on the front frame rails. It’s made in Canada for automotive power steering oil cooling applications. After we installed the belt, we discovered a problem with the rear fender and the belt slot. The fender needed to be removed and reshaped. I also needed to develop a rear brake anchor.

That was the day Buster came by and we decided to go for a ride. I crashed, returned to the shop bruised, but the Shovel kept running. I thought about kicking back and watching Sunday night football, but I needed to pause it, and jammed back to the shop to keep the program rolling on Frank’s bike. While Ray installed the S&S Super E carburetor, I removed the rear wheel, the rear fender, cut a new slot in it, and drilled a hole where the Choppers Inc. Mudflap Girl taillight stem hit the fender.

So here’s the snafu. It surfaced the last time Frank came over. “I didn’t want mid controls,” Frank said. “I wanted forward controls. It’s all your fault.”

In the next segment, we will deal with his changing desires–kids. Then we’ll fire his bike, with the ACE grip wiring system to lead the way.

Sources:

Spitfire

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Bub

S&S

Mr. Lucky

Bikernet/Cycle Source 15th Anniversary Subscription Sweeps Bike Build, Sponsored by XPress Lids