Mudflap Girl FXRs, Part 8 Wiring World

By Robin Technologies |

Since last time, my Mudflap Girl is still over at Saddlemens waiting on a custom seat, but good news filtered into the shop this week. Next week, we should move forward.

Then my son made his dire announcement: “I wanted forward controls,” he said. “It’s all your fault. I agree with Jesse James, you’re nothing but trouble.”

I struggled with the assembly of his mid controls for months. I kicked the Handy steel lift and stubbed my big toe, knowing full well I stood on the right side of the law, and my son was out to lunch on this issue. But as the dad in this scenario, I should be the bigger man. Besides, mid controls can be a puzzling pain in the ass. I dug through my lockers of old parts and found enough components to make up the shift side of forward controls, but I didn’t have the rear brake master cylinder, or the lever and plate. I kept digging.

I reached out to Paul Cavallo, the boss of Spitfire Components, and our Mud Flap Girl frame builders. I thought if I could order a set of the weld-on ½-inch forward frame mounts, I would find the remaining billet aluminum controls parts at the Long Beach swap meet.

Here are some thoughts when it comes to mid controls versus forward controls: Mid controls tighten the looks of the drive train, but make it harder to work on your primary, clutch, oil pump, engine and pipes. They can be a tight, cumbersome addition. On the other side of the coin, they enhance the appearance of any bike by allowing the frame to slither unencumbered until it fades under the engine. And from a handling perspective, mid controls can actually lesson the weight on the lower back.

Okay, so forward controls are sort of out of the way of the engine, the pipes, and the primary. They are easier to install and adjust for long-legged bastards. So what the hell; we started to shift gears. Paul Cavallo assured us of a new shipment of their super-simple to install and bleed forward controls, so we stepped up.

Oh, regarding Jesse James. He complained to the publisher of Heavy Duty Magazine, in Australia, when I didn’t vote for him during the big American Chopper Build-off, in Vegas a couple of months ago. A year ago Heavy Duty asked me to fill in for Jesse, since he was acting up, so I started writing a column for the largest Harley mag in Australia. But now I’ve been fired, because Jesse threatened the publisher, “It’s either him or me.”

In the meantime back at the Mudflap girl, I grappled with the electrics. I had a few issues to mess with. I planned to install a Wire Plus speedo-dash to Frank’s Spitfire T-bars. Grip Ace would handle switches with their electronic module, and the ignition was a Crane Hi-4, a versatile unit. The Hi-4 can be set up to fire a single-fire system, dual-fire, dual plugs, tach, VOES, you name it. I also had a Wire Plus wiring system as backup. It contained the starter relay, blinker relay, and wiring schematic.

A quick sidebar: We built this belt guard out of solid steel rod and strap. I’m a stickler for strength. I like looks, but strength is everything. I would rather the rear strap was 1/16-inch thicker. I will keep an eye on this puppy during the break-in period. Swingarms are bastards for abuse; that’s why mounting fenders to swingarms is particularly tough. Every bump, vibration, or shock a tire endures is transferred to the swingarm, and anything attached to it. Unlike a rigid frame, a swingarm is designed to move rapidly to cushion the ride.

I dug around and found an old ignition switch with an old worn brass key. I looked for a thick washer with the same I.D. as the switch’s O.D. and welded it to the top motor mount. Seems a very accessible position for a switch, and close to the coil and ignition system wires.

At first, I thought about running a circuit breaker on the other side of the motormount, and installed one. As it turned out, I never ran a wire to it, so I removed it.

Since S&S took over the classic Crane Performance products line, we had access to Crane products. My son’s performance aspects will all be Crane and S&S, including the E-carb, a Crane cam, adjustable pushrods, etc. First, I installed the Crane sparkplug wires. This is one damn thing I take my time with. It’s too easy to cut a wire short. I find the kits often lacking the proper pieces, or pieces too tough or tight to install without going nuts. It’s good to collect spare parts. Don’t throw anything away, goddamnit.

For instance, this kit comes with the sparkplug end of the wire already fastened to the cup and lead. I couldn’t find a brass fitting for the straight-in coil sleeve end, but I had some in another kit. I followed the directions and greased the inside of the rubber boot before I started. With the wire and the boot greased, I slid the boot past its position, carefully cut the insulation back about ¾ of an inch, and then folded the carbon lead over the insulation. I carefully crimped the brass fitting into place using several different configurations of pliers, since I don’t have any special tool for this operation. Notice how the brass must bite into the plug wire insulation.

It’s a delicate, tough operation, but once the boot is pulled into place, the tight rubber will hold the fastener and the wire firmly. My son, Frank, the tattoo artist, stopped over and we handled mounting the controls on the bars. These controls were designed for stock application, and we would not use the stock switch housings, because we were dedicated to using the new Grip Ace system due to its simplicity, but we’ll get into that later in this chapter.

We installed the modified handlebar controls with some 1-inch Dewey wheel spacers to make up for the missing bulky switch housings. We were installing the Biker’s Choice Motion Pro clutch cable when Erik Lundmark, from Lundmark Studios, popped in and started filming us for his new TV series, Kustomz. It’s so long between shoots, I forget about the creative effort, but it may pop onto a cable channel near you someday soon.

This build is interesting, because it forced me to go in different directions and away from another rigid frame. In fact, some readers applauded the variation from rigids to something more long-road worthy, and the FXR platform was perfect. I’m beginning to understand why some builders always use the same tried and true components over and over. I can use the same parts, and they fit the same way as the last build, with no surprises. Since Ben Kudon at Rivera asked me to try their new belt system designed for use in a stock primary, I agreed to try it. No big deal, right? The bike was built in 1996, and we stumbled across a set of 1989 primaries.

As it turned out, the starter jackshaft in the early primary was much larger in diameter than late model units, with less pinion gear teeth, but much larger. Consequently, the Spyke starter wouldn’t work and I had to return it. Then the jackshaft was all wrong, and finally, the ring gear on the Rivera Primo Inc. clutch was wrong. Ben sent me another ring gear and it wouldn’t fit on the Rivera clutch shell. He thought I had a stock clutch. What a minute; I was building this with a primary, primarily to use their new system. Switching ring gears was not fun, due to their red Loctite-coated fasteners, and we had to drill out several locked-down Allens. Fortunately, Rivera-Primo makes ring gears for almost any application, so I was covered.

Ray C. Wheeler and I tried everything, including WD-40 and stronger penetrating lubricants. Ultimately, we rounded Allen wrenches, drilled out a few, and used easy-outs. Then the clutch rolled back into shape with the new Spyke starter and jackshaft assembly, but we were missing one dinky element. That surprise came later.

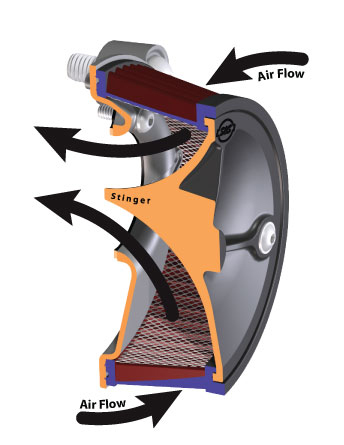

Next, we started to wrap up the carburetor install with the new S&S Stealth Air Cleaner design. Here’s what the gang at S&S said about this system: Everybody likes to go fast, but not everybody likes to advertise. The S&S Stealth air cleaner kits are for the rider who likes to go fast, but wants to be just a little bit sneaky. Get all the performance of the S&S design, including the air directional “stinger” cone in the filter, and hide it under your stock Harley-Davidson air cleaner cover.

Owners of 1999–2012 Harley-Davidson big twins can install the new S&S Stealth air cleaner kit and pick up more power, using their stock air cleaner cover. Nobody will know because it looks entirely stock. We’re talking sleeper hog!

Owners of 1993–1999 big twins with Evolution engines and owners of Sportster models can get the same performance kick, but won’t be able to use their stock covers.

We didn’t want to use a stock cover or be stealthy about it. S&S makes a series of their own aluminum cover designs, but we gave it the Mudflap Girl touch from 2Wheelers just before they packed up and rolled out from Denver, heading east for Daytona Bike Week. I liked this new system a lot, from the lightness of the components to the auto-venting system built into the bracket. No tubes or hoses needed. This installation was a breeze.

Something sneaky slithered around the shop about the time a cold chill slipped over the LA basin. I discovered how aerodynamic Frank’s Spitfire tank was and how well it fit on our Bonne Belle 45 being built for Bonneville this year. I stole the sleek tank off Frank’s bike and mounted it to the 45 Paughco frame. It fit like a glove. I ordered a 3.8-gallon tank from Paughco, and it arrived just after the winter show series. Ray helped me grind off the rubber-mounting tabs.

I started the wiring process, knowing full well the tank would arrive any day, and I would need to reroute some of the wires. I stuck the Grip Ace wiring module in the backbone of the frame, installed the Grip Ace grip, and tried like hell to find quiet, unencumbered time in the shop alone to perform wiring magic. It’s not difficult, but it takes quiet thought, testing, wire running, wire accounting, and figuring.

It’s too easy to run a wire, and then discover another wire needs to follow the same path, such as the neutral switch wires running off the transmission. That wire (one is a ground wire) can run up to the Wire Plus speedo, but the oil pressure switch will follow the same route, as will the speedo pick-up, the wire to the starter solenoid, and maybe the wire to the brake light switch.

I’m using the longer spin-on oil filter to hold the alternator/Spyke regulator plug in place and give the bike more oil capacity. We used the new JIMS tool to pull the filter, and we replaced it by hand. I mistakenly thought I could wire this bike without a circuit board, but quickly shifted gears after I made a small bracket to hold the 30-amp circuit breaker under the seat. Then I welded a small mounting plate to the bracket for the board, and everything started to fall into place. I found some quiet time and started running wires. When I first wire any bike, I draw a schematic with the basic components and start an initial map. It’s a damn good idea, because it’s super easy to forget one item, like the flasher unit for the turn signals.

I also grappled with the VOES switch. I reached out to Bruce Tessmer from S&S for input. I’ve run maybe one VOES switch in my building career, so I didn’t see any reason to go there. Bruce explained the reason behind the switch running off a vacuum tube from the carb. It is designed to help prevent pinging in high performance engines when they don’t have access to high-octane fuels, or run in high altitudes. Since we don’t generally encounter those problems, and we are running near-stock compression engines, I ducked that aspect, and wired the Hi-4 system into place.

My grandson, Frank Jr., recently took over the XS build, and he rolls over to the headquarters on a weekly basis. He’s a worker, willing to sweep the floors, turn wrenches, anything to assist in the process. He’s turned into a major asset around the shop, and has recently become the designated rider for 45 Bonne Belle, since our Australian female tattoo artist had to bow out for this year. Frankie, 18, is also a tattoo artist in the making. We dove into re-installing his XS engine into the Mr. Lucky, Paughco-built frame, and Frankie is now helping with the Bonne Bell build.

Next, we will fire Frank’s FXR, check the wiring, adjust the carb, and we will both be in the market for seats. Mine is scheduled to come from Saddlemen and Frank’s from Le Pera. Hang on. Oh, and we’ll come face-to-face with our jackshaft learning curve. I’m getting anxious to ride. I’m scheduled to meet the Saddlemen crew in two days.

Spitfire

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Road King 4/18/03 Part III

By Robin Technologies |

Bad shot, but it’s the horn all blacked out and still grimy.

A shot of the spacer made to eliminate the rear shift lever.

We were getting stoked by the changing appearance of the King. The black was giving it unity. I re-greased the shifter shaft and installed the back linkage in a vertical position then tightened it. We eliminated one of the shifter pedals for my big feet and installed the remaining one with Loctite and a 1/4-20 Allen or socket head fastener. We cut a 3/4-inch chunk of 1-inch O.D. mild steel tubing for a spacer to eliminate the other pedal. The main part of the linkage to the transmission we had powdered but sprayed the flexible links and fasteners at each end.

We powder coated the center section of the shift linkage, but had to spray paint the flexible adjusting links and fasteners.

We assembled the kickstand by putting the jiffy stand in place then hooking the spring to the tab, then all four blacked fasteners were unscrambled and slipped in place. The two short 5/16 bolts went toward the front. A long one with a nut fit in the top rear bracket hole and a long one without a nut screwed into the rear footboard bracket. Then the footboard was replaced.

We had one element left to complete. We still needed to put the front end back together. I cleaned the interior of the lower legs with solvent to insure we would have a solid seal at the bottom since there are no gaskets. We had to slip the fork tube out of the trees. We replaced the small aluminum collar and inserted the tube into the lower leg. Then the socket head bolt was replaced and carefully tightened.

I must apologize for not taking shots of the front end assembly. I get caught up with wrenches and forget the camera.

Here’s the black Street Stalker front fender in place using new H-D brackets. The new mag also adds to the black along with the black center floating rotors. Looking Sharp.

We turned the leg over and with a seal tool carefully tapped the new seals in place and added the retaining clip. We removed the seal tool and slid the fork tube up through the bottom tree, passed the pinch bolt, added the fork stop rubber (don’t forget it!) and pressed the tube into place in the top tree. Nuttboy held it firmly while I torqued the pinch bolt. Lastly we added 11.1 ounces of fork tube fluid in each leg and then tightened the fork tube cap with its rubber washer. We torqued the rotor Torx fasteners to 25 foot pounds and broke off our Torx tool. I think I was over doing it. The new fasteners came with locking goo in place, no Loctite necessary.

We noticed that one of the new hydraulic brake lines was rubbing the fender, so we adjusted the position.

We lowered the King until the axle was lined up, then slipped it through with spacers. Had to check the manual and discovered that one of the spacers (on the left) was longer than the right. I instructed Nuttboy to hold the axle in alignment and started to install the collar below it (on the right leg) with the two metric nuts. I torqued the axle to 50-55 foot pounds, then Nuttboy tightened the fork cap fasteners on his side to insure the wheel was square with the forks. Finally we tightened the Allens that held the new jet black Street stalker front fender in place and bolted the calipers in place. I used plenty of Loctite, not those damn stock locking tabs.

I held up my side of the Nacelle and Nuttboy did the same. They didn’t fit. Could the coater have switched components? Could they have been bent in shipping? Didn’t appear so. Perhaps the metal shields flexed in the 425 degrees of heat. We were stuck. I called Steve at Custom Powder Coating. There was no way the nacelle was damaged, but maybe, just maybe the 425 degrees of heat allowed one side of the Nacelle to flex. We may never know.

The next day, in the mail, I discovered the new Harley 2003 Genuine Motor Accessories and Genuine Motor Parts Spring Supplement. On the cover was a fully blacked out King front end. I ordered two new nacelle covers.

A couple weeks later the new nacelle covers arrived. They don’t come with the rubber headlight fasteners. You need eight and I ran to the local H-D dealership. They were an inexpensive 4.97 for all eight. They slip right into place. We replaced the rubber cable guides and the nacelle was ready to be replaced. With it held in place with the side, stainless, dome nuts we slipped the blacked riser cover down over the nacelle lip, which held it in place. Then I replaced the two Phillips screws in the riser cover with blue Loctite, then popped the plastic fork lock guide in place. I was then faced with the most awkward screw on the King. The thin Phillips screw that holds down the front of the riser cover. I had to slip a massive washer in under the top of the nacelle and line it up with the screw. I rocked the bolt to hold the washer while slipping the 5/16 nut in under the nacelle and lined it up. With Loctite on the screw I tightened it down carefully holding the open end wrench with one finger while working a Phillips screwdriver on top while Sin Wu pressed the Nacelle halves together. Quit a trick.

After the bike was assembled I touched up fasteners with good old Rustoleum. I’ve used it all my life and still can’t spell the word.

Last motion was to replace the nacelle trim before the headlight. The still-chrome trim hooks in the riser cover then one stud slips between the nacelle halves. Another Loctited 5/16th nut spun into place.

Then I started the headlight ring. I almost forgot to plug the headlight in, but caught myself. All eight black Phillips screws rolled into place carefully. They’re a unique fastener. A brass nut is buried in rubber which slips through a 1/4 inch hole in the nacelle with a lip toward the outside. The screw slips into the rubber grommet until it reaches the buried brass fitting. As it pulls the fitting forward toward the back of the nacelle, the rubber expands creating a bond. Sort of a rubbermounting process for the headlight. Finally we replaced the spring in the blacked out headlight ring and snapped it in place on the top of the headlight assembly, then locked it down with a short Phillips sheet metal screw on the bottom. Done deal.

Not a great shot. The bike was still dirty, but you get the notion. Wait until you see the next segment. A few final touches and this puppy will sing.

–Bandit

Bikernet/Cycle Source 15th Anniversary Subscription Sweeps Bike Build, Sponsored by XPress Lids

By Robin Technologies |

That’s right. You can enter by filling out the coupon, subscribing to Bandit’s Cantina on Bikernet, or to the Cycle Source Magazine. With a Crazy Horse 100-inch engine, and a frame from Texas Bike Works this build is already flying together.

From issue to issue you’ll see your motorcycle being built on the pages of Bikernet and Cycle Source. You’ll witness Gary Maurer from Kustoms Inc. and Ron Harris from Chop Docs bend sheet metal, create one-off components, and shoot one of the sickest old-school paint schemes that you have ever seen…

The team will carefully select components from the best in the industry, including wheels from Ride Wright, electronics from Accel, leatherwork by the master, Howard H. Knight, and controls from Tim at Grip Ace.

“Also, please look at Barnett clutches and let me know what you need,” Prince Najar said. He’s the manager of this process and partner at Biker Pros, who is working closely with our builders, editors, and suppliers.

“Also, Blacksmith Baggerville is interested in creating one-off pegs, brake pedal, grip, internal throttle and air cleaner,” the Prince said.

The parts list for XPress lid chopper build, including a Fab Kevin seat pan and hinge, expands daily.

Gary Maurer plans to split a set of stock fat bobs, modify them and mount them to the Texas Bike Works frame. He will take possession of the frame and Crazy Horse engine this week while the Prince searches high and low for forks cups, a springer front end, tires, rear fender, rear axle, final chain drive components, forward controls, a battery, a Mikuni carb from Rivera Primo, a primary drive system, an air cleaner, front and rear brakes, and the list goes on. Of course the Prince plans on using the D&D performance exhaust system.

“Let your wings fly for now,” Gary said to the Prince in his best motivational sounding voice, modulated by Jack Daniels and soaked in wisdom by some of the best Georgia moonshine.

“Wait,” Ron Harris said, “I have a special request. I need a Goldwing Windjammer fairing.”

“Thanks for reminding me,” Prince Najar said. “I found one, if Maurer will let go of his, then we’re all set.”

Gary Maurer with Jason Ferguson of Texas Bike Works initially designed the hand-built custom frame. Gary sent to Jason a custom bent backbone down to Texas. It features a 1 ¾-inch formed DOM steel tubing arched backbone to be integrated the frame. Jason is an MMI graduate who cut his teeth in Southern California with Johnny Pag and the Biker’s Dream folks in 1993. After the Dream fell apart, but with a great deal of hard knocks experience, Jason peeled out to the Lone Star state, and drove in his stakes in 2006, on the outskirts of Dallas/Fort Worth, in Granbury, Texas.

He spent five years perfecting his first frame jig and has been hand fabricating specialty frames for two years. The fabrication bug inspiration came from the first Motorcycle Mania Discovery show by Hugh King. He watched fabricators work shrinkers/stretchers, English wheels, shapers, and benders, and was suddenly intrigued to try his hand with steel manipulation.

Gary bent the curvy rigid backbone and shipped it to Jason. Jason added 2 inches of stretch up and out, plus an additional 2 inches in the rear. He included 34 degrees of rake in the neck. The rest of the 1 ¼-inch tubing design was up to Jason to enhance lines of the frame and make her flow.

“I don’t have a roller to fabricate those soft bends,” Jason said. But I’m sure that tool rests heavily in the back of his mind. As a kid, his dad was a biker, and Jason was inspired by Arlen Ness digger styles. He hopes to build frames, rollers, and complete bikes around Panheads, Shovels, and Sportsters. His next bike project involves a generator 1966 Shovelhead and a bone stock, never touched Arlen Ness original chassis.

So there’s talented crew for the XPress lid Bikernet/Cycle Source Sweeps biker project, and I would be proud to own any bike built with a Jason Ferguson, Texas Bike Works frame, Fab Kevin components, Crazy Horse engine, and by the crazy team of Gary and Ron. But wait, who the hell is that title sponsor? We are very fortunate to have this coffee company sponsor our build. XPress is a custom French Press coffee cup lid technology, by Smart Cup. Have you heard of French pressed coffee? Well, Smart Cup designed a portable cup that makes a French pressed cup of strong Joe whenever you want it. Over the months ahead, we’ll show you how it works and delivers a superior cup of crushed beans on the go.

Hang on for the next report, and don’t forget to enter, goddammit.

–Bandit

Sources:

Xpress

http://mysmartcup.com/

Crazy Horse

http://www.crazyhorsemotorcycles.com/

Texas Frame Works

www.TexasBikeWorks.com

Kustoms Inc.

KustomsInc@hotmail.com

Chop Docs

www.Chopdocschoppers.com

Fab Kevin

http://www.fabkevin.com/home.htm

D&D Exhaust

http://www.danddexhaust.com/

Wire Plus

http://www.wire-plus.com/

Barnett

Barnettclutches.com

Rocking K Custom Leathers

howard.knight@montana.com

Mudflap Girl FXRs, Part 6 Wiring with Wire Plus

By Robin Technologies |

Wiring is always a treat, unless you use one of those systems in a box like Phil’s speed shop systems. I ran one on my factory racer, and it was a breeze. I’ll try to find a photo. It was designed to mount to the frame seat post. Inside it contained the circuit breaker, the starter relay, the ignition switch, the starter button, high low beam, and horn button. Then a ream of wire rumbled out of a hole. I guided them to the appropriate spots and hook them up. Nothing to it.

In this case, we worked with Wire Plus since they are the masters of wiring kits, Speedos and assorted equipment. They sent me a complete wiring harness with a starter relay, flasher system for turn signals, a 30-amp circuit breaker with mounting strap and rivets. They also included an installation and operator manual for model Wp192, Mid Frame Mount System, with Chopper style harness, with or without turns.

Their manual affords the reader a lighting circuit flow chart, an ignition flow chart, and an accessory flow chart. It demonstrates several ignition switch wiring circuits and handlebar circuits. It even comes with a Wp143 lighting control system for auto-canceling style harness. Actually, I checked the Wire Plus web site and they do make a seat post ignition switch wiring system unit, in a coffin shape, classic, and old school. They also make a cylindrical shaped engine mounted ignition switch housing, and ignition and toggle switches. They have systems that include compression releases–Amazing.

Wire Plus also makes individual wiring products, like their lighting control modules, power modules, plus custom power ports, for plugging in accessories. There’s a reason for going on and on about Wire Plus. Wiring can be a nightmare, and I’m a lazy. I want to be as minimal as possible, for ease and reliability, but I’m fulla shit. Just about the time I think I need to cut turn signals out of my system, someone is wiring in heated grips, or a heated seat, a some sound system, or neon lights under the engine. I avoid anything extra, like the plague. Hell, wire plus make engine mounted electrical port systems, so you can plug in your heated vest, helmet sound system, or whatever.

This is going to be a terrific test. My son’s bike will contain more bells and whistles, and Grip Ace controls in the bars. Tim from Grip Ace from Rivera is coming over to show us how easy it is. On Frank’s bike, we will install turn signals, so anything is possible. We will also wire a metric bike, the XS Yamaha bobber. So, over the next couple of months you will witness three variations, with Wire Plus products.

I start wiring by finding all the components and placing them somewhat in position. Then I search for a place to hide the circuit breaker and a circuit board, or bank of connections. First, we made a trip to the local Marine store and ordered an ignition switch. This included a starter switch, but we were using the Spyke push-button starter mounted to the solenoid. It eliminated the starter relay and any starter switches.

Once I determined a handy location behind one of the Mudfap Girl FXR panels, I drew up a wiring schematic, while referring to the Wire Plus handy manual for guidance. I came up with this nuts notion of hiding the ignition switch under the seat nose, which would position it perfectly for some of the wiring, and run some of it through the backbone of the frame. I grappled with a mounting notion, but Danny came up with the final notion, which took a lot of work, but was highly secure.

Wire plus makes several digital speedos, and several mounting systems for different applications. It was a breeze to mount and wire once I found the mysterious neutral switch connectors, which I ordered from the factory. The WP speedo mounted like a dream on the bars, once I plugged the wiring harness into the rear of the unit, ran the wires under the tank, back to the nerve center for power, then to the speedo sensor, and the neutral switch. Nothing to that one, although I wouldn’t mind running the wire loom through the frame in the future.

Since I was thinking about the rear brake pressure switch, I started to work out my GMA brake systems, and we made some measurements. I ran over to Baker Performance products and in five minutes we had new brake lines cut to size. This was probably the easiest bleeding process I have ever encountered. They were bled and working in no-time. Unfortunately, GMA doesn’t make a clutch lever to match.

On rubber-mounted bikes, I run two grounds. I welded one to the frame and I use one of the Spyke starter mounting bolts as an auxiliary ground. I don’t want to take any chances with the charging system, or the ignition system missing a grounding connection.

I needed to mount an On-On switch in the headlight bucket. It took some hunting for the correct sized switch, then a headlight seal beam from Biker’s Choice, and a lot of digging for a three blade connector. My headlight came from a spot on a police car in the ’30s.

Almost all of my electrical components came from Spyke or Compu-Fire. The Compu-fire ignition system is a breeze. This time I’m running a Compu-Fire single fire ignition system, with their single, dual wound coil, which mounts between the heads, in the standard stock position. It’s all too tight and convenient. Two wires to the coil and one to power and the system is good to go. It’s about that easy to time.

My son showed up with the missing parts for his Bub Bare exhaust system, and we started mounting it. I wish the exhaust guys would make kits with the flanges and retainer spring rings. Some systems come complete, but it’s a drag to run to the dealership, when you’re ready to rock. I understand why they don’t supply them with many system. If the system is replacing a stock system, we just switch out the parts. And these four pieces would jack up the price, but give the customer the option, and the manufacturer could make an extra buck and save the builder time and hassle.

This system slices damn close to $350 and you paint it with whatever heat paint, or heat wrap you like. It’s very similar to my D&D system.

Sources:

Spitfire

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Bub

Mudflap Girl FXRs, Part 7 My Son’s almost Grip Ace Wired

By Robin Technologies |

Click here to read the chapter 6: http://www.bikernet.com/pages/story_detail.aspx?id=10268

This is a blast. The year is just starting and shit is flying at us everyday. Gary and the gang from next door delivered enough steel I-beams and C-beams to build a deck, and in two days a gang from Long Beach will deliver a pool table into the Bikernet barracks and gym. And if we are lucky, (today is Wednesday the 3rd of January 2012) we will have all the elements in place to fire my son’s Mudflap girl bike on Tuesday, while IKustom films the event for his TV series. We may even have a live Mudflap Girl in the shop.

While my Mudflap baby is waiting on a custom Saddlemen seat, I hurriedly shifted back to my son’s version of the FXR. We needed to wrap up some minor elements, and hit the Ace Grip/Wire Plus wiring. Then we would be ready for another Saddlemen seat.

Before I could finalize the primary system, we needed to order a rear belt from Biker’s Choice. One of the major benefits of chains over belts is the mechanics. We had to pull the whole motorcycle apart to install the belt. It had better be the proper length–it was.

It took a while to clearance the outer primary around the Rivera Primo Inc. inner belt drive system. I needed to have the mid controls in place before I could install the weld-on Mr. Lucky kickstand that contoured the frame. All the appropriate elements needed to be in place. With the final linkage in position through a plastic tube that acts as a bushing, we moved forward, we installed the Primo Rivera belt and clutch system, but I still had to make a clutch pushrod. I removed the tranny pipe-side cover and checked the throw-out bearing type.

We finally made it, although my hard-working son was absent. At first, I grappled with the mentoring scenario. I shouldn’t lift a wrench without him on hand. Two elements pulled me from the tough-love fatherly position. Frank is struggling to support two ex-old ladies and three kids. This is a lesson to every young man. Beware.

You can imagine the tug-o’-war that goes on constantly. I’m not completely innocent. I was predominately an absentee father. A decade ago, I spent some time on the board of three group homes for abandoned kids. These kids had no folks and the effects were manifested in their lives like that tsunami in Japan. Kids need parents. Our society is all jacked up when it comes to sex and kids. I won’t go there, but the bottom line is simple: Kids need to be carefully planned and looked after. They need both folks and a stable family. So, I said, “Fuck it!” I’m moving forward to finish Frank’s bike, whether he’s on site or not.

Besides, we are rolling into 2012 and need to wrap up these bikes, road test them, break them in and prepare for the ride to Sturgis. Actually, I started to bug two of my grand kids who are 16 and 18, and very sharp, but ditched high school. Frankie or Frank Jr. is working as a tattoo artist, and I encouraged him to set some goals for 2012. He stepped up to take over the XS project, and came over to help with his dad’s bike. It was good to see him involved.

With the mid-controls in place, I could breakout Mr. Lucky’s weld on kickstand and begin the installation. I needed to make sure to assemble it is a safe location. Any time you have springs, ball bearings, and tiny setscrews, you need to be careful. It’s not a bad notion to perform assembly over a soft rag, so parts can’t vanish into a black hole.

This is actually a simple operation, but it takes 220 volts and a welder, either TIG or MIG. I slipped the supplied spring in the body of the kicker arm, then the ball bearing on top of the spring. Then the bare metal piece is carefully slipped into place. It’s easy to tell how to position the arm and the ball, since there are just two ball indents. So, the flat side of the bare chunk faces forward. Before final assembly, I will completely grease the ball, the spring, the mating surfaces of the weld-on portion, and the axle pin.

With the kickstand arm pushed and held against the spring and the ball, a second set of hands slipped the axle pin into place and started the fine threads. Again, upon final assembly I will blue Loctite the pin threads.

Then I faced the delicate, do, or die job: positioning the weld-on portion. We fitted it several times, then marked the position with a felt pen on the bottom frame rail. Then I loosened the lift clamp, strapped, and rolled the bike over toward the primary side with a strap, until I had it positioned at just the correct angle. This is always a trick. Too far adds dangerous weight to the kickstand and makes the bike awkward to maneuver. If the bike sets too upright, it’s iffy to park, and as with my Shovelhead, I can’t park it in many positions. It wants to pop over. Even the wind can push it over.

With all the touchy elements considered I positioned the Mr. Lucky kickstand against the frame, and folded it up to see how it fit in the running position. It ran smack into the mid controls system, so I adjusted, and we are thinking about running a piece of hose, or even shrink wrap up the kickstand arm to prevent vibration.

With the bike leaned and the arm in the extended position I made two guide marks on the weld-on portion and on the frame rail. Then I could straighten the bike for tacking. I tacked the weld-on bung on both ends, and then tested the position against the straps. Then I ran a bead along both sides with my MIG welder. I plan to double up on the welds with the TIG, once we pull the bike apart.

We were cranking along, but had to step back to my Mudflap girl bike, since the shocks faded and we needed 1-inch longer shocks. We had to pull them apart and add to the bumpers so that the fender would not hit the tire. Progressive has various bumper lengths. The key here is to dismantle the shock, install them, lower the bike until it hits the fender, and make a bumper measurement. Progressive makes hard plastic bumpers in various thicknesses. We made a special tool, used a drill press, and took the shocks apart several times, until we had them dialed in. The key when measuring for shock length is to consider about 1-inch of fade once the shock is installed. We shifted back from a 12-inch shock to 13-inch Progressives.

So, my Mudflap baby was hauled to Saddlemen for the gurus of seats to evaluate. I’ve toured many companies over the years, and the Saddlemen operation is impressive. I met guys who have been making seats for 25 years, and their sons are now working with them. It’s truly a family of operators. They’re very involved in an ongoing hunt for the perfect seat technology. First, they studied foams, and then gels, and now this new design that affords a buffer area to relieve pressure on the spine. We discussed styling and design. Then we peeled out to let the masters consider the options.

We faced an open warm, clear, SoCal day and jammed back into the shop. I started by installing the Biker’s Choice regulator bracket and the Spyke regulator into position. Ray turned to install the S&S carb, since we were faced with the opportunity to install and complete the Crane cam and lifter system. Most Crane products are manufactured by S&S, including their roller rockers for twin cams.

We discovered a crazy tough oil cooler system from Baker Precision, on Signal Hill, and I tacked studs into place on the front frame rails. It’s made in Canada for automotive power steering oil cooling applications. After we installed the belt, we discovered a problem with the rear fender and the belt slot. The fender needed to be removed and reshaped. I also needed to develop a rear brake anchor.

That was the day Buster came by and we decided to go for a ride. I crashed, returned to the shop bruised, but the Shovel kept running. I thought about kicking back and watching Sunday night football, but I needed to pause it, and jammed back to the shop to keep the program rolling on Frank’s bike. While Ray installed the S&S Super E carburetor, I removed the rear wheel, the rear fender, cut a new slot in it, and drilled a hole where the Choppers Inc. Mudflap Girl taillight stem hit the fender.

So here’s the snafu. It surfaced the last time Frank came over. “I didn’t want mid controls,” Frank said. “I wanted forward controls. It’s all your fault.”

In the next segment, we will deal with his changing desires–kids. Then we’ll fire his bike, with the ACE grip wiring system to lead the way.

Sources:

Spitfire

Biker’s Choice

JIMS Machine

MetalSport

BDL/GMA

Wire Plus

Branch O’Keefe

Bennett’s Performance

Custom Cycle Engineering

Saddlemen

Bub

S&S

Mr. Lucky

Bikernet/Cycle Source Sweeps build part 2, Sponsored by Xpress

By Robin Technologies |

Hang on for a chance to win this bike. The odds will be terrific, so step up and enter, or subscribe to Bandit’s Cantina on Bikernet.com, or Cycle Source Magazine, and we will take care of your entry into the drawing towards the end of the year. In the meantime, grab a beer and enjoy this build process monthly on Bikernet, or on the crumpled pages of Cycle Source magazine.

Last issue, we discussed the myriad of top-notch components flying at this build, and how Jason built the frame, at Texas Frame Works, around the master’s configuration and the pre-bent contoured backbone. The master is the boss of the 28-year- old shop, Kustoms Inc. and Evil Engineering, Gary Maurer.

Gary recently took possession of the Texas Frame Works rigid frame, the magnificent Crazy Horse 100-inch engine, the Baker transmission, Accel electronics, and of course, an Evil primary drive system.

“I like to design the sheet metal and frame around the complete drive line,” Gary said. He has a build theory based on the major components in place during the frame and sheet metal design process.

This time, the frame was built behind his configuration, then in went the engine and trans, so he could design sheet metal befitting the lines of the frame and make it cup the engine and trans. He asked Jason to stretch the frame to allow him the space to install the battery behind the trans and in front of the fender.

“I like to build bikes with the battery under the transmission,” Gary said, “but they’re a bastard to work on.”

In this case, the bike will be built as an everyday rider, so ease of maintenance is a major consideration. Here’s the twist of the month, and a major element in the formula behind Kustoms Inc’s success. Gary opened his shop in 1982 as a part-time endeavor. He was 22 at the time, and shortly after, he kicked it up to full-time in 1983. About that time, a 16-year-old high school sweetheart wandered into the shop and enjoyed the vibe. Julie Gilford started answering the phone. Her family taught her work ethics and didn’t allow her to sit around on her cute ass.

Gary made most of his cash flow by repairing and painting Grand Ledge Post Office Jeeps and building race cars. Since the shop consisted of Gary and usually just one helper, Julie picked up tools, cleaned the shop, then started to perform mechanical duties. In 1985, Julie graduated from Grand Ledge High School, and Gary dodged child-endangerment charges.

Julie grew into a major fabrication team member within the tight Kustoms Inc. crew. She built frame tables, fabrication jigs, and runs the mill with her long deep brunette hair pulled into a tight bun. “If she took on welding and running the lathe, I would be out of a job,” Gary said humbly. They have worked together for 28 years so far, and she rides. Three years ago, she hit a deer, but that’s a harried tale for another time.

So Julie jumped at the chance to dig in on the first fabrication build project for the Bikernet/Cycle Source Sweepstakes build, the oil tank. Kustoms Inc. offers several hand-built oil bags. They manufacture a couple of sizes in a donut configuration, with a hole down the center. They also offer a couple of sizes in this oval shape. Julie cuts out the end plates and then forms the oblong, barrel-like exterior. Gary machined mounting bungs using stock Harley gas tank rubber mounts to fasten the oil bag to the frame securely.

Julie drilled the holes in the tank for mounting bungs and oil line fittings. Gary ran the feed line to one end, the return line at the other end, and the vent line near the filler cap. They also drilled and positioned the drain cap bung and the filler cap bung.

After building precision racecars for a couple of decades, fabricating custom motorcycles is all about fun. “At one time, I had to hide my motorcycles when the car guys showed up,” Gary said. “Now the car guys want a chopper to match their racecar.”

Sure, bikes have always been the bottom rung, low-class outlaws. It never changes.

Don’t miss the next episode. They bought a set of ’90s, 3.5 gallon, H-D fatbob gas tanks. Julie will form the pieces to eliminate the dash dish and make them pure flat-sided tanks. Gary will mount them on either side of the frame so the frame will be visible down the center.

“This bike will be built to ride, but look cool,” Gary said.

Don’t miss the next episode, or a chance to win this puppy.

Sources:

Xpress

http://mysmartcup.com/

Crazy Horse

http://www.crazyhorsemotorcycles.com/

Kustoms Inc.

KustomsInc@hotmail.com

Fab Kevin

http://www.fabkevin.com/home.htm

Evil Engineering

www.evil-engineering.com

D&D Exhaust

http://www.danddexhaust.com/

Wire Plus

http://www.wire-plus.com/

Barnett

Barnettclutches.com

Shorai Batteries

www.Shoraipower.com

Bell

www.moto@rcn.com

The Amazing Shrunken FXR Project Part 3

By Robin Technologies |

Bandit and I were checking out the Amazing Shrunken FXR. “Thedamned thing,” referring to the shrunken FXR project we had beenhammering at, off and on, for almost two years, “has attitude,” hegrowled, “a bad-assed attitude.”

“Yeah, but will it have sound attitude?” I mused. “I want it toget attention. I want it to be felt in their chests before they seeit. I want them to hide their children from the evil they fear.”

The Amazing Shrunken FXR has developed into a mythic ethos. Froma cardboard box full of rejected, beat-up, and cast off parts, thebike has become a sculptured icon, a physical dream, and perhaps awrong turn down a bad dirt road, three miles back.The project began back in the spring of 2001. After a lot of fitsand starts, the Buell Project, the Sturgis Run, the Deer Gut stewadventure, Bandit’s painful recovery, the Red Ball prep, variousevents including a trip around the world and soiree’s, we slappedparts on, hammered steel into shape, welded this and that, cussed andfarted and got to where we are with the help of a RevTech driveline,Custom Chrome, BDL belt, Joker controls, Cyril Huze sheet metal andCompu-Fire electrics. The bike is raw boned, trimmed down, and meanlooking. That’s where it stands, inert and waiting for inspiration,up on the rack at the Bikernet garage.

Bandit regarded the raw metal frame with squinty-eyed intensity.”What you thinkin’,” I asked, keeping my own gaze focused on thepotential of the bike. At my question he stretched out his gangly,egret-like frame to its full 6’5″. “It’ll be a loud mother fuckereither way you play it,” he intoned in his gravitas basso-profundodeep voice. “We’ve shortened the frame and rear wheel base so muchthat it’s barely a cunt-hair from the exhaust port to the rear wheel.”

We cut a piece of an Samson Evolution system with a Mikita touse the exhaust port, then started welding other pieces in place. Wecut it back to make a tight turn and create space away from the oiltank.

“Fuck it,” I responded in my best Pancho Sanchezimprovisation, “let’s just start from the port and see what happens.”

We rummaged through a pile of Samson scrap exhaust pipes that wehad scavenged from a dumpster behind the Sampson factory. Flingingout fish tail tips, shot gun systems and swoopy cruiser exhausts,most of them dented and damaged so they couldn’t be re-used. Mr.Samson gave us only the best to modify. We eventually came up withenough pieces to fabricate a Frankenstein exhaust system.

As I grabbed for a section 1 3/4-inch chrome pipe, Imistakenly grabbed a goodly chunk of fur. Bandit’s midget, crazeddemon of a feral cat yeowled in protest and sank his needle-liketeeth into the back of my hand.

“God damn that crazy bastard,” I screamed, “he’s as crazyas a peach orchard boar.” I’m sure Bandit has a mescaline salt-lickfor that freaked out feline.After I extricated my hand from the jaws of Bandit’s feline Cujo, Ireturned to the exhaust system at hand.

Our intent was to minimize the exhaust system as much as possible.We ran the pipe straight down from the front exhaust port, thenturned it to hug the bottom of the engine case. We had originallyhoped to put a flattened pipe under the frame, but reasonable roadclearance dictated a different path. So we tucked it in and aroundthe engine case, then inside the frame, coming out just at the edgeof the back wheel.

“Our first mistake,” Bandit spouted, “we needed a smallerdiameter chunk of exhaust to form guides when welding chunks ofexhaust together. If we had slipped it in one piece even a quarter ofan inch. it would have held each chunk in alignment. That’s onetheory to building pipes. The key to fabing your own pipes is havingenough scrap to slice and dice, then cutting and working each pieceuntil it’s as close to a perfect fit as possible. Finally the tackingprocess is critical. That’s were the guides didn’t come in. If we hadguides we wouldn’t have offset pipes tacked into place. That problememerged severely a week later during the grinding process.”

“It took two days of playing, cutting, fitting and welding toform a completely custom exhaust system in place,” Bandit added.”Make sure you wet towels and form a fire barrior around your tackingarea to protect the rest of the bike. I used a small 0-sized torchtip and common hanger to tack the segments of pipes together. I’m notconfident enough with our new MIG welder with thin sheet metal, so Istuck with the torch.”

” It wasn’t perfect, but it was ours,” Bandit added, “acompletely unique system that would be tucked under the transmissionand attached to the driveline solidly under the tranny backing place.Then we faced the muffler aspect. The pipes were too short to be openor we would have been arrested within a block of the headquarters.”

Needing some kind of ‘standardized’ muffler elements, we went toour local San Pedro Kragen Auto Parts store. With the clamp-on piecein hand, we found parts and pieces enough to create a 7″ mufflercase. “Most of the elements were too heavy and glass packed,” Banditspouted, “We couldn’t weld on a glass pack.”

Back at the garage, with torch in hand, Bandit cut out a sectionof baffles from some scrap Sampson muffler. Spot welding the bafflesinto our jury-rigged muffler, we produced something that may, likeJapanese Fart Wax, diminish the painful ‘Brap-rap-rap’ flutter ofunrestrained exhaust back pressure. A right-angle turn-out willdirect the dragon’s breath exhaust from the screaming 88cc Rev Tech,high-performance engine to an unsuspecting public standingslack-jawed and terrified at the curbed edge of civilization, theirhair-dos blasted straight by the sizzling after-burner of the AmazingShrunken FXR.

“He gets sorta twisted,” Bandit muttered shaking his head.”Actually with the baffle in hand we went to San Pedro Muffler Shopand looked at the myriad of tips and tubing alterations we couldmake. We found a tip and had a chunk of 1 7/8 tubing spread to matchthe tip. That formed the other end of the muffler. We just had toweld the three elements together.”

I welded the baffle in place, positioned as it was in theSamson System. I discovered that the two elements didn’t want to weldtogether. I have a feeling the tip was made of an inferior metal.

With the die grinder we cut notches for the muffler clamp.

“After welding and fitting I stood back and was proud of ouruniquely tight system that would allow Giggie, from Compu-Fire, tomachine mid-controls for a final touch,” Bandit interupted. Theexhaust played perfectly into the Shrunken aspects of the project. Iremoved the tacked system and began hours of gas welding to make itwhole. That’s when all hell broke loose. While working on anotheraspect of the bike with my back turned to my partner, he began togrind the welds. The college art history professor sought perfectionwith each weld and ground right through the thin walls of the18-guage exhaust pipes. It was amazing. I was sure the system wasruined.”

This shows the amount of area ground down so far we were forcedto fill it or destroy the system and start over.

“Some builders tack systems together then take them tomuffler shops for professional construction. I thought that was mynext move. Unfortunately a regular muffler shop doesn’t have themandrels to make the tight bends we had proposed. I was devastated,but the man told me that he could fill the welds with his MIG welder.

More welds to fill the mad grinder’s cutting work.

“Unfortunately each weld was now a 1/2 inch tall and wide zit atalmost each junction of the pipe. Nuttboy began the grinding processagain. More holes were found and I filled them with gas welding usinghanger rods. I joke now that if the bike runs like shit we blame iton the exhaust system. If it runs well, it’s the same roll of thedice. We’ll see.”

“Making your own exhaust system can be a blast, just don’tget heavey handed with the grinders. Pipe is thin and a little weldthat shows won’t matter much since we didn’t plan on chrome, butblack Jet Hot coating. I’ve sworn off chrome exhaust systems on mybikes for the future.”

That big bastard just won’t shut up. The next episode in thismechanical adventure will feature Giggy’s attempt a electrifying thesteel monster. Next weekend, barring any new bike projects, Giggy’sinopportune finger damage at the power tools, splattered deer guts,San Pedro political insurrection, Sin Wu’s beguiling charms, a caseof beer, or any other form of diversion or chaos, we will be closerto cranking this monster over.

To Continue……..

Back to Part 2……..

Back to Custom Chrome on Bikernet……..

Back to Joker Machine on Bikernet……..

Road King 4/15/09

By Robin Technologies |

We decided to take a run at an electrical article, since about 90 percent of problems and breakdowns come from the electrical component. Besides, it’s riding season and we all need to check our electrical connections before we ride off into the sunset. This is especially true of bikes stored in moist or seaside climates. Besides, I’m riding the King to Laughlin and need to check it out. It’s been awhile. Here’s the lastest upgrade to the king: King Meets Zippers and D&D

This article will cover some basic electrical checks, since being forced to charge your battery indicates deficiencies in your charging, or wiring system–or you left the goddamn lights on.

This rambling will also cover all the aspects of the latest battery charger from Biker’s Choice, the Xtreme 12-Volt battery maintenance charger. If you find it necessary to charge your battery, take it out of the bike and place in on a wood or fabric surface, not steel or concrete (draws battery charge). Make sure the terminals are clean. A loose or corroded terminal will prevent the battery from accepting a charge. No shit, just that will leave you along side the road.

Corrosion, or bad grounds cause most electrical problems, especially in dense humidity climates. Check your grounds annually; clean the connectors and the ground surface.

Batteries are nasty dangerous bastards. Make sure to protect yourself around them. Don’t mess with a battery near flame, extreme heat or next to your custom painted Ferrari. If the bastard explodes, you could lose your eyesight and that $5,000 paint job. And that acid crap is super nasty. Don’t get it on anything. There is a cure. Mix some baking soda and water and have it standing by to clean anything with battery acid splashed on it. This is no jive. If you get battery acid on anything, it’s toast. Believe me. I have a number of holy shirts from acid meetings.

Wear eye protection and don’t fuckin’ smoke around batteries. Fortunately, for incased batteries, we don’t have to mess with acid as much anymore, but I’m still building choppers and using bullshit little batteries with acid requirements. Whatta mess. Make sure the area used for charging is clean and well ventilated. Okay, enough for the safety procedures. The Xtreme Charger comes with complete safety warnings.

For years I liked Battery Tenders, because they monitored the charging process and dropped the charge level automatically, when the battery was completely charges. If the charge level dropped, the automatically kick into gear again. This Xtreme charge handles those tasks and more to keep your battery strong and charged. Below is the full description of the Xtreme capabilities. The kits also come with a lead set you can bolt directly to the battery for easy access at anytime. Check this out, then we’ll give you some testing, trouble shooting electrical tips:

The Xtreme Charge is ideally suited for AGM and Maintenance-Free Batteries. The combination of PulseTech’s patented pulse technology and proprietary charging algorithm allows it to charge these high-performance batteries more fully while maintaining a safe charge profile for traditional batteries.

The Xtreme Charge Battery Maintenance charger comes in variety of colors, which may suite a particular need. If your looking for the best battery maintenance charger for use on any 12v battery rated from under 10Ah to over 150Ah, pick your color, and get one today.Includes fuse-protected quick-disconnect battery clamps and lugs, Important Safety Instructions and Quick-Start Guide. The Xtreme Charge is fuse-protected, spark-proof, and is UL and CE certified.

Comes with a Five-Year Warranty

Xtreme Charge Maintenance and Charging

The Xtreme Charge is a microprocessor controlled maintenance and bulk charger for any type of 12-V lead-acid battery. It features PulseTech’s intelligent circuitry, which imposes only the correct amount of charge rate as determined by the continual evaluation of the battery’s condition. By using only the appropriate amount of charge rate, the battery is maintained safely at its proper operating voltage indefinitely. Conversely, if the charger is connected to a discharged battery, its bulk charge capability (2.5A actual/5A effective) will re-charge the battery rapidly and safely so it can be put back into service quickly. Charge rates may be as minimal as 0.2A during typical float up to the full 2.5A for more deeply discharged batteries. This variable float charge ensures optimal charge rate is applied to the battery at all times.

PulseTech’s unique and patented PULSE technology increases the duty and life cycles of your battery by minimizing the size of the lead sulfate crystals. This allows a battery to accept as much charge as possible. PULSE technology helps ensure that your new batteries will stay in like-new condition while improving older batteries dramatically. Duty cycles are typically extended from three to five times for all types of lead-acid batteries!

PulseTech’s ReNew-It Pulse Technology

Twelve years ago, PulseTech applied its technology to a full line of innovative and unique products designed to make batteries stronger so they will work harder and last longer than ever before.

To get an idea of exactly how important PulseTech’s technology is to the performance of all your powersport toys, consider this: The main cause of vehicle failure is battery failure. The main cause of battery failure is sulfation buildup on the battery plates. And ReNew-IT Pulse Technology prevents sulfation buildup.

When it comes to a dead battery, chances are it is still good. You just can’t reach the energy due to sulfate buildup. That means you have to buy another battery even though the one you have may still be useable. Xtreme Charge helps prevent this problem.

How Renew-IT Pulse Technology Makes Batteries Stronger

PulseTech’s Xtreme Charge connects directly to the battery. The Xtreme Charge emits a pulsating DC current that removes the sulfate deposits from the plates and returns them to the battery acid as active electrolyte.

Here is how it works:

1. Lead-Acid batteries work by releasing energy through an interaction that occurs between the positive and negative lead plates and the lead sulfates in the electrolyte.

2, Sulfation buildup occurs as lead sulfates form on the battery plates during the normal charge/discharge cycles. During this process, some of the sulfates enlarge to the point where they won’t accept energy so they stay on the plate. Over time these sulfates can build up until efficiency is reduced and finally the battery dies.

3. ReNew-IT Pulse Technology works to prevent sulfation buildup by removing the sulfate deposits from the plates through a unique Ion Transfer process.

4. The lead sulfates then return to the battery acid as active electrolyte. When connected on a regular basis, our battery maintenance systems will also keep the sulfates from building up again.

Get True Battery Power

PulseTech’s technology works with all types of lead-acid batteries including sealed, gel cell & AGM. By keeping the plates “clean”, batteries charge faster and deeper so they work harder and last longer than you ever thought possible. They also have greater charge acceptance so your battery will recharge faster and release all of its stored energy. With more available energy so your vehicles last longer between recharges and your electronic accessories work better. You get the true power of your batteries.

Some of our patented products also prevent the normal loss of battery power on stored vehicles and equipment no matter how long they sit unused—even months at a time.

They even help protect the environment. Since batteries last longer, it reduces the danger of contamination caused by lead and sulfuric acid dumped from prematurely discarded batteries.

Xtreme Charge 5 Stages of Charging

1. Initialization: Xtreme Charge’s unique test feature evaluates the battery thoroughly during initial connection to determine the appropriate charge rate based on its size and condition. It tests the battery continually for as long as it its connected to the charger to maintain the optimal bulk or float charge rate. This test step incorporates a “Bad Battery” indication if it determines the battery is faulty and can not be charged.

2. Saturation: A proprietary computer-integrated technology measures both the voltage and current to determine the appropriate amount of charge the battery is able to accept at any given time. As the pulse and saturation charges improve the battery’s condition, the charge rate is increased safely to an optimal level. This proprietary algorithm protects the battery from the risk of damage due to overcharging.

3. Storage(Float)

4. Pulse(De-Sulfation)

Testing Tips

I reached into a couple of Harley manuals and to Pablo, our Bikernet Harley factory trained technician for additional info. If you suspect a problem with your charging, you’re experiencing sparking when you hit the starter, or the battery needs to be charges, here’s some tips.

First, check all your grounds and battery posts for connection and cleanliness. Then take a voltmeter and run it across the batter whiled the bike is idling. It should indicate 12 volts (see chart). Now run the throttle up to about 2,500-3,000 rpms. The indication should jump above 14.1 volts, indicating that the charging system is working.

Before you toss the regulator and replace it, you need to check the connections with the alternator. Make sure you haven’t lost a ground or run over a speed bump and ripped through a wire running along the bottom of your frame, which is against the code of the west. Don’t run wires under frame rails. Keep them up and out of harms way.

To check the alternator, here are a couple of tips. Pablo suggests that you take an old regulator plug, with the wires and create a testing lead. If you check the resistance to ground on each lead, they should be open. “But if you take the derby off your primary and run into that burnt electrical smell,” Pablo said, “the alternator is toast.” There’s also an AC test. Start the bike and run it up to 3000 rpms. Attach your alligator clips to your alternator leads and it should read over 40 volts or 16-20 volts per 1000 rpms.

“With the newer models, we have seen some issues with the bikes having batteries going dead after a couple of days,” Pablo said. “A milliamp draw test and total current draw test is the first things you check in the H-D flow charts. Corrosion on the system relay on some models can cause this.”

“The service manual, including the electrical diagnostic manual are a must on the new models. You basically have to be a Circuit Head to work on these things nowadays. The H-D Digital Tech we use at the dealership also helps with the serious hard to find electrical gremlins.”

“Fuck, I’m just a old Seabee resistant to change. Man invented technology to frustrate himself you know. Just look at what we have done to a motorcycle over the years. Seriously though, one can, with a cheap DVM (Digital Volt Meter) do allot of trouble shooting on the H-D charging system. Like checking the stator for AC volts output. A grounded stator, continuity checks, etc.”

One more addition from Pablo: DC Voltage output at the battery with the bike running is also a quick check. The system should be putting out over 14 volts but not more than 15 volts at 3000 RPM. Usually, you will see like 14.1 to 14.4 volts or so, that is if the regulator is good and shunting excess voltage to ground.

So, with the Xtreme Charger and a volt meter, you can check your battery, the charging system, the alternator and check for bad grounds and busted wires. That’s all you’re gonna get from the Bikernet tech staff today. Let’s go to the Cantina for a beer.

Road King 1/7/04

By Robin Technologies |

I had a bad feeling about this mod. First, I don’t like to pack anyone, any time. If you want a ride on my Panhead, carry a hand-towel and a bungie cord. I avoid giving a girl a ride home from the bar, even a babe with gigantic hooters. I would preferred to follow her home. I’m not the kind of rider to take a woman on a long run. I would rather have a variety of women in various towns and cities. Okay, I’m a bastard.

Okay, so the pressure’s on. Sin Wu want’s to ride once in a while, and I want to get laid daily. Gotta give up something. I kept the stock Road King classic seat for additional passenger comfort. It’s covered with dust, in the corner, but that quick change aspect is covered. I ordered the custom billet tab for the rear of the stock seat, and had it powder coated black, so both seats were ride-ready. When you purchase a new saddle, it doesn’t always come with the rear tab. The base is plastic and screwing fasteners in and out will wear out the threads.

Here’s a handful of the fasteners and bag bracket spacers.

I ordered the front and rear detachable docking hardware kits, but be careful. I leaned toward the new lower backrest/sissybar for styling, which wasn’t in stock, but the pad was. I bought it, then the backrest was back-ordered so we bought the taller sissybar for immediate gratification, but when we got home the pad didn’t fit and we were forced to buy the tall pad. Watch out for this dilemma when ordering. Make sure to check all the installation instructions to make sure you have the correct puzzle pieces. There are several back rest options so watch that aspect when ordering.

Here’s the massive chromed Classic H-D axle dress hardware.

This is simple installation. Slip on the plastic wedge and the cap grips over it. Push them into place–done deal.

We also ordered some classic hex bolt covers and stainless Allen caps to begin an engine detailing process. We purchased chrome caps to detail the front brake calipers and classic chromed front axle covers. We didn’t use the plastic chrome caps ultimately but brush painted the raised edge of the calipers black. I’ll tell you why in a bit.

This was supposed to be one of the easiest mods we undertook, but we learned quickly, that wasn’t the case.

This is the front docking port in place, but not tightened.

When we black powdered a ton of components previously, we assembled the bike securely with Loctite and care. That was our undoing. The Phillips-head beside the shock needed to be replaced with the front docking hardware. Take one bolt out and replace it–no problem, right? The Phillips screws wouldn’t budge and we proceeded to strip the heads. First, I wished I had an impact driver.

I discovered an aerosol spray by Chemsearch called Yield in the auto parts store that loosens rusted bolts instantly. It worked like a charm, with a little patience the bolts came lose. An American Rider reader complained that this product isn’t available in retail stores. That’s true. My longshoreman connection hooked me up. You may need to find a factory worker or mechanic who has a connection.

After reading the Low Detachable Backrest kit info that came with the taller kit, the Backrest Docking Hardware kit directions, the Front Docking Point kit instructions and the 100th Anniversary FLHT and FLHR Backrest Pad kit directions, I guzzled my first Corona.

I opened the next Corona. The operation would have been simple if the directions were. I read them over and over. There were too many variations between years and configurations to sort through. The Front Docking port directions confused me with illustrations involving rear bag support spacers designed to bounce out the saddlebags and clear the release button on the backrest.

This was a matter of trial and error.

If you’ve built choppers as long as I have, there’s always a way to make anything work, so ignoring the confusion, we spanked our asses in gear. I ignored the spacers, installed the front docking rubber that was designed specifically for the King with a notch for the shock.

There’s a bracket that runs from the front docking station to the rear, but first the rear docking port bracket needed to be installed. On some models equipped with air shocks the shock filler bracket must be removed. The directions said I didn’t need to remove it on the 2003, bullshit. It was directly in the path of the docking bracket, so off it came.

This shot shows the bracket in place, with the shock air port moved. Note the single empty hole in the bottom of the bracket. That’s where the rear bag mount bolts into place. The trick of the night.

Three lousy bolts had to be removed, the rear bag bracket 1/4-20 fastener and the two 5/16s fender support bolts. First the 1/4-20 spun the thin, tin clamp that holds the nut in place. Then the 5/16, once removed, could hardly be replaced. Nothing aligned properly. My lovely assistant had to squat and lift the tip of the fender, and in one case we were forced to remove the lower bag rail to align the top bolts.

This still doesn’t totally jive. Actually washers had to be fed behind the top Backrest mounting bracket also.

“Can I let go of the fender, now?” Sin Wu asked grunting. The top docking port bolts are packaged in two sizes, 1 inch and 3/4 inch. The directions warn that if the rear inch-bolt comes too close to the fender, replace it with the 3/4. We replaced both and used the 1-inch jobs in the front holes on both sides.

Without the rear fender rack detachable bracket, another option, two washers were thrust under the rear docking port bracket to make up for the thickness of the rack bracket.

Part of the confusion was the numerous detachable elements available for various models. There’s also the two-up detachable rack front docking kit that surfaced from time to time.

That’s all there was to it. We bolted all the elements in place and tested the back rest and bags. Sure enough the King Classic bag lid smacked into the backrest latch when opening. We ultimately spaced the rear back bracket out only about an 1/8 of an inch and we were good to go.

We tried it with the spacers, without, then with smaller spacers that worked perfectly.

Sin fed me chips and salsa and dabbed my sweating forehead with a bandanna, while I slipped the saddlebag bracket, 1/4-20 nut, into place using a long magnet. It worked on the right side. On the left we unbolted the entire fender support, replace the nut, adjusted the thin, tin tabs, and bolted the sucker all back together, only to have the nut fall out again. In this case we squeezed a slim square 1/4-20 nut behind the docking bracket and bolted the back bag bracket on with a spacer. It worked like a charm.

“Can we ride?” Sin cooed. I told her to gear up. We were just about ready to roll.

I used electrical contact cleaner to loosen the tin insignia plate, but discovered that wasn’t the intended plan. Leave it be, goddamnit.

Here’s the totally clean caliper. Big mistake.

I ground the lip unevenly, but it then fit into the recessed slot on the caliper.

After grinding, all was well. Sorta.

The air in the garage eased as I warmed to her company. For an easy half-hour we played with the details of the bike by installing nut caps and front axle caps which I snugged down against a coating of silicon to prevent vibration.

Some silicone on the axle nut will prevent vibration that may loosen the cap.

I discovered that the front chrome caliper caps stuck directly against the existing tin insignia. I took one off and cleaned the area thoroughly with electrical cleaner then the self-sticking surface didn’t reach the base.

Here’s the 100th Anniversary backrest that will not fit on the short back rest bracket. We sent the short unit to Custom Powder Coating, in Dallas, for a coating of black.

Note that there are various pads and various fasteners and spacers for different applications. Don’t try using common sense.

I ended up with 1/2 pint can of Rust-oleum paint and a small brush for touch-up details. I sent Sin Wu in the house to prepare for the ride. That meant striping out of her threads and waiting for me in bed. It’s the code. We must workout before we ride.

–Bandit

Editor’s note: I’m sniveling through this, but I’m sure with some experience this would have been a breeze. I suppose that’s what dealerships are for.

Sturgis 2001 Part 2

By Robin Technologies |

Here’s a couple of shots of the Bikernet Street FightingBuell for Sturgis 2001. This is how it currently stands with ahandfull of minor modifications and a lot of plastic removed. Let meknow what you think.

Note the pulley guard. We had the notion to take levers andbraces like this off, lightening-drill polish and replace. Not sureif that’s going to be the bit, now, but this brace was the test. Ithink we’ll powdercoat rather than polish.

Trying to keep polishedaluminum up on a bike that’s well ridden is a pain in the ass. Haveyou seen a polished engine after a ride to Sturgis? We plan to removethe triple trees and swingarm. The tabs for the plastic dust shieldsneed to be removed and then the parts need to be polished to removethe ribs and casting marks before we decide on a finish.

Let us know what you think. I think I should black powercoatthe swingarm and maybe the trees and lower legs. We’re looking for apainter for the sheetmetal, and we’ll be ready to rock.

–Bandit