Goliath CCI Bike Kit Build

By Robin Technologies |

It was hard to imagine, when we stood in front of the garage doors, starring at a pile of boxes, that somewhere in there, somehow, a custom bike lurked. As it developed, except for a non-existent nut or bolt, the CCI Goliath kit was complete. The chromed quandary, could a novice builder, an average American rider (in this case a bumbling college art professor with limited mechanical experience), Ladd Terry, build a hard running 100-inch custom in a week to ten days?

Not just any cruiser, because the components that make up this rolling mechanical architecture scream “modified custom.” It starts with a solid foundation, including the potent RevTech 100-cubic-inch engine, a six-speed overdrive transmission and a Santee 230/250 frame made from 1-1/8-inch tubing. The engine has a two-year/20,000-mile warranty, and the gearbox is covered for 5 years or 50,000 miles. There’s another side to this powder-coated and pearlescent picture. The sheer enjoyment of being able to build your own bike. “It couldn’t be more educational and rewarding,” Ladd said listening to the sharp exhaust crack against the Bikernet.com Headquarters concrete. “What a blast.”

Other components are also top-notch. The 18-inch rear wheel measures a full 8.5-inch wide and is made from solid billet. An 11-inch-wide steel rear fender with streamlined struts covers the Avon 250 rear tire. Billet RevTech brakes grace both ends with clear-coated stainless braided brake lines. Tall 8-inch Custom Cycle Engineering risers securely hold powder coated TT bars that sit atop the smooth billet triple trees, holding 41mm front tubes. A billet dash housing a VDO speedometer adorns the six-gallon Fat Bob tank. The hand controls are CCI chromed, the foot controls are chromed billet. The chain primary drive was enclosed for quiet and smooth operation. Gleaming chrome hangs everywhere. And the complete electrical system includes a high-torque starter and 32-amp charging.

“It ain’t all about parts,” Ladd added, “It’s the experience, the rush of being able to build a tough performance cycle, and I need to congratulate the CCI crew for their organizational capabilities. I couldn’t have completed the task without them or the Tim Remus book on building kit bikes.”

“Hold on,” Ladd snapped as George Hayward, the benefactor for this Beach Ride Charity effort, dropped the clutch to peel out of the garage, “I want to add something.” A college professor always requests the final dissertation. “Even though this was a kit that could be followed to the letter, it allows the builders creative avenues to pursue.” We did, ultimately, build a one of a kind custom with the paint work, exchanging bars and risers, modifying the exhaust and fender rails, changing the pulley and additional small touches to make this ride an American Rider’s creation.

Not bad for a tight team with hand tools and the desire to build a unique machine for a children’s charity, the Exceptional Children’s Foundation in Los Angeles.

Bandit 2006 Sturgis Shovel

By Robin Technologies |

Editor's Note: You've seen the “American Iron” feature. Chris Maida, the editor, asked us to reshoot it, but we kept the original shots near the Wilmington, Califa, Port of Los Angeles rail road tracks. Just happened that a train rolled past in the middle of the shoot. Enjoy.–Bandit

I just did the Old School bit and rode this bike to Sturgis on our Bikernet.com 2005 run from the West Coast.

I cottoned to the pure machine marquee. I didn’t plan to paint it at all, unless absolutely necessary. I wanted to leave most components unblemished metals and incorporate as many iron types (for color) into the mix as possible. I wanted this mess to contain brass, copper, aluminum, steel, and stainless. Of course the steel corrosion dilemma dictated that we use some powder coating for a protective seal. The front end came in black to avoid chrome, so I supplemented the bike with a few additional black pieces, but the frame and some others were powdered to mimic a copper patina. Some aluminum parts were clear coated to prevent complete dulling and afford an acceptable pin striping surface. Some brushwork was applied.

It started with a Shovel engine that a brother gave me with a title. I loaned him a bike when he was down. Due to family illness he was forced to sell everything. There’s nothing better than an engine with a title. I took it from there and ordered a Paughco classic frame to fit me and handle like a midnight dream. Too many choppers today look good but don’t handle worth a damn. I wanted a bike to fit, handle well on freeways, yet be light in city traffic and parking lots. I spoke to Ron Paugh at Paughco and they built me a 4-inch up, 3-inch out, 35-degree raked rigid, wide enough to handle a 180 tire.

I don’t care for wide tire, fat-assed, beachball monsters. I decided to set my limit at 180 and run an O-ring chain for the traditional look. I stuck with a Paughco front end to top off the chassis. It’s one of their new tapered leg springers, 9-inches over with three degrees of rake in the trees. It worked out to be almost 5 inches of trail and handled as light as a dirt bike.

The engine had early stock heads, House of Horsepower cases and was a 105-inch stroker, too much for a rigid chassis. I wanted this bike to last, be a beater, but not be a dog. I contacted friends at S&S and they suggested 93 inches of street power for a balanced, reliable drive train. The stroke was reduced to 4.5 inch with 3 5/8 inch bore. The bike is fast but not a vibrating monster. I also spoke to Lee Chaffin at Mikuni and he suggested a 42mm, flat slide, Mikuni carb. “It will give you sharp throttle response,” he said. If I planned to run the Shovel on the salt flats he would have suggested a 45 mm venturi.

I have a couple of codes when it comes to building choppers. I like to keep them as simple as possible. On the other hand I like an oil cooler and filter to keep the drive train alive. I came across a system that bolted to the front motormount and doubled as a cooler while holding a spin-on filter (Rohm billet oil cooler mount). It was perfect. Other chopper codes include having enough taillight to prevent being run-over and enough gas to take you 100 miles before you hit reserve, or you’re looking for gas stations constantly. In this case I nearly broke the code a couple of times.

The Sportster gas tank originated on the verge of being beneath the acceptable fuel capacity, 1.75 gallons. It was an old Aluminum XR 750 race tank that we heavily modified. Get this: Some aluminum tanks are against the code, they’re too weak, notorious leakers. I broke the unwritten rule because it was a factory tank—cool right? Not so. “They broke during flat track races,” Berry Wardlaw, the Boss of Accurate Engineering, said at dinner in Deadwood, South Dakota, after I welded it twice on the way to Sturgis. “They ain’t worth the powder to blow ‘em to hell.”

I put more work into that tank than the Martin Brothers pour into a set of one-off artistic sheet metal. First I added additional rubber mounted bungs to the base of the tank for added support, since I didn’t on the last Sturgis rigid. It broke twice. Because the tank would reside on a severe angle we moved the petcock to the rear, also for more fuel capacity. We drilled the tunnel and welded in a plate to allow the entire center section to augment petrol storage. Then I installed a Crime Scene speedster cap for an old school hot rod appearance.

Kent from lucky Devil Metal Works in Houston supported the aluminum theme by hand fabricating an aluminum fender to match the tank, front and rear. We scrapped the front job.

Back to the code. Remember the taillights, so a semi will at least recognize that it’s a motorcycle under his rip-roaring wheels. This is a tough one for me. I like the minimalist approach, but endeavor for some level of survival. The crew at Eye Candy Custom Cycles (.com) developed this hot looking, side-mount ’59 Cadillac taillight. I thought it was the cat’s paw and that I could mount it to glow through to both sides. I installed it to the BDL inner primary, so close and tight to the frame that no one could see it. I broke the code.

I also grappled with some elements of the wiring, but it worked out fine—that’s another story. I’ve been tinkering with bikes for 30 years, yet learned a tremendous amount with this build.

The bike continued to roll together like a dream with the Kraft Tech oil bag, hard copper oil lines, the Lucky Devil sprung seat and 5-speed Rev Tech Transmission. The wheels were Custom Chrome aluminum rims, stainless spokes and chromed steel hubs. This was the first time I ever used Brembo brakes, no problem and I’ve worked with Joker Machine controls for the last five years.

Let’s focus on mistakes I made, so you won’t make them in the future. The hard lines were cool, but I could have installed rubber hose and been finished in a half hour. Plus, since the Kraft Tech, round oil bag, was rubber mounted and the hard lines solid, the street vibration fucked with them and they cracked. I needed vibration resistant furrels. Let’s stick with the oil bag. It’s cool, solid and bolted right up, but battery choice is critical. There was very little space between the battery terminals and the frame. Ultimately, a Bikernet babe was called to the front, to stitch a rubber protective cushion to prevent shorts. That’s too close for everyday comfort.

I broke in the bike using the Eddie Trotta formula for success, but missed one element, high-speed interstate travel. If I had put a few miles on the bike at 80 mph, which is against the break-in code, of 55 or less, I would have noticed the severe gearing. That’s where I went wrong. I started with a JIMS 6-speed and stock gearing. Then I discovered that the new Starter system from Compufire, that runs off the engine, wouldn’t be available for Sturgis, so I had to punt. I mounted the Dyna coils under the oil tank, which prevented a standard Compu-fire starter from being installed quick. A kicker was the answer. It fit with my hand made exhaust system using modified Samson mufflers, but I was forced to shift back to a Rev Tech 5-Speed transmission, because I needed the kicker. I should have considered a gear change at that point, but didn’t.

So what happened on the 1500-mile trek to the Badlands? The bike ran like a raped ape, strong and true. The handling was superb, everything remained in place except for the bullshit running lights I attempted to use for more visibility. They vibrated, spun, popped the bulbs and tore at the wires running through the fender rails. The ragged glitch in the road was the gearing. I ultimately replaced the running lights with these no-count reflectors and a H-D teardrop turnsignal under the right muffler.

The bike clocked 300 miles before I left town. Another 200 miles down the road toward Arizona, it had the mileage numbers to afford me enough break-in miles to drop the hammer and let her fly. At 90 mph I peeled past big rigs on Interstate10 heading out of the vast Los Angeles plague of concrete and stucco homes reaching dangerously close to the Arizona border. Crossing the state line, into the helmet-free state, I felt relieved to experience 100 degrees in the open desert flying toward Phoenix, another blight of concrete and southwestern architecture. I sensed the buzz in the frame and handlebar grips through Custom Cycle Engineering rubber mounted risers. The Shovel was over-revving and I needed that 6th gear release from extensive vibration, but I kept pushing for the love of speed, a light 520-pound, 93-inch chopper can deliver. She sliced the open road like a high-speed rotary knife through French bread.

I was beginning to buzz my feet off the Joker Machine pegs and adjusted them at the next stop. Rubber inserts on rigid pegs are mandatory, but I flaunted that rule with impunity. Just 60 miles out of Phoenix with the temps cresting 104 degrees and our group, of a half dozen, barreling along at over 90, the Sturgis Shovel quit, pure dead in the fast lane. I reached for the plug wires, then the ignition key that hovered less than a ½-inch from the whirling BDL belt drive. Better not go there, I thought as I signaled to lean right into the slow lane then onto the rough texture of the emergency lane where my baby came to a stop. That’s when I noticed the terrible, over-flowing gas leak at the back of the tank, all over the rear head.

As if the devil knew, one more mile and I would burst into flames in the middle of the searing desert. He flipped my ignition off. I never found an electrical problem or mechanical woe. She turned herself off because the vibration had taken its toll on the aluminum tank.

The next morning I was back on the road after Nick and Charlie at Custom Performance, (Turbo builders for Harleys, in Phoenix), had my tank rewelded and Nick recommended larger, softer rubber mounts. We were back on the road, where I took care of the beast for the rest of the run to Sturgis (kept my speed down), or until I could change the gearing. As it turned out, as I pulled into Deadwood, gas dripped onto that rear plug again. Bad news. There are codes and builders who know which ones can be broken—none. You can check the entire Sturgis Shovel Project build in our Bikernet Tech Department. The tank was repaired in Rapid City, but just two weeks ago I was forced to have it welded for the third time in Los Angeles. When will I learn?

Ride Forever,

–Bandit

Owner: K. Randall “Bandit” Ball

Home: Wilmington, California

Builder: Bikernet.com

Year/model: 1956 Sturgis Shovel

Time to Build: 9 months

Color: Shit brown

Engine/Transmission

Year/Model: 2005 S&S

Builder: Richard Kransler, Phil’s Speed Shop, and S&S

Displacement: 93 inches

Cases: House of Horsepower

Flywheels: S&S side-winder

Balancing: S&S, 1300 Bob weight

Connecting rods: S&S

Cylinders: S&S with longer skirts

Pistons: S&S forged, 8.2:1 compression

Heads: 1966 Shovelhead by Phil’s Speed

Cam: S&S

Valves: Black Diamond

Rockers: S&S rollers

Lifters: Custom Chrome

Pushrods: Custom Chrome

Carb: 42 mm Mikuni

Air Cleaner: Fantasy in Iron

Exhaust: Bandit and Samson

Ignition: Compu-fire, single fire

Charging: Compu-fire

Oil Pump: S&S

Transmission

Year/model: 2005 Rev Tech, 5-speed with kicker

Case: Rev Tech

Gears: Rev Tech

Clutch: BDL

Primary Drive: BDL open belt

Kick Starter: Rev Tech

Chassis

Frame: Paughco Chopper

Rake: 35 degrees

Stretch: 3-out, 4-up

Front Forks: Paughco tapered-leg springer

Swingarm: none

Rear shocks: nope

Front Wheel: 21-inch Custom Chrome

Rear Wheel: 18-inch Custom Chrome

Front Brake: Brembo Caliper and Springer Bracket

Rear Brake: Brembo Caliper and Softail Bracket

Front Tire: 21 Avon

Rear Tire: 18/180 Avon Venom

Rear Fender: Kent Weeks

Fender struts: Bandit

Headlight: Custom Chrome

Taillight: Eye Candy Custom Cycles

Fuel Tank: Aluminum 750 XR

Oil Tank: Kraft Tech

Handlebars: Custom Chrome narrowed

Risers: Custom Cycle Engineering dog bones

Seat: Lucky Devil Metal Works

License Bracket: Eye Candy Custom Cycles

Handlebar controls: Joker Machine

Foot Controls: Joker Machine

Witness Slips Needed Today

By Wayfarer |

|

|

Part 7 of VLXAFL5: Final Assembly Begins

By Wayfarer |

by Bandit with photos by Weed

The Paint Returned from TNT

It’s been awhile, but I haven’t dawdled. I’ve been working hard on various projects. That guy in Deadwood, who was once 45 John bought a 1960 Panhead roller/basket case and I’ve been helping with the reconstruction. I rebuilt or built and trans from a case and a sketchy box of parts. With Fab Kevin we built a front disc brake. John rebuilt the rear star hub and I helped with fitment and the rear brake.

We slid in the engine after I stumbled. I used the rear axle and a flat lift jack to jack up the bike, so I could block it, remove the jack and start to install the 5-speed trans in a 4-speed S&S case. The trans didn’t want to go so I filed and ground all the paint out of the 4-speed slots and the slot I made and welded for the 5th stud on the right. I even had to grind the rear tab on the trans case more for additional clearance.

I couldn’t run an old school 4-speed trans for a couple of reasons. It’s an alternator S&S engine and I wanted it to be electric start.

Click here for the accelerating Tech adventure with detailed photos and tips.

* * * *

Don’t stop there, we have a whole department on Motorcycle Tech since 1996. Click and build now!

https://www.bikernet.com/pages/Techs_Bike_Builds.aspx

Harley-Davidson’s 2024 Factory King of the Baggers Team

By Wayfarer |

HARLEY-DAVIDSON FACTORY RACE TEAM LAUNCHES FOR 2024 MOTOAMERICA MISSON KING OF THE BAGGERS RACING SERIES

18-Race Schedule Includes Round at Red Bull Grand Prix of The Americas

MILWAUKEE (February 16, 2024) – The Harley-Davidson® Factory Race Team today launches its 2024 season with an exciting video featuring team riders Kyle Wyman and James Rispoli aboard new race-prepared 2024 Harley-Davidson® Road Glide® motorcycles based on the all-new touring platform for the MotoAmerica Mission King Of The Baggers road racing series. The video, with exclusive behind-the-scenes footage of the team, dials up the fun and irreverence of the King of the Baggers series, and will debut today on the Harley-Davidson YouTube Channel and other social channels.

An exciting special round was recently added to the 2024 Mission King Of The Baggers Championship by appearing during the third round of the FIM MotoGP World Championship at Circuit of The Americas in Austin, Texas, April 12-13. This two-race appearance during the Red Bull Grand Prix of The Americas weekend will mark the first time an international audience will see the thundering King Of The Baggers bikes in competition. In addition to the two points-paying races on Saturday, April 13, there will be a three-lap Mission Challenge on Friday afternoon with the six fastest qualifiers battling for a $5000 winner-take-all purse. This special round expands the 2024 Mission King Of The Baggers schedule to 18 total races.

Wyman and Rispoli will compete aboard race-prepared 2024 Harley-Davidson Road Glide® motorcycles powered by modified Screamin’ Eagle® Milwaukee-Eight® 131 Performance Crate Engines. These motorcycles are based on the all-new 2024 Road Glide model, including the sleek new next-generation sharknose fairing design. Many of the race motorcycle body panels are formed with the same lightweight forged carbon fiber material featured on the 2024 CVO™ Road Glide® ST model. The team bikes also feature upgraded suspension components, including Screamin’ Eagle/Öhlins Remote Reservoir Rear Shocks, and competition Screamin’ Eagle exhaust, along with upgraded Brembo® Racing braking systems, Marchesini® wheels, and premium Harley-Davidson racing components produced by Protolabs®. The team motorcycles will appear in all-new livery featuring the classic Legendary Racing Orange color long associated with Harley-Davidson Factory Team racing bikes.

Wyman returns for a fourth season with the Harley-Davidson Factory Race Team. He won seven races during the 2023 King of the Baggers season and finished third in the season championship. Wyman is the most winning racer in MotoAmerica King of the Baggers history, with 12 total race wins in the 24 events since the start of the series in the 2021 season, plus the 2021 season championship to his credit. Wyman won the Daytona 200 in 2019.

Rispoli joins the team for the 2024 season after placing second in King of the Baggers series points in 2023 riding for the Vance & Hines Harley-Davidson team. In 2023, Rispoli won two races, and scored five second place finishes and three third place finishes. Rispoli began racing Harley-Davidson motorcycles as a teenager and earned the nickname “Hogspoli” after winning the 2020 American Flat Track Production Twins championship aboard a Latus Motors Racing Harley-Davidson XG750R. He also won back-to-back AMA Pro Racing Supersport championships in 2011-2012.

For the 2024 season, the Harley-Davidson® Factory Race Team is sponsored by Mission® Foods, Rockford Fosgate®, Brembo®, Öhlins®, Protolabs®, SYN3® lubricants, and Screamin’ Eagle® Performance Parts and Accessories.

The MotoAmerica King Of The Baggers series offers exciting competition between American V-Twin touring motorcycles prepared for competition and equipped with a fairing/windscreen and saddlebags. The 2024 series has expanded to 18 races over nine double-header weekends held in conjunction with the MotoAmerica Superbike Series. The series opens on the high banks of Daytona International Speedway in Daytona Beach, Florida, March 7-9. To experience all the King Of The Baggers action in 2024, check out the Harley-Davidson Factory Race Fan Ticket Packages.

2024 MotoAmerica Mission King Of The Baggers Season Schedule

(Two races each weekend)

March 7-9: Daytona International Raceway – Daytona Beach, Fla.

April 12-13: Circuit of The Americas – Austin, Texas (Red Bull Grand Prix of The Americas)

April 19-21: Michelin Raceway Road Atlanta – Braselton, Ga.

May 31-June 2: Road America – Elkhart Lake, Wis.

June 14-16: Brainerd International Raceway – Brainerd, Minn.

July 12-14: WeatherTech Raceway Laguna Seca – Monterey, Calif.

August 16-18: Mid-Ohio Sports Car Course – Lexington, Ohio

September 13-15: Circuit of the Americas – Austin, Texas

September 27-29: New Jersey Motorsports Park – Millville, N.J.

* * * *

FINAL DAY 30% PRES DAY SALE – ENDS TONIGHT

By Wayfarer |

President’s Day Weekend Sale. 30% Off Sitewide.

Starts today through 19-February 12 PM

CODE: PRES30NMC

www.nashmotorcycle.com

* * * *

House Motorcycle Caucus Leadership

By Wayfarer |

New Leadership For House Motorcycle Caucus

This week, the House Motorcycle Caucus announced changes to its leadership team. Congressman Michael Burgess of Texas, who will retire at the end of the year, has stepped down as co-chair of the caucus. Congressman Burgess helped found the caucus in 2009 and has been a tireless champion for bikers. He was the 2018 MRF Legislative Champion of the Year and we wish him well on his retirement!

The current co-chair, Congressman Tim Walberg of Michigan, revealed that Congressman Troy Balderson of Ohio and Congressman Donald Norcross of New Jersey will join him as the new co-chairs. Mr. Balderson and Mr. Norcross are longtime members of the House Motorcycle Caucus and strong supporters of biker priorities. The House Motorcycle Caucus has always been a bipartisan group, so we are pleased to see Representative Norcross, a Democrat, join two Republicans as a co-chair.

Additionally, the caucus named Freshman Congressman Derrick Van Orden of Wisconsin as vice chair. Mr. Van Orden is an avid motorcyclist who made a point to ride his motorcycle to the Capitol for his first day in office!

Thank you to all those who will lead and are members of the House Motorcycle Caucus. Remember, this organization and its sister group, the Senate Motorcycle Caucus, exist to educate, legislate and publicize the priorities of bikers on Capitol Hill.

Below is a current list of House Motorcycle Caucus members as of Thursday, February 15th, 2024.

Don Bacon (R-NE)

Troy Balderson (R-OH)

Jim Banks (R-IN)

Mike Bost (R-IL)

Angie Craig (D-MN)

Rick Crawford (R-AR)

John Curtis (R-UT)

Tom Emmer (R-MN)

Paul Gosar (R-AZ)

Glenn Grothman (R-WI)

Andy Harris (R-MD)

Dusty Johnson (R-SD)

Anne Kuster (D-NH)

Doug Lamborn (R-CO)

Tracy Mann (R-KS)

Mariannette Miller-Meeks (R-IA)

Donald Norcross (D-NJ)

Scott Perry (R-PA)

Bill Posey (R-FL)

Adam Smith (D-WA)

Pete Stauber (R-MN)

Bryan Steil (R-WI)

Chris Stewart (R-UT)

Glenn “GT” Thompson (R-PA)

Dina Titus (D-NV)

Derrick Van Orden (R-WI)

Michael Waltz (R-FL)

Joe Wilson (R-SC)

Ride With The Leaders ™ by joining the MRF at https://mrf.org/ or call (202) 546-0983

* * * *

SUBSCRIBE TO SUPPORT Bikernet.com – IT’S A FREE WEEKLY NEWSLETTER GODDAMMIT

Click here for newsletter options

VLXAFL5 Part 7 Final Assembly Begins

By Bandit |

It’s been awhile, but I haven’t dawdled. I’ve been working hard on various projects. That guy in Deadwood, who was once 45 John bought a 1960 Panhead roller/basket case and I’ve been helping with the reconstruction. I rebuilt or built and trans from a case and a sketchy box of parts. With Fab Kevin we built a front disc brake. John rebuilt the rear star hub and I helped with fitment and the rear brake.

I now have my son’s ’58 Chevy Belair and drove it to Spearfish the other day to the third mechanic. I have a good feeling about this one. He has a slick operation and was recommended to me by the TNT crew. It looks like the Carb may need to be replaced and or overhauled. I walked through the snow carefully into a large Antique barn and found a Rochester GM carb, amazing. I may see major progress in the future.

I sent the seat pan several months ago to the famous leather tooling expert Howard Knight. Howard is a master and the seat arrived just as the paint was completed. But I had a few more leather straps I needed make and one day, while cruising through Sturgis with the bros, we stumbled into Sturgis Leather. We met the longtime owner, fabricator, patch sewing maniac, seamstress, leather shirt maker, and metal artists extraordinaire Ron Hall. He’s been around a minute, part owner of a couple of bars and a bike riding fool.

I took him my strap projects for the oil tank and battery and he performed his leather magic on the spot, making suggestions and hand fabricating each piece. Bada bing, I had a completed battery strap.

I’m concerned about the battery. It’s not quite 200 cranking amps, and I’m not sure it’s enough to turn over a new, tight, 93-inch S&S Knucklehead engine. I’m thinking about a back-up Shorai or Anti-gravity lithium battery. Lithium batteries are dangerous. If your lithium battery gets wet and or catches fire you’re fucked and so is your garage, be careful.

My plan would be to keep the battery stored away from my home. We’ll see about that down the road.

I received my frame back from Tim at flat earth, but I wanted some additional pinstriping. As you can see above with Atomic Bob’s concept drawing, we initially considered a cream tank and fender with orange graphics, but somewhere in the mix I shifted. Let me know what you think.

Tim from Flat Earth has a process for giving the pinstriping a patina effect, as if it was pinstriped a long time ago. With TNT Paint, Tim and Nikki we discussed making the cream flat and the orange glossy. That worked for awhile, then we decided to flat everything, which had a major quirk.

Here’s a bunch of shots from their stellar shop.

“Don’t touch the flat clear,” Tim said. “It will go shiny. Don’t get anything on the paint, it will turn glossy.”

I sorta freaked. It’s a motorcycle frame and everything is open. I’m touching shit constantly and I’m not going to wear plastic gloves throughout the process. I tried, but then the gloves get greasy…

I cleaned and prepped my shop for the final assembly, painted my lift and the top of a couple of rusting benches with Valspar rust preventive paint. Travis at A&J Welding supply recommended it, but he said they don’t make it anymore. This stuff is the shit. It’s tough, thick and glossy. It was even fun to apply. I mixed white with black to get the gray I wanted.

As soon as the bike paint arrived completed, I anxiously greased my Timken neck bearings and installed the springer onto the lift and the frame onto the neck stem.

With the frame on the front end but still bare sitting on a pad I wanted to install the engine. John came over to guide the left side as I lifted the heavy engine off the engine stand. Before it could go into the frame, I needed to sand the paint off the motormounts.

Irish Rich modified this frame and he helped me modify the XA springer front end I got from Matt at Carl’s, with fork stops built into the bearing cups.

We slid in the engine after I stumbled. I used the rear axle and a flat lift jack to jack up the bike, so I could block it, remove the jack and start to install the 5-speed trans in a 4-speed S&S case. The trans didn’t want to go so I filed and ground all the paint out of the 4-speed slots and the slot I made and welded for the 5th stud on the right. I even had to grind the rear tab on the trans case more for additional clearance.

I couldn’t run an old school 4-speed trans for a couple of reasons. It’s an alternator S&S engine and I wanted it to be electric start.

I faced the toughest aspect of this build at this moment, the driveline alignment. If you followed this build, we’ve made several adjustments because of the alternator engine and VL frame configuration. Fortunately, I ran a very narrow rear Black Bike wheel and tire. The sprotor rear brake was also an issue.

With the engine bolted in place, and the transmission setting in the frame with maybe ¾ inch of adjustment, I needed to grapple with the front, Tech Cycle, single-row chain. The chain fit with the transmission moved as forward as possible. I punched the master link in place after adding the O-rings and additional white grease. Paul Cox coached me on the rivet-styled O-ring chain.

I was careful not to crush the O-rings anymore than any of the other plates had. Then I looked for a punch to do the rivet job. I didn’t beat it to death, but just a couple of solid smacks at a time with a heavy ballpeen hammer. The punch can’t be too sharp or I wouldn’t splay the head but just drive against the center.

Paul Cox said he used a sharp flat punch to make cuts into the rivets across it at 90 degrees to give the head four slices. Then he punched the head and could see how the rivet split and splayed. Interesting suggestion.

At first, I was very concerned about setting the masterlink. What if I had to remove it to remove the chain. As it turned out I could remove the whole drive line by removing the nut on the engine sprocket, the left-handed nut on the transmission and pulling the entire system free. I had to do this a few times, machine a washer perfect alignment, etc. I will need to remove it once more to install a Paughco tin primary piece as a chain guard.

Then I shifted to the rear wheel. I’ve installed and re-installed this bastard 20-some times. Everything changed, but ultimately for the better.

Everything was a struggle with the Sprotor brake system, so I shifted to the same thinking as the front brake on John’s Panhead. I bored out the hefty brake bracket to 1 1/8 inch. Amazing, I had a drill bit that came super close, then some grinding and sanding finished the job. Now spacing became a more direct operation and the caliper could adjust itself to the rotor for more efficient operation, I hope.

On the other side I found one spacer that worked but I didn’t like the outside diameter to the frame. I went with a shorter spacer and a 1/8 thick washer on the frame side. Everything seemed happy until I tried to mount the sissybar.

Keep in mind, everything was fine in mock-up, but during final assembly shit shifted. Now the rotor mounting bolts hit the machined carriage bolt even after I machined the head down. I was forced to take the wheel off again to install this machined carriage bolt. The hardware store didn’t have the 1 ¾ 7/16 coarse bolt I wanted. I ended up with a 3-inch bolts. I had to machine the carriage aspect off, cut the bolts to size and die-cut additional threads.

Even with all these efforts, the 12-point rotor bolts still hit the head of the sissybar mounting bold. I considered my alternatives and thought about replacing the rotor bolts with domed Allens. I thought for sure the bolts were 3/8 coarse bolts and dug into my fastener bins. No problem. I had what I needed and exchanged them with the chromed 12-points. Nice, lots of clearance.

Just as I was about to shut the shop down for the whiskey night, I picked up one of the 12-pointers and discovered it was a 7/16 coarse bolt. Un-fucking real. I immediately loosened the 3/8 bolts and reached out to McMaster Carr for more bolts—WTF. The wheel is coming off again. Then it came off to mount the fender twice.

Then I tried to install a rear chain. It was fine, but two short and my half-link wouldn’t fit, why. I ordered another standard chain a D.I.D job. Nothing is standard anymore. You can buy a 530 chain for as low as 37 bucks, all the way to a $150 for a chromed O-ring chain. Beware, they make standard chains, heavy-duty chains, O-ring chains, heavy-duty O-ring chains. They keep getting wider.

I’m going to compare the chain I have with the new one when it arrives. As you know, I have a serious issue with the width of the chain and my transmission case because the sprocket is reversed.

Next, I moved the wheel back to the center of the travel because I couldn’t get the Tech Cycle starter in place. I did, and it slipped into place. Remember we went through several changes to the clutch housing, sprocket placement, ring gear location and the engine sprocket. We moved the engine sprocket out another ¼-inch and we moved the clutch sprocket in about a ½-inch. They were close, but it messed with the pinion shaft housing on the starter.

I thought about using my Smithy to machine a notch in it. I would have need to create a mounting plate to clamp the cone into the milling machine. I chose the old school way by using my new grinding wheels to do the job, then the Scotchbrite wheel to smooth it and ultimately my Eastman buffing wheel to polish the piece. I did this several times until I had about 1/6th of an inch clearance above the chain. I’m going to keep a close eye on this during the warm-up and break-in stage.

I started to install my controls. I have them a light coat of Rust-o-leum satin black paint, making sure some rust was still exposed. I dipped and painted the handles with flex seal for a rubber-like grip.

Today, master cylinder, pipes, petcock, oil tank, oil lines, sparkplug wires and gas lines. Hang on. Hopefully, the toughest installation elements are over.

Ride Free Forever,

Bandit

My grandson is building a classic Panhead and asked me about gas tanks. Here’s what he said, “I wanted to be period-correct for the ‘60s outlaw look.” Sounded like Dominic talking, his mom’s boyfriend who builds classic chops. He’s a celebrated builder at Born Free every year.

It’s a kick. There are builders out there like Micah McCloskey, Paul Wheeler and Dominic who are religious and specific about how they build choppers. They are precise and follow the classic code.

It’s sorta funny. The whole notion of outlaws and choppers thumbs their middle fingers at any rules. Build whatever you want and fuck anyone who doesn’t like it. There’s the code of the west in a tumbler of Jack Daniels on the edge of a bar fight over nothing.

Photos by Weed

SOURCES:

Atomic Dice

Clauser’s Machine Shop

Spearfish, SD

Dakota V-Twin

Spearfish, SD

www.dakotavtwin.com

JIMS Machine

McMaster Carr

www.mcmastercarr.com

Paughco

Shamrocks Customs

Sturgis, SD

S&S

TechCycle

www.techcycle.com

Terry Components

Check on J&P Cycles

Nash Motorcycles

Colony

www.colonymachine.com

Black Bike Wheels

www.blackbikewheels.com

Custom Chrome

www.customchrome.com

Barnett’s clutch and cable

Dennis Kirk

Flat Earth Paint

Spearfish, SD

605-645-7192

TNT Collision and Glass

Tim and Nikki

605-641-8602

Sturgis Leather

Sturgis, SD

Carl’s Motorcycles

There’s Hope Bikernet Weekly News for February 15th, 2024

By Wayfarer |

Hey,

I often say, “Life is nuts and then you die.” But there’s hope, at least on one front this week.

There’s Hope And We Can Prove It! But I will keep it short.

In the meantime, get involved with your local motorcycle rights organization, so we can ride free next year.

The Bikernet Weekly News is sponsored in part by companies who also dig Freedom including: Cycle Source Magazine, the MRF, Iron Trader News, ChopperTown, BorntoRide.com and the Sturgis Motorcycle Museum.

Click here to read this week’s edition of the Thursday News only on Bikernet.com

* * * *

SUBSCRIBE TO SUPPORT–IT’S A FREE WEEKLY NEWSLETTER GODDAMMIT

Click here for newsletter options

Hero MotoCorp finally gets a podium finish at Dakar Rally

By Wayfarer |

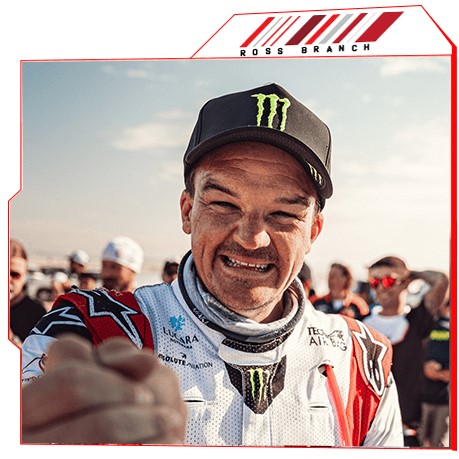

Hero MotoSports Team Rally, the motorsport team of the world’s largest manufacturer of motorcycles and scooters – Hero MotoCorp, has created history becoming the first ever Indian manufacturer team to finish on the podium of the legendary Dakar Rally.

Hero MotoSports Team Rally was formed in 2016 and it participated in its first Dakar Rally in 2017. Over the years, the team has achieved multiple podiums, wins and stage wins at top rally-raids across the world.

In its fifth year at Saudi Arabia, the 2024 edition of Dakar Rally was undoubtedly the toughest so far – longer stages, extreme terrains, and confusing navigation right from the start. Two new formats of racing were also introduced by the organizers to add more spice – a marathon stage early on in the race, and a 48H chrono stage during which the competitors were split across several bivouacs – away from their teams, and surviving on bare minimum essentials. As many as one-third of the competitors who started the race retired from the rally across the 14 days of grind.

To get to a Dakar podium is no small feat – a thousand things need to be right, and yet, each kilometer of these many thousands can destroy a result with a tiny mistake. 8,000 kilometers at the world’s toughest rally conquered with a top-2 result – Hero has made it clear they’re here to stay.

Ross Branch finished the Rally at the second place for the Hero Factory Team. His consistent performance over the 12 stages saw him at the first and second spots in the overall rankings throughout the Rally.