Road King 4/18/03

By Robin Technologies |

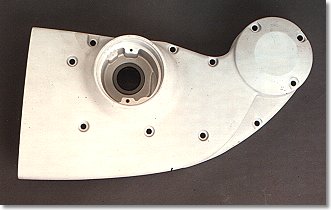

The King stripped for powder coating.

The plan was to strip the bike of all the brackets, tabs and accessories we could get our hands on and have them black powder coated by Custom Powder Coating in Dallas a Bikernet Sponsor.

We ordered additional accessories to enhance the clean black effect. First we ordered the Harley-Davidson black mag wheels and floating rotors with black centers. We pondered the front fender and trying to black out all the trim. During research we discovered, in the Winter P&A catalog, brackets to allow a Fatboy fender to be bolted in the King front end. The Fatboy fender is a cleaner unit, but it still has rivets and ribs. We opted for a solid black Street Stalker fender that’s clean as a whistle and light as a feather.

We also decided to switch the rear turnsignals out for the new Screamin’ Eagle teardrops and the narrower light bar. When they arrived we had to tear the lights down. We cut the two plug wires in a staggered fashion. The light bulb was then removed and we used a coat hanger tool to hook the plastic base and pull it out of the shell. Lastly we ordered the Harley-Davidson fender, license plate mount.

The first thing we did was to clear off our bench and tape down a couple of large sheets of paper. We organized every nut and bolt, screw and spring.

I ordered the billet seat tab from the catalog in the Multi-fit area. When I ordered a slim seat it didn’t come with a tab so I had to move the tab each time I switched seats. I powder coated both for more simple assembly in the future.

Nuttboy and I started the process removing the bags. I began the process of removing all the bag brackets and roll bars. Each time we removed a fastener we set it on the sheet of paper and wrote a description.

We had to pop the plastic side panel loose and take the seat off to get at the roll bar fasteners.

This shows one of the bag bracket fasteners that are inserted into the bag rails. I thought about pulling them for fear that the heat from the powder coating process would weaken the spring tension. We tested the theory by leaving some in place. We didn’t have a problem, either way.

On the left side I had to remove the passenger footboard to take the derby cover off. With each note on the sheet of paper we listed the number of fasteners for each application. The more information the better. I had to remove the seat and the King side panels to take the bag roll bars off. Many of these items were held on with Torx bolts. It’s a good notion to buy a set.

This footboard had to go to reach the derby fastener.

I started to remove the shift levers and discovered that I had to remove the footboard to reach the inspection cover Torx fasteners. I wasn’t sure if the footboards would have black in their future. At first I reviewed the area of the black board that would show, just the rim. Then we turned the board over and studied the way the rubber suspended pads were installed. We discovered that the pads are removed easily with a punch to the edges of the bottom protruding rubber lips. The boards went into the box for powder.

This was a simple process to tapping the edges of the rubber with a large tap and rubber hammer. We tried driving them out with the tap first, through the center. That didn’t work.

The mechanic’s law calls for one screw or fastener to seize every time. We had to drill out one of the inspection cover screws.

I tried to take off the kickstand the old fashioned way by removing the tooth then pivoting the arm forward. The spring wouldn’t come loose. I had to remove all the fasteners.

Metric fasteners haunted me from time to time, including the red Loctite touched horn fasteners which were #10 metric sockets. The Showa front end was covered with metric 12 point fasteners. It forced us to hit a commercial tool shop for 12-point metric sockets.

As the last of the fender rail parts came off we marked the loop that carried the license plate. We planned to replace the license plate holder with a fender-mounted job that attached below the taillight. We cut off the existing license plate loop, then I brazed washers and nuts so we could screw small orange reflectors in place.

We marked the old license plate rail with a felt pen so the cut would fall just under the fender rail cover.

We didn’t use these reflectors. We were looking for Harley orange reflectors with steel backs.

After a swapmeet run we had the right stuff for the job.

Sin Wu wandered into the garage just as I turned off the torch. She shuts down productive activity wherever she goes. She had a couple of alloy knitting needles that she offered us. I discovered in short order that the long alloy knitting needle worked perfectly for removing the hard-to-reach cotter key behind the brake pedal.

I had the toughest time retracting the clevis pin from of the pedal that hinged on the master cylinder piston. Finally it was removed with a punch from under the frame. The brake pedal caused me so much pain it didn’t make it into the powdercoating box. We painted it with a rattle can after prepping.

Continued On Page 2

The Amazing Shrunken FXR Project Part 2

By Robin Technologies |

Like the enigmatic fortunes you find inside thosefolded Chinese cookies, our visit with Dr. John–the”frame doctor,” was a mix of New Age mysticism andpractical guidance. The week before, Bandit and Ibrought the rolling Pro-Street frame to the gooddoctor. We gave the him our best ideas of what wethought the bike should become. Basically, we wantedthe bike to fit my body proportions, to shrink theframe around the engine and to still have elements ofa street chopper.

Bandit and I had been trying to create a bike that hada real “signature” identity, yet we weren’t sure whatthat would mean. We tried to convey our concepts withawkward babbling.

Stroking his long, gray beard with a knowing gravity,the doctor calmly listened to our ravings. Eventuallyhe gave us a broad grin through the tangle of beardand said, “Don’t worry, boys, I understand exactlywhat you need.”

We had left the bike with vague misgivings.”Do you think he really has a clue what we want?” Iasked Bandit.

“I dunno,” Bandit said, staring off into the acrid,smog-laden sky.”The guy’s kind of strange, but everyone I’ve talkedto says the guy’s a wizard,” Bandit musedmysteriously.

When we pulled up to Dr. John’s shop, there was ourcreation leaning up against the wall. Not averse tostreet-corner poetry, I intoned, “What a bitchin’fuckin’-lookin’ bike.”

“Man, that bike is really unique,” Bandit exclaimed ina more civilized tone.

As we oohed and ahhed about the bike, Dr. John camearound the corner, grinning. I jumped onto theseat-less bike and grinned. It fit perfectly, betterthan an O.J. leather glove.

“I really think you’ve got something good goingthere,” the doctor spoke with unconcealedappreciation. “I wasn’t sure it was going to workuntil I got into it. The bike began to speak to me. Ithink it’s got the right karma,” the doctor spoke withmysterious gravity.

All this mystery was not without reason. Dr. Johnstarted this trek to ultimate frame adjustment workingat Goodyear Tires. A fortuitous opportunity, sponsoredby Goodyear, for advanced training at L.A. Trade Techgave him the chance to try motorcycle repair.Recognizing that he was more interested in bikes thantires, he began a course in bike repair withinstructor Pat Owens.

Dr. John soon connected up with a bike shop calledMotorcycle Menders. Right away, he could tell that hehad a better-than-average sense of what was needed tofix most frames. Eventually, he opened his first shopin Covina in 1983. In 1990, he moved to his presentlocation in Anaheim.

Dr. John’s expertise is extended to both traditionalstreet choppers and to the more exotic road racebikes, where competitive tolerances and alignmentshave seconds off of lap times. The challenges to hisexpertise in frame adjustment include the extremes ofcreating a bike for a 6’9″ rider and a Harley with a25″ over stock front end. For his own use, he isbuilding a karma-tingling three-wheeler with a VWengine.

In his shop, amongst a tangle of tweaked Ninjacarcasses, “destruction derby” ATV frames, twistedchopper forks and even a mangled Vespa body, Dr. Johnholds court. Side-tracking his stories about gettinginto the frame adjustment business, he mixes conceptsof metal stresses with ideas of mental stresses,Eastern philosophy, acupuncture points, shakras andauras, martial arts movements, elements of a good dietand muscle alignment of the spine.

The conversation stumbles easily into his personalexperiences. After an injury of his own, he explored avariety of methods of pain control, eventually meetingan American Indian psychic whose exotic beautyhypnotized him as much as her cosmic consciousness.Here, a glint comes to his eyes and a wry smile bringsone corner of his mouth up. “A rare beauty,” hemuses. “An aura just like Cleopatra of ancient Egypt.”

Bandit nodded in agreement repeatedly, like thoseDodger dolls that bobble in the back windows of cars,to the good doctor’s banter. Bandit slurped his greentea while listening to enchanting tales spun by theDoctor. While I shoveled in heaps of steaming andspicy-hot Kung Pao chicken, my eyes teared up and mynose started running.

“The magnetic flow is a flux of energy in the bodyof…” The steaming pots of green tea and plates ofexotic Chinese food sent wisps and tendrils dancing inthe air above our table like a chorus of swaying,sensual nymphets.

“The assorted colors of shakra balance…” Thisadventure had the aura of Zeke the Splooty about it.We were on a cosmic motorcycle Magical Mystery tour.

An hour or so later, Bandit and I were back on the 91Freeway with the bike strapped to the bed of hispickup, staring ahead kind of dumbly. “What a trip,Dr. John is,” I said.

“Yeah, but I think he did a great job on the frame,”Bandit said.

“Yeah, cosmic man,” my head was stuck in the ’60s.”What do we do now?” I asked.

“Let’s check out some trippy paint for the bike,”Bandit smiled. “Let’s drive down to Stanton and see ifWes at Venom can come up with something exotic enoughfor this mystery machine.”

“Go for it,” I laughed.

It’s days like these that make bike building seem likethe right thing to do. Bandit slapped in a tape of’60s funk and we were sailing down the road like acouple of latter-day Kerouac and Keseys.

“Hand me a bigger hammer, goddamn it,” Bandit hollered across the garage. We were slamming together as much steel as we could to get this Frankenstein of a bike together in time to show it to the crowds at the Queen Mary Motorcycle Show this weekend.So far this week we’ve managed to cut 1.5 inches off the swing arm. This brings the wheel into the back end of the bike at the point of the pivot. We are designing the bike with brevity in mind. We are hoping that the finished impression will be a bike shrunken around the RevTech 88-inch motor and Rev Tech 6-speed. Oh, we’ll have devilish accents here and there, but the overall concept is lean and mean.

To that end, we are cutting off any unnecessary tabs and struts. Of course, everything changes as soon as a UPS box arrives. Joker Machine parts arrive every couple of days. The foot controls arrived. The new front Avon tire should be here Monday or Tuesday. It arrived, we had it mounted pronto and the fender was looking good. I hauled it to Urs who is a master body man and he widened it to fit perfectly. Having the right tools makes a big damn difference.

A new front tire was called for because the sexy front fender from Cyril Huze was too narrow, since he builds bikes for 19 and 21-inch from wheels and we’re running an 18 (our fault).

After banging the hell out of the fender to try to squeeze out a fraction of an inch clearance, we decided on a smaller sized tire. We ordered an 18/ 100-90. We hope this will allow us at least 3/8-inch all around.

The new Cyril designed stretched tank arrived with the fenders. We cut out part of the bottom of the tank at the back where the front of the seat is, since every goddamn thing we do is backwards. Every builder in the country stretches bikes, we shrink ’em, so the tank won’t fit without mods. This move helped bring the tank down closer to the engine and since the FXR is short, well you get the picture. The tank tabs are in place and welded.

We decided to use an old rear fender off one of Bandit’s past bikes–a Fatboy. We turned it around backwards, the front end will be bolted to the center of the swing arm. Our next problem was how we were going to hold up the stern. After a lot of head scratching, cussing and phone calls we met with master fabricator James Famighetti who suggested that we create our own struts that will be bolted on the inside of the lower rear shock absorber bolt, then welded to the outside of the fender in such a way as to add to the over all look and strength of the fender and conceal the stock aspects. Mounting fenders to swingarms is treacherous. It will vibrate like a dog attacked by killer bees, so it better be strong and still able to remove for touchup.

No problem, you say? Ah, ha, not so easy kimosabe! We are pretty sure the strut will have enough clearance for the Rev-Tech brakes on the right side of the rear tire. When you come around to the left side, you’ve got the pully to contend with. So on this strut we added a 2″ dog leg to clear the pulley. I made up the patterns on cardboard and the Fam-Art brothers cut and bent the pieces. Then it was time to fit. We’re getting there.

The BDL pulley from CCI is smaller than the one we used for the mock up. So with our fingers crossed, when all these parts come together this week it will be amazing if they all fit. They did, well, perhaps not perfectly, but we’re getting close.They did, well, perhaps not perfectly, but we’re getting close. If not, “Bandit, get me a bigger hammer, goddamn it!”

Here’s the score. The fender needs tabs and it’s ready. The rear fender needs rivet removal and the massive tabs tack welded. The shock tabs have been cut since the Progressive Suspension shocks from Custom Chrome need to be set wider away from the fender tabs. Let’s see if we can make it to the show. We’re still waiting on Huze oil tank mounting tabs.

The saga of the Amazing Shrunken FXR continues. This project is notonethat is merely slapping together after-market products to build a facsimileof a customized Harley-Davidson.From the start, Bandit and I sought to create a unique ‘signature’ bike.Even though we have used a lot of after-market products, most have beenmodified to fit our design plan. The products we use, from the FXRPro-Street frame to the Rev-Tech engine to the Joker Machine qualitycomponents, to Cyril Huze, Avon and BDLare some of the finest products available.

Because some of the fundamental elements of design were modified, we havebeen constantly fabricating new brackets, tabs, mounts, and studs. Eachmodification created new issues relating to the fit and function of thedrivetrain. It seems as if we’ve bolted and unbolted the elements of this bike ahundred times.For example, the frame was modified by Dr. John to fit the Rev-Tech engineinto our overall design concept. The top motor mount was bent to fit thenewspacing. We used this motor mount point to position the Cyril Huze teardropgas tank. When we positioned the tank we related it to the handle barclearance at maximum turn position. Rubber mount brackets were welded inplace. The tank was cut at the underside back end to fit low on the frame.It looked hot. Next I cut the La Pere seat pan to hug the pointed rear ofthe gas tank and strengthened the seat back. There is a continuousdouble-‘swoop’from the handle bars to the back of the rear fender. The seat pan lookedhot.

Then we tried to put the engine in. It didn’t look fit. The engine wasmere fractions of an inch from fitting. Even if we could have hammered itinplace the subsequent tight tolerances would surely create problems as thebike rattled and roared down the road.

At this point, we cut the original tank brackets and repositioned themodified tank a little higher on the top frame tubing. The tank looked hot,the engine fit, but now the handle bar swing is a fraction of an inch tooclose to the tank. This means we will probably have to have custom handlebars.

It still looks good and we’re still optimistic. Even as wedroppedthe tank down on the new rubber mount brackets and began putting in the5/16″bolts, we found that the right rear bolt was too long to fit. So we got abolt with a thinner head and with my small fingers, I got the bolt in andstarted. We were still looking hot.

We decided to see if the belt fit since Bandit had cut andrewelded the swingarm 1.5 inches shorter for that Amazing Shrunkenlook. Bandit said no, the belt wouldn’t fit. It wasn’t suppose to. Isaid it looked close. As welooked at the bike we realized we’d had to remove the engine, drop thetransmission, which meant we’d have to support the swing arm. It alwaysseems harder than hell to make something easy. So with a couple of scissorsjacks, hunks of wood, and a crow bar, we were able to loosen the rubbermounton the left side of the pivot point of the swing arm. Then we gingerlyslipped the belt in, put the rubber mount back and bolted everything backtogether. Damn! It fit perfect and we were looking hot.

Wait a minute. The right side of the belt was almost touching the edgeofthe back fender. Quick surgery with a saws-all cut a chunk out of thefender. Fender fits, belt don’t rub, bike still looks hot.

As we cram more operational parts together, the room to move gets lessandless. Next we positioned the oil bag, which also brought up the issue ofthebattery accessibility. With bungee cords, a busted yard stick and some woodshims, we finally got the bag in what seemed a reasonable position. Fourrubber mounted brackets were fabricated then welded into place. It lookedHot. Everything was bolted in place. And everything looked Hot.

Ah, but not so fast kimosabe. We shaved the fins off the back ofthe oil bag for more clearance. With the two rubbermounts in place atthe rear of the oil bag under the seat pan we had enough clearancefor the battery, in the front for the engine and exhaust, under itfor the starter motor, but no clearance for the ever moving rearfender. It needed at least 1.5 inches of shock play since it’sattached to the swingarm. We had to peel the bag out of the frame andtake it to the Famighetti’s metal fab shop, Fam-Art, for theirexpertise. They came up with a plan to scoop out the back of the bagto the battery box without shortening the overall look of the bag.Then the fender will have the clearance to move with the swingarm andstill look hot.

Next, we neet to investigate whether the Joker controls canbe mounted mid frame. At the same time we will begin fabrication ofthe Amazing exhaust system. It’s gotta be lookin’ hot one way oranother.

–NuttBoy

To Continue……..

Back to Part 1……..

Back to Custom Chrome on Bikernet……..

Back to Joker Machine on Bikernet……..

The Amazing Shrunken FXR Part 5

By Robin Technologies |

You’ve been there. You handed the Makita cordless drill toyou’re drunken buddy, and he drilled a hole in your big screentelevision. You tried to wrap the extension cord around his neck andfinish him off. We came close to blows in the garage a couple ofmonths back. I spent days carefully welding chunks of Samson exhaustpipes together to form a one-of-a-kind exhaust system.

All the welds were performed with gas and hanger rod. Thepipes weren’t perfect, but they fit the bill. They were actuallyintended to be prototypes, to be duplicated by a paid professional.After the first pass was completed the pipes fit like a glove,although they were artistically rough around the edges. Nuttboy cameby on his Wednesday afternoon escape, and I handed him a highspeedgrinder and instructed him to round off the welds. I worked onanother project and paid no attention while sparks flew. When he wasfinished he tapped me on the shoulder and said humbly, “Not sure thisis what you had in mind.”

He had ground right through the pipes and left gapingholes alongside most of the welds. In addition, I discovered to myteeth-grinding dismay, that there were still large sections of thepipe ground so thin, that as soon as the torch tip came within 6inches of the surface the pipe melted away. I spent another whole dayfilling the gaps. Who knows what will happen when the struggling bikefires to life. We’ll have the only exhaust system on earth withbaffles throughout.

That’s not all. The grief continued. I hand made a mufflerusing a portion of a Samson baffle. We purchased a chromed, truckfender tip from San Pedro Muffler and went to work, but after hoursof screwing with the shiny metal we almost shitcanned the unit. Thefender tip was made out of a strange metal, almost pot metal, thatdidn’t seem to take to the gas welding and wouldn’t respond tobrazing. For every hole I filled, another crack lurked. I welded,then smoothed on a bench grinder only to find cracks and holes tofill again. The shorty muffler probably weighs 50 pounds due to thevast layers of welding rod. As it stands, this is a pure prototypeexhaust system. We should use it for testing then shitcan the rankpiece of shit and start over.

Click to order Catalog!

Frustrated, but pleased with the overall look we were readyfor final metal work. This bike is being built by inexperiencedhands, not professionals, in our backyard garage. Sure, I’ve builtsome bikes, but I wouldn’t consider myself a metal fabricator. I cameup with the initial design and we roughed out elements, but we neededa master metal worker to finish what we started. There are preciousfew, true metal craftsman, who I know. One is Billy Westbrook,another is Jesse James and recently, in the news, we displayed metalwork by Roger at Goldammer (Goldammer Cycle Works Ltd.,www.goldammercycle.com ,1-250-764-8002). High quality workmanship.

They’re out there but not on every corner. I stumbledonto another super-slag artist under my nose. James and LarryFamighetti are Hamsters and own a corrugated steel metal shop inHarbor City, California, called Fam-Art. You’d be tweaked to rumbledown Narbonne Street and stumble across this rusting corner buildingthat’s got to be the oldest swaying dump on the block. Theyspecialize in structural steel (you could never tell it from theircreaking tin shed) for homes and buildings. Large chunks of steel,massive shredders, presses and welders are scattered around the funkylocation that’s reminiscent of the first shack Harleys were built in.

Nuttboy and I darkened their doors a couple of times toask them to flame-cut a couple of chunks of steel for our fenderbrackets. The more I hung around the more quiet-James began to showme steel components he had fashioned for some of the local riders. Herebuilt and reformed Harley taillights to eliminate all the edges andgrooves, then welded them to fenders so that ultimately there were noseams. The more I gawked at the sculptured parts, that demonstratedhis ability, the more I knew we had discovered a man capable of BillyWestbrook fabrication qualities. We hauled the entire FXR to Jamesthe next week.

James relocated the straps in such a way to narrow the shockplacement keeping that shrunken look in mind.

This is a close-up of the right fender strap. It’s beencorrected, reformed and readied for final welds.

We cut and fitted the tank and made the mounts, butJames filled the underside, rear section for a perfect fit.

We jacked up the front of the tank and mounted it, butJames filled it and formed the front of the tank to match the customridge along the top. He even made paint work suggestions that I foundinteresting. “If you paint a ridge like this with a light color,”James said, “The ridge will disappear.”

We decided to paint the bike a light House of Kolors pearland create a dark teardrop panel on the top of the tank. He alsocreated and welded fork stops to the neck.

As we rolled out of the shop that day James still hadfinal welds to complete. He straightened out our seat pan, but neededto figure out a mounting arrangement. Finally we needed the CyrilHuze front fender brackets checked and welded into place.

We should have the Shrunken FXR back in our clutches inthe next couple of weeks. We need to finish our rear brake andshifting mechanisms with Giggie from Compu-Fire, fire it up for atest ride and tear it down for paint.

Oh, I need to untie Nuttboy. I need that extension cord.

The Shrunken FXR returned recently from Fam Art, in HarborCity, California (310-326-2141). They welded, shaved, mounted theseat, manufactured fork stops and saved our poor- construction asses.James Famighetti mounted our Cyril Huze front fender, welded andformed the tabs and informed us that the Avon Venom was too large forthe narrow glide front end. It was our turn to work on it.

Note that James mounted the seat pan so that the edges wouldnot touch the frame paint in the future.

Like any self-respecting bikers we hate to have a bike, oreven components out of our mistrusting mitts. We had another dilemmathat needed handling. The bike still didn’t have a kick stand, and weused two 2 by 4’s, to hold it upright, when not perched on the lift.There’s a trick to this maneuver. If I backed the Pro Street FXR outof the garage and wasn’t hauling the wood planks, I was screwed. Ifalone, I could stand there for hours waiting for someone to strollpast carrying two 2 by 4s–unlikely. After a couple of unsteadyoccurrences, the bike didn’t move without the wood chips on the seat.You can imaging the major pain in the ass this caused.

We ordered a weld-on, Sportster style, kick stand fromCCI, and it arrived complete, with all chromed hardware and thebracket to be welded on the frame. There was one problem indetermining the position. The front Avon was a 100/100 18-inch, andwe planned to replace it with a 90/90. We needed to have the finishedPerformance Machine wheel in place.

The Avon Road Runner tire arrived, and we had it installed at thelocal Yamaha dealer. James pointed out to us that our front tirespacing wasn’t perfect so I sliced a spacer to give us about a1/4-inch spacer on the right side of the wheel and about a 3/4 inchspacer on the left. The tire, almost centered, now had clearance, andthe wheel floated effortlessly under the modified Cyril Huze frontfender.

Now we were cleared to install the Hot Match weld-on kickstand.This is a tricky assembly process. First, you need to be absolutelysure you don’t plan to change the front wheel, to a 21, or extend thefront forks. If you do, the kickstand will need to be bent ormodified to fit. It’s not the end of the world, but it will destroythe chrome.

The other trick is determining the right position. Here’swhat my feeble brain told me, since the directions with the Hot Matchdidn’t cover positioning, except to recommend that you take yourtime–no shit. First I stood my Road King straight up and lifted theside stand until it was locked in place. Then I measured from thepoint that would touch the pavement to the ground. It varied fromaround 2.5 inches to 3 inches. I noted that the Hot Match lever wasnearly 3 inches shorter from the point of contact to the center ofthe pivot point. I took that into consideration. I also noted that Ihad lowered my King with shorter shocks, then added a larger Avontyre (a 150). Ground clearance was also a consideration.

Then we picked a placement area on the frame. Our designcalled for little or no forward controls. I kept the tab under theBDL belt drive system and hidden as much as possible, without beingso far back as to create a balance problem. If the weight is forwardof the kickstand, sometimes it can topple the bike. One otherconsideration. When the stand pops up you need to be able to reach itwith a toe, and it better not ride on the belt, or you’re toast. Makesure to check all that, before you burn any rod.

I sprayed the frame rail and the components with asilicone splatter preventative. It obstructs slag from sticking tocomponents. It also made the frame a slipper bitch. I tried settingthe stand end on a socket nearly 3 inches off the deck. Then Iconsidered the differing lengths of the stands and shifted to 2.5inches. Sin Wu was called, from the bedroom, to hold the stand firmlyin place. I marked it, with a grease pencil, then ground the edges ofthe bracket to be welded to the frame. Extra grinding took place toform a snug, metal to metal fit. In order to make all this work weneeded to partially assemble the kickstand without the ball andspring.

The easy-to-read directions called for disassembly, but we left ittogether and used it to hold the bracket in place for tacking. Beforetacking I backed the bike out of the clamp, holding it upright,positioned the bracket in the white grease pencil marks and leanedthe bike carefully until the stand rested on the flat surface. Itlooked cool, so we re-clamped the bike securely, held the stand inplace, protected the belt from hot slag and tacked the sucker withour Millermatic welder. Then we took the stand arm off the bracketand welded it some more. That would hold it securely until we torethe bike down for paint.

The Hot Match unit from Custom Chrome is a well madeprecision unit delivered show chromed. The instructions includedrecommendations to apply anti-seize to the spring and ball. Theyendorse using Red Loctite on the pivot pin threads. We didn’t becausethe bike would be torn down for paint in the near future. The armneeds to be placed firmly over the bracket and pushed into placebefore the pin will ease into the hole from the bottom. It doesn’thurt to have a spare set of hands and someone holding the bike.There’s also a pivot pin set screw to prevent losing that preciouspivot pin and kick stand arm, on a desert highway, in the middle ofArizona.

That’s it, except to mention that when we head to thepaint shop, we need to tape off the chrome bracket, so the painterwill paint over the welds but not the chrome tab.

As you can see this bike is damn close to the spray booth.I need to coerce Giggie, from Compu-fire, to ride his FXR out to theBikernet Headquarters with our mid-controls. Once the Joker Machinehandlebar controls are bolted to the modified bars, we’re ready for atrial run, then off to paint. Stay tuned.

–Bandit

Custom Chrome ® and Chrome Specialties ® have joinedforces to bring you the most comprehensive product offering in theHarley-Davidson ® aftermarket! At over 1,400 pages and over 25,000part numbers, our 2003 Catalog features everything from nuts & boltsto HR3 bike kits, and sets the NEW industry standard.

ONLY $9.95 + 6.95 Shipping**

–Bandit

Back to Part 4…

Road King 4/15/09

By Robin Technologies |

We decided to take a run at an electrical article, since about 90 percent of problems and breakdowns come from the electrical component. Besides, it’s riding season and we all need to check our electrical connections before we ride off into the sunset. This is especially true of bikes stored in moist or seaside climates. Besides, I’m riding the King to Laughlin and need to check it out. It’s been awhile. Here’s the lastest upgrade to the king: King Meets Zippers and D&D

This article will cover some basic electrical checks, since being forced to charge your battery indicates deficiencies in your charging, or wiring system–or you left the goddamn lights on.

This rambling will also cover all the aspects of the latest battery charger from Biker’s Choice, the Xtreme 12-Volt battery maintenance charger. If you find it necessary to charge your battery, take it out of the bike and place in on a wood or fabric surface, not steel or concrete (draws battery charge). Make sure the terminals are clean. A loose or corroded terminal will prevent the battery from accepting a charge. No shit, just that will leave you along side the road.

Corrosion, or bad grounds cause most electrical problems, especially in dense humidity climates. Check your grounds annually; clean the connectors and the ground surface.

Batteries are nasty dangerous bastards. Make sure to protect yourself around them. Don’t mess with a battery near flame, extreme heat or next to your custom painted Ferrari. If the bastard explodes, you could lose your eyesight and that $5,000 paint job. And that acid crap is super nasty. Don’t get it on anything. There is a cure. Mix some baking soda and water and have it standing by to clean anything with battery acid splashed on it. This is no jive. If you get battery acid on anything, it’s toast. Believe me. I have a number of holy shirts from acid meetings.

Wear eye protection and don’t fuckin’ smoke around batteries. Fortunately, for incased batteries, we don’t have to mess with acid as much anymore, but I’m still building choppers and using bullshit little batteries with acid requirements. Whatta mess. Make sure the area used for charging is clean and well ventilated. Okay, enough for the safety procedures. The Xtreme Charger comes with complete safety warnings.

For years I liked Battery Tenders, because they monitored the charging process and dropped the charge level automatically, when the battery was completely charges. If the charge level dropped, the automatically kick into gear again. This Xtreme charge handles those tasks and more to keep your battery strong and charged. Below is the full description of the Xtreme capabilities. The kits also come with a lead set you can bolt directly to the battery for easy access at anytime. Check this out, then we’ll give you some testing, trouble shooting electrical tips:

The Xtreme Charge is ideally suited for AGM and Maintenance-Free Batteries. The combination of PulseTech’s patented pulse technology and proprietary charging algorithm allows it to charge these high-performance batteries more fully while maintaining a safe charge profile for traditional batteries.

The Xtreme Charge Battery Maintenance charger comes in variety of colors, which may suite a particular need. If your looking for the best battery maintenance charger for use on any 12v battery rated from under 10Ah to over 150Ah, pick your color, and get one today.Includes fuse-protected quick-disconnect battery clamps and lugs, Important Safety Instructions and Quick-Start Guide. The Xtreme Charge is fuse-protected, spark-proof, and is UL and CE certified.

Comes with a Five-Year Warranty

Xtreme Charge Maintenance and Charging

The Xtreme Charge is a microprocessor controlled maintenance and bulk charger for any type of 12-V lead-acid battery. It features PulseTech’s intelligent circuitry, which imposes only the correct amount of charge rate as determined by the continual evaluation of the battery’s condition. By using only the appropriate amount of charge rate, the battery is maintained safely at its proper operating voltage indefinitely. Conversely, if the charger is connected to a discharged battery, its bulk charge capability (2.5A actual/5A effective) will re-charge the battery rapidly and safely so it can be put back into service quickly. Charge rates may be as minimal as 0.2A during typical float up to the full 2.5A for more deeply discharged batteries. This variable float charge ensures optimal charge rate is applied to the battery at all times.

PulseTech’s unique and patented PULSE technology increases the duty and life cycles of your battery by minimizing the size of the lead sulfate crystals. This allows a battery to accept as much charge as possible. PULSE technology helps ensure that your new batteries will stay in like-new condition while improving older batteries dramatically. Duty cycles are typically extended from three to five times for all types of lead-acid batteries!

PulseTech’s ReNew-It Pulse Technology

Twelve years ago, PulseTech applied its technology to a full line of innovative and unique products designed to make batteries stronger so they will work harder and last longer than ever before.

To get an idea of exactly how important PulseTech’s technology is to the performance of all your powersport toys, consider this: The main cause of vehicle failure is battery failure. The main cause of battery failure is sulfation buildup on the battery plates. And ReNew-IT Pulse Technology prevents sulfation buildup.

When it comes to a dead battery, chances are it is still good. You just can’t reach the energy due to sulfate buildup. That means you have to buy another battery even though the one you have may still be useable. Xtreme Charge helps prevent this problem.

How Renew-IT Pulse Technology Makes Batteries Stronger

PulseTech’s Xtreme Charge connects directly to the battery. The Xtreme Charge emits a pulsating DC current that removes the sulfate deposits from the plates and returns them to the battery acid as active electrolyte.

Here is how it works:

1. Lead-Acid batteries work by releasing energy through an interaction that occurs between the positive and negative lead plates and the lead sulfates in the electrolyte.

2, Sulfation buildup occurs as lead sulfates form on the battery plates during the normal charge/discharge cycles. During this process, some of the sulfates enlarge to the point where they won’t accept energy so they stay on the plate. Over time these sulfates can build up until efficiency is reduced and finally the battery dies.

3. ReNew-IT Pulse Technology works to prevent sulfation buildup by removing the sulfate deposits from the plates through a unique Ion Transfer process.

4. The lead sulfates then return to the battery acid as active electrolyte. When connected on a regular basis, our battery maintenance systems will also keep the sulfates from building up again.

Get True Battery Power

PulseTech’s technology works with all types of lead-acid batteries including sealed, gel cell & AGM. By keeping the plates “clean”, batteries charge faster and deeper so they work harder and last longer than you ever thought possible. They also have greater charge acceptance so your battery will recharge faster and release all of its stored energy. With more available energy so your vehicles last longer between recharges and your electronic accessories work better. You get the true power of your batteries.

Some of our patented products also prevent the normal loss of battery power on stored vehicles and equipment no matter how long they sit unused—even months at a time.

They even help protect the environment. Since batteries last longer, it reduces the danger of contamination caused by lead and sulfuric acid dumped from prematurely discarded batteries.

Xtreme Charge 5 Stages of Charging

1. Initialization: Xtreme Charge’s unique test feature evaluates the battery thoroughly during initial connection to determine the appropriate charge rate based on its size and condition. It tests the battery continually for as long as it its connected to the charger to maintain the optimal bulk or float charge rate. This test step incorporates a “Bad Battery” indication if it determines the battery is faulty and can not be charged.

2. Saturation: A proprietary computer-integrated technology measures both the voltage and current to determine the appropriate amount of charge the battery is able to accept at any given time. As the pulse and saturation charges improve the battery’s condition, the charge rate is increased safely to an optimal level. This proprietary algorithm protects the battery from the risk of damage due to overcharging.

3. Storage(Float)

4. Pulse(De-Sulfation)

Testing Tips

I reached into a couple of Harley manuals and to Pablo, our Bikernet Harley factory trained technician for additional info. If you suspect a problem with your charging, you’re experiencing sparking when you hit the starter, or the battery needs to be charges, here’s some tips.

First, check all your grounds and battery posts for connection and cleanliness. Then take a voltmeter and run it across the batter whiled the bike is idling. It should indicate 12 volts (see chart). Now run the throttle up to about 2,500-3,000 rpms. The indication should jump above 14.1 volts, indicating that the charging system is working.

Before you toss the regulator and replace it, you need to check the connections with the alternator. Make sure you haven’t lost a ground or run over a speed bump and ripped through a wire running along the bottom of your frame, which is against the code of the west. Don’t run wires under frame rails. Keep them up and out of harms way.

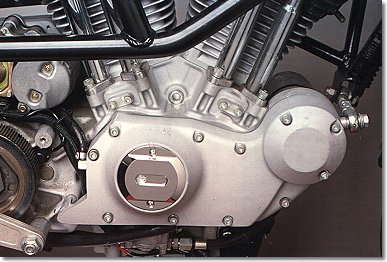

To check the alternator, here are a couple of tips. Pablo suggests that you take an old regulator plug, with the wires and create a testing lead. If you check the resistance to ground on each lead, they should be open. “But if you take the derby off your primary and run into that burnt electrical smell,” Pablo said, “the alternator is toast.” There’s also an AC test. Start the bike and run it up to 3000 rpms. Attach your alligator clips to your alternator leads and it should read over 40 volts or 16-20 volts per 1000 rpms.

“With the newer models, we have seen some issues with the bikes having batteries going dead after a couple of days,” Pablo said. “A milliamp draw test and total current draw test is the first things you check in the H-D flow charts. Corrosion on the system relay on some models can cause this.”

“The service manual, including the electrical diagnostic manual are a must on the new models. You basically have to be a Circuit Head to work on these things nowadays. The H-D Digital Tech we use at the dealership also helps with the serious hard to find electrical gremlins.”

“Fuck, I’m just a old Seabee resistant to change. Man invented technology to frustrate himself you know. Just look at what we have done to a motorcycle over the years. Seriously though, one can, with a cheap DVM (Digital Volt Meter) do allot of trouble shooting on the H-D charging system. Like checking the stator for AC volts output. A grounded stator, continuity checks, etc.”

One more addition from Pablo: DC Voltage output at the battery with the bike running is also a quick check. The system should be putting out over 14 volts but not more than 15 volts at 3000 RPM. Usually, you will see like 14.1 to 14.4 volts or so, that is if the regulator is good and shunting excess voltage to ground.

So, with the Xtreme Charger and a volt meter, you can check your battery, the charging system, the alternator and check for bad grounds and busted wires. That’s all you’re gonna get from the Bikernet tech staff today. Let’s go to the Cantina for a beer.

Sturgis 2001

By Robin Technologies |

Buells are the Harley-Davidson street fighter. They are inexpensive,sharp-handling machines that give the American rider something toshout about, something to fuck with and something to race.

This bike won’t compete with the 200 mph Japanese sportbikes, but it will handle like one, and brake like one. So we gothold of one and evaluated it for the Sturgis 2001 run. Since I come from a custom bike or chopper background, I wasn’t sure the Cyclone would do the job for me. If you ask a guy who rides a custom bike what style of bike he enjoysand why, the answer might be strange. I want something distinctiveand bad. I want it fast and cool. I need it to handle, but be achopper. Perhaps an oxymoron of conditions, yet there’s a mixture offactors that go into any ride and machine. Last year I rode astretched rigid with a 14-over front end. What a machine. For a rigid,it rode like a dream. For a 14-over front end, it handled well and Ipassed everyone I dared to pass, generally because I had the groundclearance to shove it close to the pavement and the raked tripletrees allowed me to turn the front end where I needed to go.

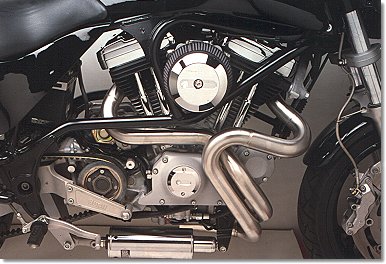

Each year the trek to the Badlands takes on a differentdemeanor, and this will be no different. After a week, I discovered a serious sense of enjoyment about straddling the M-2 Cyclone. It’s light, fast, a nimble handler that stops on a dime. I needed to learn to ride it like a race bike with my toes on the soft rubber pegs to enhance turning radius and ground clearance. There is also a notion that in the sportbike position, you’re forcing too much weight on your wrists. I discovered quickly that if I put my ass down,the weight on my wrists was not a problem. The force is substantial, however, when braking with a passenger on board. Ultimately, after riding two Buells, I decided that this motorcycle deserved a shot at aSturgis trek. It had class, felt sporty, even nasty, and I could makeit rumble. So I stood back and thought, “Can I make it even cooler?”It didn’t take long to discover that I could strip it down evenfurther than stock. I picked the Cyclone over the model with hard bags because of its bare bones feel. The crew here at Bikernet.com developed a five-pronged approach. One, we wanted toenhance the Harley-Davidson marriage with Buell and downplay thelittle-known name Buell for the time being. We also wanted to enhance the Sportstermotor and bring out the looks of the Harley-Davidson power plant, andchop it in a Buell way without altering the geometry of theframe, the front end length or lowering it, which is a tradition withour custom bikes. There’s more. We wanted the bike to sound more likea Harley and we wanted to enhance the performance without disturbingthe long-range reliability.

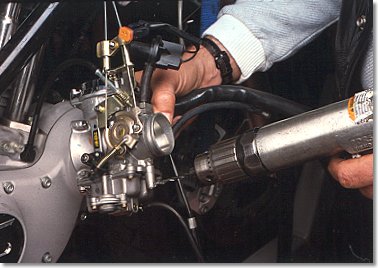

Our team included myself, Professor NuttBoy, consulting fromPaul Davis of Charlotte, Gene Tomasen Jr. from the Harley-Davidson fleet center, and a number of Bikernet readers who knew about and were testing Buells. This is the first of several techs on the modifications and the experiences we have with the M-2. We collected and ordered parts, then ran to the fleet center to get thejob done. The initial plan was to unleash the natural performance ofthe bike without breaking down the engine. We started by removing thecarburetor.

We replaced the needle in the slide with an ’88 Sportsterneedle, and drilled out the carb body above the idle adjustplug.

That allowed us to knock out the plug and back outthe idle adjuster 2.5 turns.

Stock carburetors are adjusted from thefactory to a very lean condition. Usually they are so lean that warmup takes a long time and you get an occasional cough through thecarb.

Others have recommended drilling directly through theplug, but Gene warned that if you slip, you will drillinto the adjuster screw and possibly damage it. Gene also recommendedhead work ultimately coupled with a 44 mm CV carb, manifold androller rockers in the future. I had a Screamin’ Eagle air box for a BigTwin, which I modified for the carb with an open K&N filter. We alsodropped the float bowel and replaced the 42 pilot jet with a 48. Becareful not to strip the screws holding the float bowel in place.Treat them with respect or they’ll cause you nightmares.

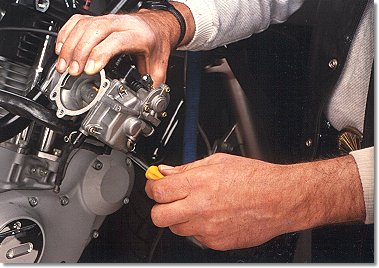

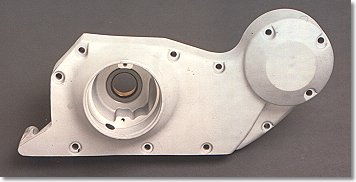

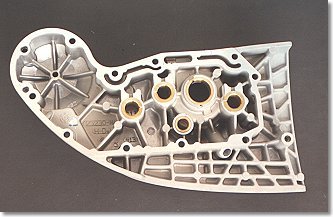

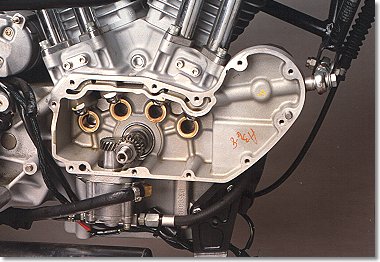

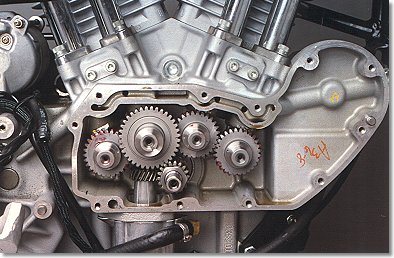

We set the carburetor aside and began to remove the timingcover to replace the cams. It’s important to take a scribe to thetiming plate so that you can duplicate the timing once you havereplaced the cams. Then pull the plate and the rotor cup, which isscrewed into the No. 2 cam. Before you go any further, remove the rockerboxes and the rocker arms to unload the tension on the non-adjustablepushrods. Now you can remove the cam cover, but don’t forget todrain the oil first.

At this point we decided to add a racy feature to theappearance of the bike by shaving the cam cover plate. First removethe oil line. Unplug the timing plate wire, dismantle the connectorand pull it through the plate.

Gene used a Sawzall and a grinder toremove the aluminum underneath the bolt holes.

You will note that there is a series of seemingly endless webbing in this area which is for noisereduction.

Notice that in the lower left hand corner, there is a dowelpin. Gene chose to leave it in place as a wiring guide and carve thecover around it.

The pushrods are color coded: pink or red forexhaust and brown for intake. The cams are numbered like you readfrom left to right, or back to front, 1 to 4. Make sure you pull theplugs for ease in turning the motor over. Install No. 4 first with redline assembly lube; No. 3 has two index marks. Slip No. 1 in next andNo. 2 last. It has three index marks to line up the cam with the pistonposition and the other cams with an index mark that aligns with aslot on the pinion gear.

This is where we noticed that the pitch onthe Screamin’ Eagle race cams was different than the new pinionshaft gears. An emergency run to Bartels H-D was in order for partNo. 24055-91, or No. 24061-91. The factory changed to a new pitch in ’99.When replacing the cam cover, keep in mind that there are fourdifferent length Allens holding it in place. Make sure you have theright length in the right hole. The torque setting for the cam coverAllens is 17 foot pounds. After the cover went back on, it was timeto reinstall the rotor cap and the timing plate.

These modifications will help it run better. Buells usually run hot from the factory because of hotter cams and ThunderstromHeads. At this point we re-ran the wiring to the regulator behindthe oil pump for a cleaner appearance. We only had to extend onewire, to the oil pressure switch. Gene Jr. handled it with solder andshrink tubing. Removal of the gastanks is a breeze and access to the heads and top end is easy. But ifyou need to remove the engine, the fact that it is an integral partof the frame and suspension creates unruly problems. The entirechassis must be supported.

At this point we replaced the pushrods from the top of theengine and replaced the stock rockerbox covers with chrome units.Don’t use anything on the self-sealing gaskets except a dab of greasehere and there to hold them in place.

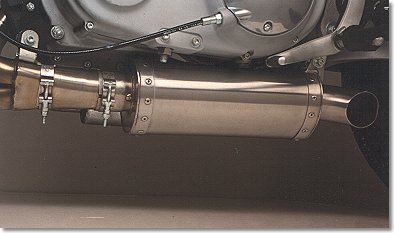

With the engine assembled, we replaced the stock exhaustwith a Buell race header kit and module. While Gene Jr. was out oftown, I spoke to the Buell tech of the demo fleet, Alan Varsi, who hasworked at Bartels Harley-Davidson for more than 11 years. The Buell racemodule retards the timing 5 degrees and eliminates the rev limiter.The stainless steel header is 11 inches longer than stock, which makeseach exhaust runner equal in length. The muffler is an aluminumcanister type that is high flow with low resistance for additionalperformance at the high end.

That’s it. Laughlin is right around the corner, along with our firstlong ride on the Harley-Davidson Street Fighter. We’re lookingforward to every desolate mile. We’ll report upon ourreturn. A new paint job is in the wings, along with some cosmetic modsto brighten the look of this bad-ass bike.

The Amazing Shrunken FXR Project

By Robin Technologies |

This here cardboard box full of odds and ends was where it allbegan. Or was it just an idea? Or maybe too much Jack Daniels. Ormaybe Bandit was tired of me whining about it. Anyway, like a beggar on the streets ofCalcutta, or Blanche Dubois in “A Street Car Named Desire,” I depend onthe kindness of strangers. And there ain’t none stranger than Bandit’scohorts. Strange but mighty generous, such as Rogue, who cut us adeal on the FXR frame and forks. We’re relying on Joker Machine forall the quality components including the end caps for the swingarmto get this puppy on two wheels.

We couldn’t figure out what this chopper was going to be. Maybe thedefinitive Rat Bike, or a stretched-out steel spider with a hellishV-Twin, or whatever kind of Rube Goldberg, slapped-togethermonstrosity we stumbled upon.

The critical thing is that I’ve got short arms and legs (kind oftroll-like) so whatever we made, it had to have a low center ofgravity. I tried riding Bandit’s Buell, but when I came to a stop, myfeet didn’t touch the ground. So we agreed that the frame had to damn nearscrape gravel. I kind of fancy myself an iconoclast, so I didn’t want tobecome another ad for yuppie motorcycling. Bandit wouldn’t let mepour acid on the thing to give it a lived-in look. If it was going to be a Rat Bike, heproclaimed with bombast, it had to be cool. Well, cool and twobucks might get ya’ a bottle of warm beer. I was determined to make my mark,rat-assed or not.

Bandit suggested that we chop a couple inches out of the frame.

OK, I sez. Bobbed fenders? Bob’s yer uncle, I sez. Narrow the fender railspace? Narrow it is, sez me. Now we’re rockin’. But to tell ya thetruth, it’s still a frame sittin’ in mid-air and a box full of used parts.

But don’t count us out yet. We’ve got a sizzling summer approaching,I’m outta work (I ain’t teachin’ summer school), the Jack Daniels is flowin’,and we’re fillin’ up more cardboard boxes. Bandit’s a tolerant guy, he’s gotthe summer (if he don’t go sailin’ off to the seven seas), and me? I got abrain bubblin’ like a pot o’ hot chili. No tellin’ where thiscrazy-assed bikeis gonna’ take us.

We threw the potentially radical chopper that Bandit and I have banged together up to this point, into the back of my pickup and jammed over to see the Doctor. Dr. John, the frame doctor took one look at the bike in the back of my truck and shook his head. Behind that scraggly beard and those beady blue eyes there is a wealth of experience. He’s seen a lot of biker hopes and dreams, sometimes nightmares, come through his Anaheim Hills shop. He’s managed to salvage most of them. His wry humor snuck through that tangle of beard, “Hmmm, that’s one nice looking Rev-Tech engine.” Bandit ground his jaw, I fidgeted, kicking at the asphalt.

He looked at our hopeful faces and didn’t want to disappoint, “Ok, I’ll take the challenge, but it’s going to take me a couple of days to figure out how the hell I’m going to hammer this thing into shape.” Bandit and I smiled, knowing that the Dr. was going to save our scrap-iron baby.

The whole idea was to shrink the Pro-Street frame around the engine, with just a slight additional rake to the front end. I’m 5’8″ but with short arms and legs, so we wanted the bike frame to be custom fit to my body- frame proportions. We had been looking at some of the bike designs from Japan (where the guys are built more like me) for inspiration.

Just with the modifications that Bandit and I have done so far gives some hint as to the unique feel of this design. With the massive Rev-Tech 88-inch engine and 6-speed Revtech transmission squeezed into place, it looks like a Star Wars space sled. I kind of like the rusty, unpainted Pro-Street frame. It gives it an elegant rat-bike look. But then that’s just my twisted sense of humor.

With the rubber-mount engine we have to leave some room for wiggle, so the frame can’t fit like Saran-Wrap. Cutting an inch or so off the swing arm will bring the back tire teasingly close to the inside-front of the swing arm. With a tiny back fender and stretched our front, the ass-end of the bike will look like it’s tucked in below the seat. I said it’s going to look like a running, weird-assed wild hyena. Bandit didn’t care for the comparison and shook his head discustedly.

When we built the Blue Flame, the whole bike was engineered to fit Bandit’s stretched-out body dimensions. Not every bike rider is built like that gangly orangutan, Bandit. So we’ve put a lot of thought into the design of this bike, in terms of scale and proportion. Even the choice and location of foot pegs, shifter, brake pedal, style of handle-bars, and primary shield, will reflect these concerns.

While the doctor is bending and welding the frame into shape, we will be working on paint design, tank and fender design, and ways to clean up some of the wiring, break lines and cables. Or maybe we’ll just fuck off until the doctor calls. Hey, it’s summer and we need to mellow out some.

The day started moderately okay. Bandit and I were going to zoom up toIrwindale to talk to Geoff Arnold at his Joker Machine headquarters to order a raft of parts for the Shrunken FXR, then toAnaheim Hills to meet John the Frame Doctor to check out the progress on myframe, we thought we might also catch lunch with Scooter, our notorious Bikernet criminal attorney, then a leisurelyglide back to San Pedro. No sweat, you say?

The closer we got to the foothills, the morning mist mixed with thecarbon monoxide of a million or so cars careening all over the L. A. basin.Ocean breezes pushed this toxic stew into the eastern edge of the foothills.By the time we got to Irwindale, the Bandit and I were like a couple ofbreakfast eggs sizzling in a skillet.

Bandit called the Doctor to confirm our plan to pop by. No way, no how,says the Doctor. He’s having a PMS kind of day. He hasn’t started on mybike. He’s got a hemorrhoid of a project to hammer out before he can starton mine. Dr. John also repairs sportbike frames and reported that sometimes the frames are so mangled that, well they should be shredded, not repaired. He was up against one of those. So no doctor visit.

A call to Scooter gets about the same results. He’s got to work so nolunch. The day was starting to feel cursed and doomed.

So we knock on the door of Joker Machine. On the other side of the doorwe could hear the banshee howling of an animal possessed. As we walked in,Studley the Joker mascot, attacked with teeth bared, an upper lip curled inschizoid disdain. The rabid Chihuahua snarled, yapped, barked and yelped ina psychotic frenzy. Damn near took Bandit’s arm off when he bent down to patthe little demon on the head.

Geoff grappled with the chain, holding back the crazed critter andwelcomed us with a hearty handshake. Geoff was a gracious host, showing usall the latest Joker products and a few of the Joker toys including their new truck.

Joker’s new Renegade traveling drag racing garage and party room.

Brian was outside welding together what appeared to be girders for abridge. It turned out to be the sturdy ramp superstructure for the improvedJoker Machine stationary Dyno. Like everything at Joker Machine, expertise andquality construction dominated. That’s one reason we chose to use Joker controls, footpegs and aircleaners and their new rocker covers. The blue flame was domintated with Joker components primarily due to fit and finish. Bandit has never purchased a Joker part and had to modify it to fit.

Secret Joker Dyno testing facility. What will they think of next?

Joker is in the process of developing a testing facility for a new line of products, yet to be released to the public.

Over lunch and beers we discussed our design ideas for the new bikesBandit and I are working on. The crew of Joker Machine looked at each othercautiously as Bandit babbled vague musings about “design integrity” and”hidden exhaust systems” or “creating a dense engine compartment.” I chimedin, gesturing with my hands, waving my arms to demonstrate the contours ofthe frame and tank.

Geoff grinned and said that he thought Joker Machine was up to the task.Bandit laughed and said that we had planned to integrate a number of JokerMachine products into our new bikes. Joker Machine, Bandit said, is the bikeparts distributor of choice. For example, he said, products like theadjustable foot pegs allow for adaptation to the individual rider needs.

In addition to the adjustable foot pegs, we intend to integrate into ourdesign with Joker Machine tear drop vents, hand controls and a Joker air cleaner. Weplan to modify Joker Machine forward foot controls to mid-controls.

The Joker Machine crew grudgingly finished their beers and got up toreturn to work. We all walked out side to a blast of heat that would curlthe devils eyelashes. Brian climbed into the back of a Joker truck housing a new V-Rod for product development. Brian recently graduated from advanced schooling in metal fabrication and the Joker crew is looking to him for inspiration and guidance into new product arenas while their CNC design wizard Richard continues to modify and develop new billet products.

Brian the Joker steel fabricator wizard pondering the V-Rod.

Bandit and I ordered everything from Joker point cover to forward controls that have zero slop, positive lever movement, built in stop light switch and adjustable foot pegs so you don’t vibrate off the pegs. They make all the difference in the world as Bandit attested to on his ride to Sturgis on the Blue Flame. We will doll up the Rev Tech black and chrome 88-inch engine with Joker Rockers that are fully machined from solid billet. The Wedge design enables total serviceability while the motor is in the frame. Bottom section is completely o-ringed. Base is clearanced for larger diameter valve springs and feature a unique modular baffle system for excellent venting characteristics. We’re also using their hand controls because according to Bandit they’re perfect. Our order contained a myriad of the little item also, like small triangular rear turn signals, mirror, gas cap, oil breather, throttle housing, billet clamps and bullet head bolt covers.

Finally we jumped into my truck and headed back tothe ribbon of shimmering hot asphalt of the 210 Freeway. By the time we gotto the 605 Freeway, it was 5:00PM and the Freeways were all at a turgidstandstill, constipated with lumbering gas guzzling, smog spewing cars andtrucks. It was one of those many moments when we wished we had those tight FXRs splitting lanes toward the cool salt air of the coast.

Doctor John promises to have the frame finished for pick-up next week. We’ll report from his Anahiem, Ca location.

If you’re in the Southern California neighborhood, Joker Machine is sponsoring a show at the Grand Opening of the Route 66 Roadhouse and Tavern, June 22 at 1846 E. Huntington Drive, Duarte, California. Call (626) 357-4210 for more information on the shows and Pig Roast.

My first concept drawing which Bandit puked on and shit-canned.

Here’s the first of one of my bumbling concept sketches. We will be working with a racing Porsche sheetmetal fabricator on fenders, tanks and exhaust configurations. Wait until you see what Bandit and I come up with next.

Like the enigmatic fortunes you find inside thosefolded Chinese cookies, our visit with Dr. John–the”frame doctor,” was a mix of New Age mysticism andpractical guidance. The week before, Bandit and Ibrought the rolling Pro-Street frame to the gooddoctor. We gave the him our best ideas of what wethought the bike should become. Basically, we wantedthe bike to fit my body proportions, to shrink theframe around the engine and to still have elements ofa street chopper.

Bandit and I had been trying to create a bike that hada real “signature” identity, yet we weren’t sure whatthat would mean. We tried to convey our concepts withawkward babbling.

Stroking his long, gray beard with a knowing gravity,the doctor calmly listened to our ravings. Eventuallyhe gave us a broad grin through the tangle of beardand said, “Don’t worry, boys, I understand exactlywhat you need.”

We had left the bike with vague misgivings.”Do you think he really has a clue what we want?” Iasked Bandit.

“I dunno,” Bandit said, staring off into the acrid,smog-laden sky.”The guy’s kind of strange, but everyone I’ve talkedto says the guy’s a wizard,” Bandit musedmysteriously.

When we pulled up to Dr. John’s shop, there was ourcreation leaning up against the wall. Not averse tostreet-corner poetry, I intoned, “What a bitchin’fuckin’-lookin’ bike.”

“Man, that bike is really unique,” Bandit exclaimed ina more civilized tone.

As we oohed and ahhed about the bike, Dr. John camearound the corner, grinning. I jumped onto theseat-less bike and grinned. It fit perfectly, betterthan an O.J. leather glove.

“I really think you’ve got something good goingthere,” the doctor spoke with unconcealedappreciation. “I wasn’t sure it was going to workuntil I got into it. The bike began to speak to me. Ithink it’s got the right karma,” the doctor spoke withmysterious gravity.

All this mystery was not without reason. Dr. Johnstarted this trek to ultimate frame adjustment workingat Goodyear Tires. A fortuitous opportunity, sponsoredby Goodyear, for advanced training at L.A. Trade Techgave him the chance to try motorcycle repair.Recognizing that he was more interested in bikes thantires, he began a course in bike repair withinstructor Pat Owens.

Dr. John soon connected up with a bike shop calledMotorcycle Menders. Right away, he could tell that hehad a better-than-average sense of what was needed tofix most frames. Eventually, he opened his first shopin Covina in 1983. In 1990, he moved to his presentlocation in Anaheim.

Dr. John’s expertise is extended to both traditionalstreet choppers and to the more exotic road racebikes, where competitive tolerances and alignmentshave seconds off of lap times. The challenges to hisexpertise in frame adjustment include the extremes ofcreating a bike for a 6’9″ rider and a Harley with a25″ over stock front end. For his own use, he isbuilding a karma-tingling three-wheeler with a VWengine.

In his shop, amongst a tangle of tweaked Ninjacarcasses, “destruction derby” ATV frames, twistedchopper forks and even a mangled Vespa body, Dr. Johnholds court. Side-tracking his stories about gettinginto the frame adjustment business, he mixes conceptsof metal stresses with ideas of mental stresses,Eastern philosophy, acupuncture points, shakras andauras, martial arts movements, elements of a good dietand muscle alignment of the spine.

The conversation stumbles easily into his personalexperiences. After an injury of his own, he explored avariety of methods of pain control, eventually meetingan American Indian psychic whose exotic beautyhypnotized him as much as her cosmic consciousness.Here, a glint comes to his eyes and a wry smile bringsone corner of his mouth up. “A rare beauty,” hemuses. “An aura just like Cleopatra of ancient Egypt.”

Bandit nodded in agreement repeatedly, like thoseDodger dolls that bobble in the back windows of cars,to the good doctor’s banter. Bandit slurped his greentea while listening to enchanting tales spun by theDoctor. While I shoveled in heaps of steaming andspicy-hot Kung Pao chicken, my eyes teared up and mynose started running.

“The magnetic flow is a flux of energy in the bodyof…” The steaming pots of green tea and plates ofexotic Chinese food sent wisps and tendrils dancing inthe air above our table like a chorus of swaying,sensual nymphets.

“The assorted colors of shakra balance…” Thisadventure had the aura of Zeke the Splooty about it.We were on a cosmic motorcycle Magical Mystery tour.

An hour or so later, Bandit and I were back on the 91Freeway with the bike strapped to the bed of hispickup, staring ahead kind of dumbly. “What a trip,Dr. John is,” I said.

“Yeah, but I think he did a great job on the frame,”Bandit said.

“Yeah, cosmic man,” my head was stuck in the ’60s.”What do we do now?” I asked.

“Let’s check out some trippy paint for the bike,”Bandit smiled. “Let’s drive down to Stanton and see ifWes at Venom can come up with something exotic enoughfor this mystery machine.”

“Go for it,” I laughed.

It’s days like these that make bike building seem likethe right thing to do. Bandit slapped in a tape of’60s funk and we were sailing down the road like acouple of latter-day Kerouac and Keseys.

“Hand me a bigger hammer, goddamn it,” Bandit hollered across the garage. We were slamming together as much steel as we could to get this Frankenstein of a bike together in time to show it to the crowds at the Queen Mary Motorcycle Show this weekend.So far this week we’ve managed to cut 1.5 inches off the swing arm. This brings the wheel into the back end of the bike at the point of the pivot. We are designing the bike with brevity in mind. We are hoping that the finished impression will be a bike shrunken around the RevTech 88-inch motor and Rev Tech 6-speed. Oh, we’ll have devilish accents here and there, but the overall concept is lean and mean.

To that end, we are cutting off any unnecessary tabs and struts. Of course, everything changes as soon as a UPS box arrives. Joker Machine parts arrive every couple of days. The foot controls arrived. The new front Avon tire should be here Monday or Tuesday. It arrived, we had it mounted pronto and the fender was looking good. I hauled it to Urs who is a master body man and he widened it to fit perfectly. Having the right tools makes a big damn difference.

A new front tire was called for because the sexy front fender from Cyril Huze was too narrow, since he builds bikes for 19 and 21-inch from wheels and we’re running an 18 (our fault).

After banging the hell out of the fender to try to squeeze out a fraction of an inch clearance, we decided on a smaller sized tire. We ordered an 18/ 100-90. We hope this will allow us at least 3/8-inch all around.

The new Cyril designed stretched tank arrived with the fenders. We cut out part of the bottom of the tank at the back where the front of the seat is, since every goddamn thing we do is backwards. Every builder in the country stretches bikes, we shrink ’em, so the tank won’t fit without mods. This move helped bring the tank down closer to the engine and since the FXR is short, well you get the picture. The tank tabs are in place and welded.

We decided to use an old rear fender off one of Bandit’s past bikes–a Fatboy. We turned it around backwards, the front end will be bolted to the center of the swing arm. Our next problem was how we were going to hold up the stern. After a lot of head scratching, cussing and phone calls we met with master fabricator James Famighetti who suggested that we create our own struts that will be bolted on the inside of the lower rear shock absorber bolt, then welded to the outside of the fender in such a way as to add to the over all look and strength of the fender and conceal the stock aspects. Mounting fenders to swingarms is treacherous. It will vibrate like a dog attacked by killer bees, so it better be strong and still able to remove for touchup.

No problem, you say? Ah, ha, not so easy kimosabe! We are pretty sure the strut will have enough clearance for the Rev-Tech brakes on the right side of the rear tire. When you come around to the left side, you’ve got the pully to contend with. So on this strut we added a 2″ dog leg to clear the pulley. I made up the patterns on cardboard and the Fam-Art brothers cut and bent the pieces. Then it was time to fit. We’re getting there.

The BDL pulley from CCI is smaller than the one we used for the mock up. So with our fingers crossed, when all these parts come together this week it will be amazing if they all fit. They did, well, perhaps not perfectly, but we’re getting close.They did, well, perhaps not perfectly, but we’re getting close. If not, “Bandit, get me a bigger hammer, goddamn it!”

Here’s the score. The fender needs tabs and it’s ready. The rear fender needs rivet removal and the massive tabs tack welded. The shock tabs have been cut since the Progressive Suspension shocks from Custom Chrome need to be set wider away from the fender tabs. Let’s see if we can make it to the show. We’re still waiting on Huze oil tank mounting tabs.

The saga of the Amazing Shrunken FXR continues. This project is notonethat is merely slapping together after-market products to build a facsimileof a customized Harley-Davidson.From the start, Bandit and I sought to create a unique ‘signature’ bike.Even though we have used a lot of after-market products, most have beenmodified to fit our design plan. The products we use, from the FXRPro-Street frame to the Rev-Tech engine to the Joker Machine qualitycomponents, to Cyril Huze, Avon and BDLare some of the finest products available.

Because some of the fundamental elements of design were modified, we havebeen constantly fabricating new brackets, tabs, mounts, and studs. Eachmodification created new issues relating to the fit and function of thedrivetrain. It seems as if we’ve bolted and unbolted the elements of this bike ahundred times.For example, the frame was modified by Dr. John to fit the Rev-Tech engineinto our overall design concept. The top motor mount was bent to fit thenewspacing. We used this motor mount point to position the Cyril Huze teardropgas tank. When we positioned the tank we related it to the handle barclearance at maximum turn position. Rubber mount brackets were welded inplace. The tank was cut at the underside back end to fit low on the frame.It looked hot. Next I cut the La Pere seat pan to hug the pointed rear ofthe gas tank and strengthened the seat back. There is a continuousdouble-‘swoop’from the handle bars to the back of the rear fender. The seat pan lookedhot.

Then we tried to put the engine in. It didn’t look fit. The engine wasmere fractions of an inch from fitting. Even if we could have hammered itinplace the subsequent tight tolerances would surely create problems as thebike rattled and roared down the road.

At this point, we cut the original tank brackets and repositioned themodified tank a little higher on the top frame tubing. The tank looked hot,the engine fit, but now the handle bar swing is a fraction of an inch tooclose to the tank. This means we will probably have to have custom handlebars.

It still looks good and we’re still optimistic. Even as wedroppedthe tank down on the new rubber mount brackets and began putting in the5/16″bolts, we found that the right rear bolt was too long to fit. So we got abolt with a thinner head and with my small fingers, I got the bolt in andstarted. We were still looking hot.

We decided to see if the belt fit since Bandit had cut andrewelded the swingarm 1.5 inches shorter for that Amazing Shrunkenlook. Bandit said no, the belt wouldn’t fit. It wasn’t suppose to. Isaid it looked close. As welooked at the bike we realized we’d had to remove the engine, drop thetransmission, which meant we’d have to support the swing arm. It alwaysseems harder than hell to make something easy. So with a couple of scissorsjacks, hunks of wood, and a crow bar, we were able to loosen the rubbermounton the left side of the pivot point of the swing arm. Then we gingerlyslipped the belt in, put the rubber mount back and bolted everything backtogether. Damn! It fit perfect and we were looking hot.

Wait a minute. The right side of the belt was almost touching the edgeofthe back fender. Quick surgery with a saws-all cut a chunk out of thefender. Fender fits, belt don’t rub, bike still looks hot.

As we cram more operational parts together, the room to move gets lessandless. Next we positioned the oil bag, which also brought up the issue ofthebattery accessibility. With bungee cords, a busted yard stick and some woodshims, we finally got the bag in what seemed a reasonable position. Fourrubber mounted brackets were fabricated then welded into place. It lookedHot. Everything was bolted in place. And everything looked Hot.

Ah, but not so fast kimosabe. We shaved the fins off the back ofthe oil bag for more clearance. With the two rubbermounts in place atthe rear of the oil bag under the seat pan we had enough clearancefor the battery, in the front for the engine and exhaust, under itfor the starter motor, but no clearance for the ever moving rearfender. It needed at least 1.5 inches of shock play since it’sattached to the swingarm. We had to peel the bag out of the frame andtake it to the Famighetti’s metal fab shop, Fam-Art, for theirexpertise. They came up with a plan to scoop out the back of the bagto the battery box without shortening the overall look of the bag.Then the fender will have the clearance to move with the swingarm andstill look hot.

Next, we neet to investigate whether the Joker controls canbe mounted mid frame. At the same time we will begin fabrication ofthe Amazing exhaust system. It’s gotta be lookin’ hot one way oranother.

Bandit and I were checking out the Amazing Shrunken FXR. “Thedamned thing,” referring to the shrunken FXR project we had beenhammering at, off and on, for almost two years, “has attitude,” hegrowled, “a bad-assed attitude.”

“Yeah, but will it have sound attitude?” I mused. “I want it toget attention. I want it to be felt in their chests before they seeit. I want them to hide their children from the evil they fear.”

The Amazing Shrunken FXR has developed into a mythic ethos. Froma cardboard box full of rejected, beat-up, and cast off parts, thebike has become a sculptured icon, a physical dream, and perhaps awrong turn down a bad dirt road, three miles back.The project began back in the spring of 2001. After a lot of fitsand starts, the Buell Project, the Sturgis Run, the Deer Gut stewadventure, Bandit’s painful recovery, the Red Ball prep, variousevents including a trip around the world and soiree’s, we slappedparts on, hammered steel into shape, welded this and that, cussed andfarted and got to where we are with the help of a RevTech driveline,Custom Chrome, BDL belt, Joker controls, Cyril Huze sheet metal andCompu-Fire electrics. The bike is raw boned, trimmed down, and meanlooking. That’s where it stands, inert and waiting for inspiration,up on the rack at the Bikernet garage.

Bandit regarded the raw metal frame with squinty-eyed intensity.”What you thinkin’,” I asked, keeping my own gaze focused on thepotential of the bike. At my question he stretched out his gangly,egret-like frame to its full 6’5″. “It’ll be a loud mother fuckereither way you play it,” he intoned in his gravitas basso-profundodeep voice. “We’ve shortened the frame and rear wheel base so muchthat it’s barely a cunt-hair from the exhaust port to the rear wheel.”

We cut a piece of an Samson Evolution system with a Mikita touse the exhaust port, then started welding other pieces in place. Wecut it back to make a tight turn and create space away from the oiltank.

“Fuck it,” I responded in my best Pancho Sanchezimprovisation, “let’s just start from the port and see what happens.”

We rummaged through a pile of Samson scrap exhaust pipes that wehad scavenged from a dumpster behind the Sampson factory. Flingingout fish tail tips, shot gun systems and swoopy cruiser exhausts,most of them dented and damaged so they couldn’t be re-used. Mr.Samson gave us only the best to modify. We eventually came up withenough pieces to fabricate a Frankenstein exhaust system.

As I grabbed for a section 1 3/4-inch chrome pipe, Imistakenly grabbed a goodly chunk of fur. Bandit’s midget, crazeddemon of a feral cat yeowled in protest and sank his needle-liketeeth into the back of my hand.

“God damn that crazy bastard,” I screamed, “he’s as crazyas a peach orchard boar.” I’m sure Bandit has a mescaline salt-lickfor that freaked out feline.After I extricated my hand from the jaws of Bandit’s feline Cujo, Ireturned to the exhaust system at hand.