Bikernet Project: Widowmaker Charity Build, Part 4

By Robin Technologies |

I cannot stress enough to plan ahead.

The best way to handle this is by drawing up your own wiring schematic, making a list of all the items you are using. This will give you a visual to go by. In our case we used the stock wiring harness, with some modifications to make everything work. Then we added a great product, “Grip Ace.”

The “Grip Ace” makes for a super clean and simple install without the dopey look of stock switch housings. If you are not familiar with this product, visit them at www.gripace.com. This product allows you to have all of your bike functions literally at your fingertips of your left hand. The system is compiled of a four button key pad that is installed on your left hand grip and a slim line module that can easily hidden almost anywhere on your bike.

The wiring is super simple. Once your left hand grip is fitted with the key pad, run your preformed wire and plug through your bars and plug into the module. All of your bike functions are wired to the module. The unit comes with clean and clear wiring instructions and easy to follow schematics. On our bike, we chose to keep the system super clean and mounted our key pad to the inside tunnel of the gas tank. As for the rest of your wiring, test each circuit as you assemble it. Try not to rely on butt connectors, solder as many of your wire connections as possible and keep in mind the serviceability of the bike. Make sure that future removal of the headlight and rear fender can be done by unplugging the wiring rather than cutting it.

Item Five: Last pieces of the puzzle, installation of the tins. This can be the most rewarding part of the job, seeing your new bike in all its glory or it can be a bad day and a trip back to the painter. Make sure you take your time in this installation. Make good choices of hardware. I personally like to use rubber washers on painted surfaces so as not damage the paint with the installation of the mounting hardware. Once everything is hooked up, top off your fluids and add only enough fuel to get the bike running. I suggest this in case there is a an issue of a gas leak or oil leak that may require you to remove the tank.

Once everything has checked out, get out and enjoy that first test ride. Make it short, come back, check everything over. Once all is good, pack up and enjoy your new ride.

THE CHOPPER OF CHOPPERS FOR SALE

By Robin Technologies |

This bike represents an upbeat era when choppers were kings and the Discovery Channel made it so.

We are going to attempt to tell the story of the bike, the shows, and the esteemed owner, Hugh “The Chopper” King, the producer/director.

Hugh actually worked for Easyriders, as the video editor/director, while I watched over the magazines. But he moved on to Original Productions. Motorcycle Mania was the first motorcycle show and I got a call. “Who should I recommend?” Dave Nichols asked. I said Jesse James, and the rest is history.

“Tom Beers, the boss of Original Productions, came to me,” Hugh said. “He asked me if I knew anything about motorcycles, and I said I knew everything about motorcycles, which of course I didn’t.”

“I had worked for one year at Easyriders, “Hugh continued, “doing Easyriders home videos, back when Keith Ball was the editor. These videos really captured the hard core, get down, biker lifestyle. So when Discovery came to us about a custom Harley show, I was all over it.”

The industry started flying and the ratings for these shows went through the roof. During filming at an Easyriders granddaddy bike show in Columbus, the Discovery Channel guys interviewed me and they asked what sorta chopper show I would suggest.

“Roger built his beautiful machine in honor of his daughter,” said Hugh, “who was killed on a motorcycle on the previous New Year’s Eve. It was very moving. His bikes are mean, man, and they run. The guys rode like bats out of hell, at over 100 mph a lot of the time, from Florida to North Carolina. At one point, Billy hit a big pothole, and flew so high into the air I thought we were going to lose him. That episode was really well received, which was enough for Discovery to order four more, and then seven after that, and 11 after that. There were a total of 44 Biker Build-offs.”

Hugh and I talked from time to time during the seasons. The flurry of action was high and the drive-by builders to be celebrities flew over the top. I remember riding my 2003 Road King to the Laughlin River Run. Hugh invited me to, I believe, the unveiling of this bike, but as usual, I got lost with a girl in the desert and never made it. While at Hot Bike, I attended with my crew one of the season finales to celebrate the builders and their accomplishment. The King presided over the festivities.

This chopper may end up on eBay, but if you’re seriously interested reach out to Hugh King at: hughk16@gmail.com.

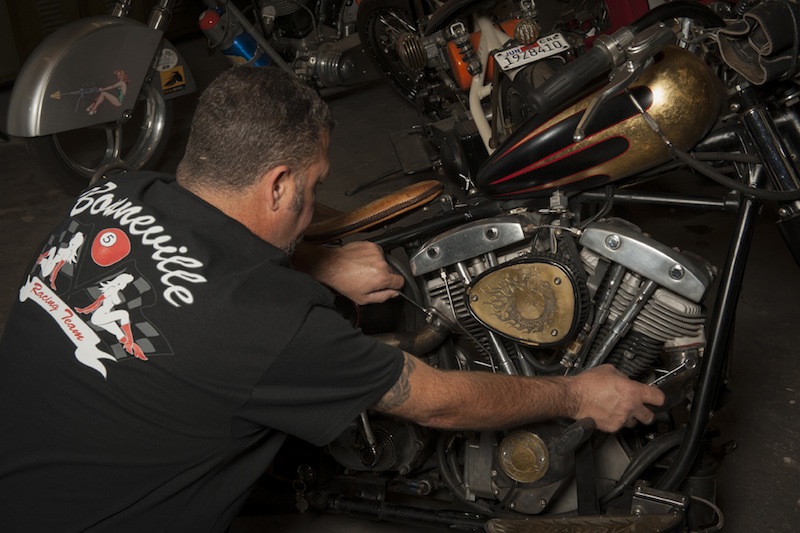

Doug Coffey’s RetroMod Panhead Part 3

By Robin Technologies |

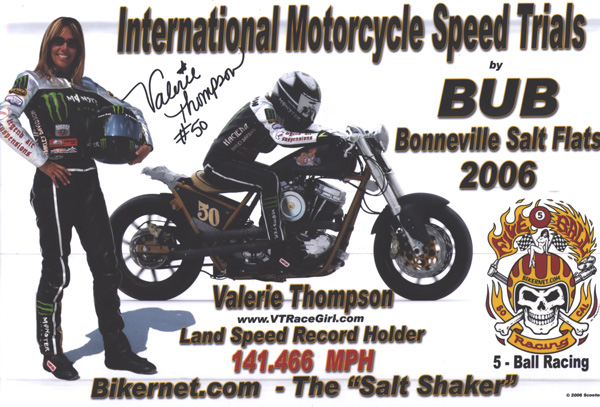

What the Hell is 5-Ball Racing?

By Robin Technologies |

Rebirth of an American Classic: Case Repairs

By Robin Technologies |

|

|

|||

|

|

|||

|

|

|||

|

|

|

The Mudflap Girl FXR Saga

By Robin Technologies |

It all started when a brother was desperate for cash and I bought a basket case Dyna, and with the help of JIMS machine turned it into an FXR. I started to build it for my son, Frank, the tattoo artist, around an old Kenny Boyce-styled pro street frame. Making progress on this build, with a massive upside down Custom Chrome front end, a brother stumbled into my shop and told me about Paul Cavallo and Spitfire Motorcycles.

Paul’s been around the industry for a couple of decades. When the economy tanked, he hung on with his dad and started Spitfire motorcycles. He was struggling and a brother thought I could help by using a couple of his Spitfire components on a Bikernet.com build. I went to visit Paul and was inspired by his non-stop drive to create new components daily, build world-class old school chops for customers, and kick ass at shows all over the country.

Then I was hit with the bike builder blues. My girlfriend left and I was forced to sell my 2003 Road King, leaving me with a ratty rigid Shovelhead and a Bonneville racer to ride. I needed a new girl and a long distance rider. Too often, around the campfire we debated twin cams versus Evos and most of the bros confirmed the solid stature of the FXR configuration. A plan formulated to build myself another FXR. I returned to Paul’s shop to cut a deal on a chassis for myself. Both were stretched, almost single-loop, long-distance riders with Spitfire Girder front ends.

Paul’s team built my chassis in pure traditional FXR style and Frank’s in the pro street configuration. We re-manned Frank’s FXR engine in black and chrome, and I ordered a bone-stock crate H-D 80-inch Evo. Both transmissions were rebuilt by the JIMS crew to be 6-speed overdrive units. I went with chain final drive and Frank used a stock belt.

The overwhelming concept revolved around building a bike that’s a chopper to the bone, but could be easily ridden across the country. My stretched gas tank holds well over three gallons, the oil tank contains nearly four quarts of oil, and I installed an oil cooler for heat waves. The Spitfire bars are held in place with Custom Cycle Engineering dog bone rubber-mounted classics.

I used Contrast Cut Performance Machine grips and pegs for style, yet road comfort. The bike is rubber-mounted for vibration-free riding. I worked closely with David Zemla of Progressive suspension until we configured a shock system capable of affording me some suspension with somewhat limited travel.

The girder is an uplifting quandary. With the Spitfire structure I could feasibly install almost any shock system, with whatever spring rate I decided on. I’m still messing with the gas-operated Rockshox.

I’m missing the best part, the Saddlemen seat. This seat was carefully configured at the Saddlemen manufacturing facility in Los Angeles, from the heavy-duty fiberglass seat pan to the spine-relieving slot, to the better than foam gel, and the ultimate breathing resilient fabric. That puppy is amazing.

The engine is virtually stock with the exception of a Bennett’s Performance-installed Andrews Cam, S&S oil breather gear, and Branch flowed heads, all their state-of-the-art valves and springs, and intake manifold. I ran an Andrews EV-27 cam and Andrews chrome-moly adjustable pushrods for less flex, a new cam bearing and the Branch flowed stock heads, for 8.9:1 compression, 78 cc Branch-flowed chambers, and 75-80 horses at 2,600 rpms.

The bike was built specifically for the road, but with chopper styling. I can’t leave anything alone, or ride a stock bike. It’s against my nature, but I can ride a scooter that will get me there comfortably in style.

For the first time in my bike-building life, I built this bike in bare form, wired it, and rode it for almost eight months. The benefits are immense, since I could make changes and adjustments throughout this road or rode research period. It gave me an extended period to investigate color schemes, build the front fender, break stuff, repair, and outright replace components, including my goofy chain guard.

It’s odd, but even with 2,000 miles under her belt, I still came up with last-minute changes during the paint and powder process. I added a keyless ignition system from Digital Dawg, which proved to be a safety and security feature. The drawback to riding a bare vehicle for an extended period included rust and oil management.

Still, when I assembled the bike for the final time, I ran into rear powder-coated fender expansion, and adjustments to the position of my one-off Spitfire oil bag to prevent chain damage. Maybe a rear belt would have been a wiser decision, maybe not.

Finally, the Mudflap Girl represents the open road. She represents the drawbacks of industry when it takes our girls away from us. And lastly she represents the desire to find our Mudflap Girl at home or down the road.

Name: Keith “Bandit” Ball

Owner: Lt. Ball

Builder: Ballintsky

Year, Make & Model: 2012 Mudflap Girl FXR

Assembly/Builder: Ballorama

Timeline: 8 months

Year/Model: 2012 Girder

Builder: Paul Cavallo, Spitfire Motorcycles

Type: Girder

Triple trees: Spitfire

Extension: 9 inches over stock

Year/Model: 2011 H-D

Rebuilder: New

Displacement: 80 cubic inches

Lower End: assembled by S&S

Balancing: S&S

Pistons: H-D

Cases: factory

Heads: Branch O’Keefe

Cams: Andrews

Lifters: S&S

EFI/ Carb: Trock modified CV

Air Cleaner: Roger Goldammer

Pipes: D&D

Ignition: Crane Hi-4

Year/Modifications: 2012 JIMS overdrive 6-speed

Engine sprocket: BDL

Trans sprocket: JIMS 23-tooth

Wheel sprocket: 51-tooth

Secondary drive: Biker’s Choice chain

Year: 2012

Designer/Builder: Paul Cavallo/Spitfire Motorcycles

Rake/Stretch: 5 inches up, 2 out

Bars: Spitfire

Risers: Custom Cycle Engineering dog bones

Fenders: Bar Knuckle/Toby/Bandit front, Biker’s Choice rear

Gas Tank: Biker’s Choice

Oil Tank: Spitfire

Headlight: Old spot

Taillight: Donkey from Biker’s Choice

Speedo: Wire Plus

Pegs: Performance Machine Contrast Cut

Electrics: Wire Plus, Digital Dawg (keyless), Biker’s Choice

Seat: Custom by Saddlemen

Front Wheel: Metalsport

Front Tire: Avon

Size: 19

Rear Wheel: Metalsport

Rear Tire: Avon

Size:

Hubs: Metalsport

Rotors: Metalsport

Brakes: GMA

PAINT

Bodywork/Molding: none

Painter: Chris Morrison and George the Wild Brush

Color: Super silver

Powdercoating: Worco silver and asphalt satin black

Biker’s Choice

BDL

Custom Cycle Engineering

D&D Exhaust

JIMS

MetalSport

S&S

Saddlemen

Spitfire

Wire Plus

J&P Cycles Giveaway Bike – Part One

By Robin Technologies |

Doug Coffey’s RetroMod Panhead Part 5

By Robin Technologies |

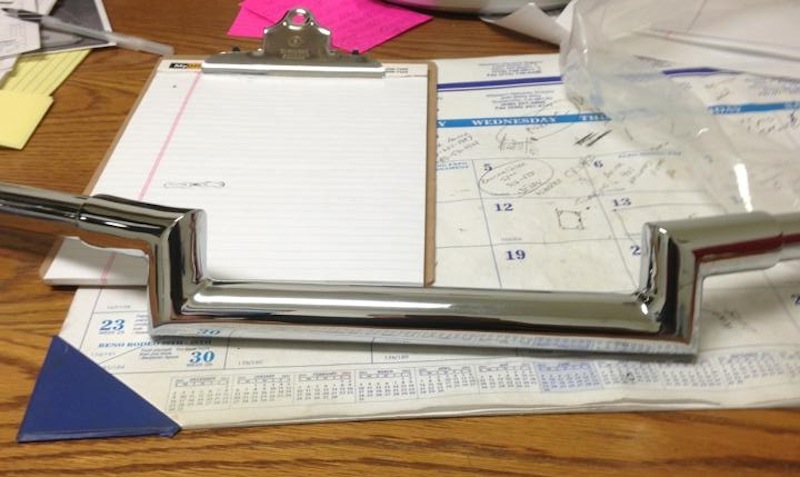

Risers

Doug Coffey’s RetroMod Panhead Part 1

By Robin Technologies |

Other than the missing sidecar sidecar loops, it has a strong resemblance to a 1957 straight leg rigid frame. Exactly what I wanted.

Bennett’s Performance 2004 Dyna Build 106-Incher

By Robin Technologies |

Eric Bennett grabbed the shop door chain and hoisted the roll up door for the first time, in 2000. He started his mechanical career as a certified diesel mechanic with 60-weight always flowing through his blood stream. Finally, he gave into his entrepreneurial spirit and his desire to make motorcycles his life—he opened his own shop on Signal Hill. The rest is motorcycle history, much of it spent at the Bonneville Salt Flats with his dad, Bob.

He recently owned a modified twin cam FLH, but a customer made him a deal he couldn’t refuse, so he let it go. Then a deal on a Dyna surfaced and he made a quick move to snatch it. This time, he decided he would take it to the concrete and rebuild every aspect of the bike to be moderately fast, ultimately reliable, precise, and built with absolutely all the best mechanical intentions and components in mind. You get to see the 106-inch project unfold before your very eyes right here.

One of the benefits of running a service center in the largest city in Los Angeles County includes encountering every possible mechanical malady and the ability to research whatever solution might be necessary. Since LA is also the motorcycle media hub, he has constant opportunities to test anything new on the market. After working on Twin Cams since their introduction into the market in 1998, Eric has watched every configuration, modification, performance recipe, and model roll in and out of his shop.

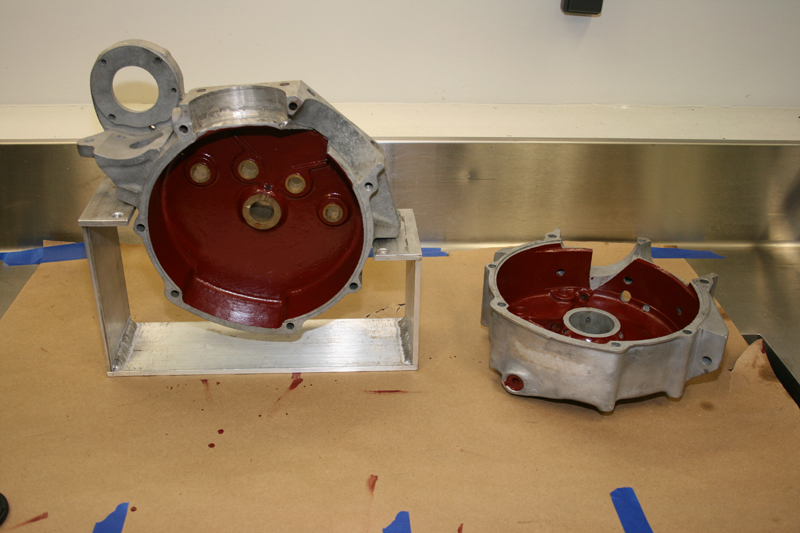

With this build he could pour every lesson and improvement into his own ride. It started as a bone stock 2004, 88 cubic inch TwinCam. Eric could choose from any hot rod configuration in the world, but he chose to roll with a 106-inch kit from S&S and Branch re-tuned heads. He started the process by installing a JIMS Timken conversion into his left case and welding his crankpin into the S&S lower end after it was balanced.

“With superior S&S flywheels, I didn’t need to monkey with the cases,” Eric said.

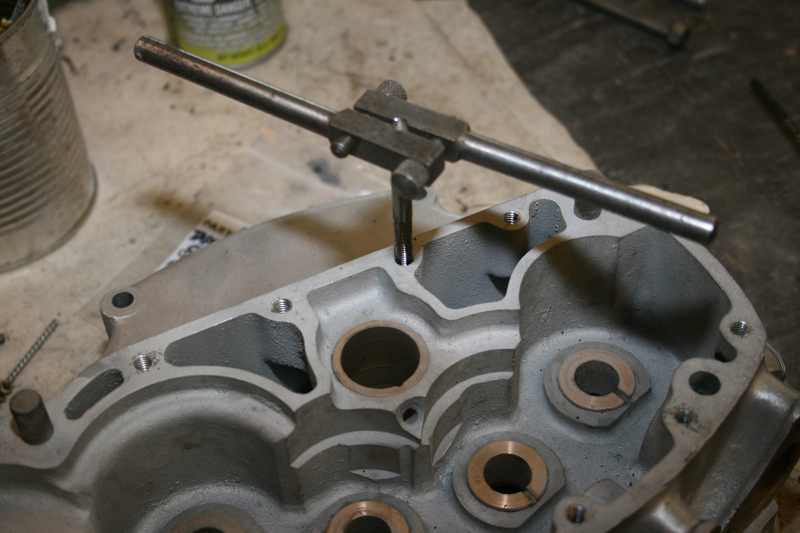

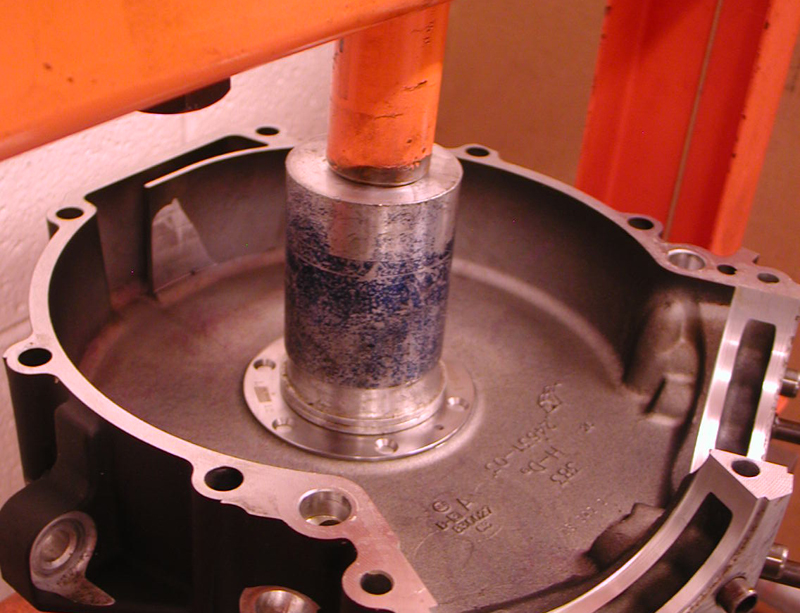

He bored the stock barrels from 3 ¾ to 3 7/8 inches and increased his stroke from 4 inches to 4.5. With JIMS tools he pressed in the JIMS race (using green Loctite) (9-59-1) while keeping his fixture perfectly flat and the hole in the race at 12 o’clock.

Using a JIMS fixture tool, he was able to drill guide holes in the case for Timken bearing and race oiling. The JIMS tool holds the drill and guides it. The drills are set to indicate the depth. Otherwise, he would need to use transfer punches and a milling machine. Then he used another JIMS tool to drill for the race fastener holes, and used tap guides to prevent misalignment.

“I’ve made tap guides for every size tap,” Eric said.

One of the benefits of the higher quality Timken lower end bearings is their ability to lock the lower-end into place.

“I have never seen a Timken bearing fail,” Eric said. Until recently Timken’s were used since 1957. “I’ve seen dozens of roller bearing failures!”

The cost saving shift to roller bearings started in 2003 during the 100th anniversary season. “The best Twin Cams were built in 2002,” Eric confirmed. “Better engines, still carbureted and with 1-inch axles for strength and stability.”

Eric used red Loctite on the race screws. He uses a tool for installing both Timken races at the same time. Kelly McKernnan, an amazing machinist out of Portland, Oregon, manufactured it.

The next phase included welding the S&S flywheels. Anytime Eric has a twin cam lower end out of a customer’s bike, he welds the crankpin in place with stainless TIG rod. It doesn’t create much heat and is not a structural weld; it just cements alignment and prevents shifting. He always checks the true after welding.

Next, he installed the Timken bearing by heating the race to expand it, and it slippped over the shaft easily. There is very little endplay in the shaft, just .001-.002-inch. Eric cinched down the top bearing with another JIMS tool, then pressed in the main seal and spacer with yet another JIMS tool.

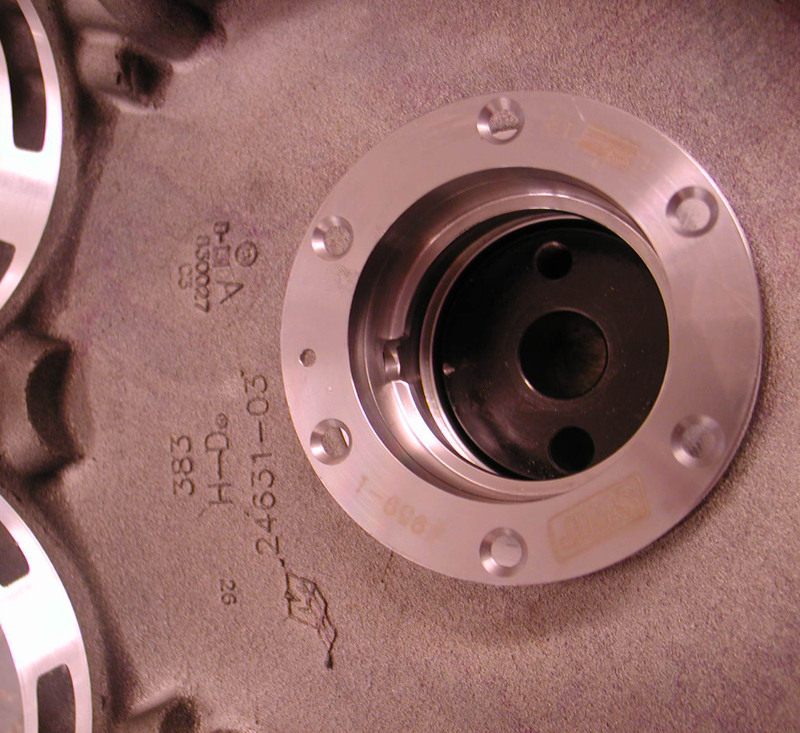

At this point, we shifted to pressing the new S&S cam bearings into the new heavy-duty Screamin’ Eagle cam plate for hydraulic cam tensioners, but Eric chose to shift to an S&S gear drive system, so he blocked off the oil passages to the hydraulics.

He installed Torrington cam bearings in the right case prior to installing the new cams. His plan called for installing a D&D Bob Cat exhaust system, which is 20 pounds lighter than a stock exhaust. D&D pipes come bolted together with all spring clips, flanges, and heat shields in place. “They take like two minutes to install,” Eric said.

“It’s the easiest system I have ever installed,” Eric said. “It comes with the all the components needed and the heat shields in place. No shimming is necessary or egg shaping holes.”

Day 2

We took a break for the day and grabbed a beer. But the next day, Eric installed a heavy duty Harley-Davidson pinion shaft bearing kit using a JIMS pinion bearing tool and it was time to slip the cases together with Yamabond on the case edge, while applying assembly lube on the pinion shaft. The case bolts were torqued to 18-22 ft. lb.

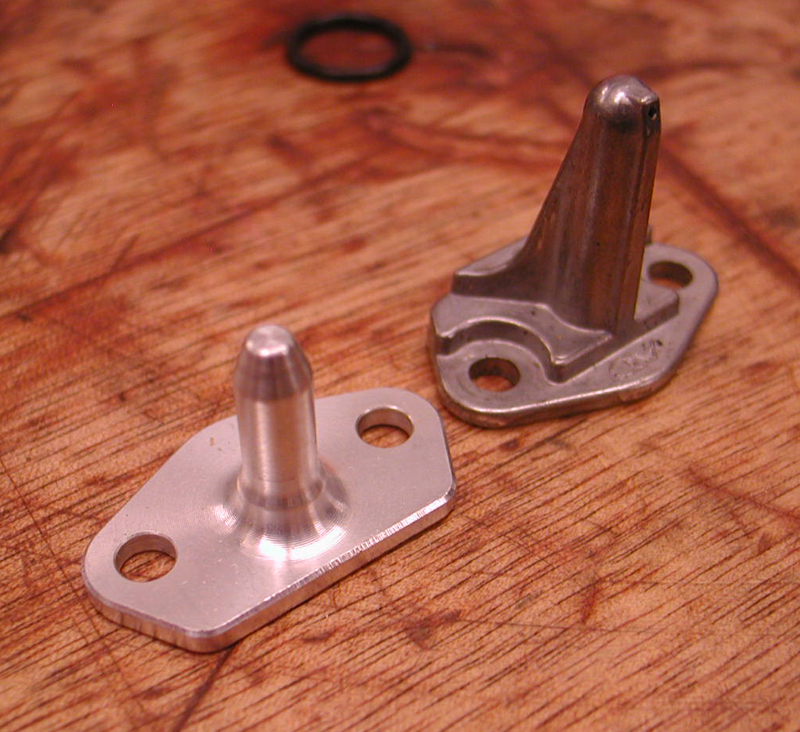

“Don’t forget the new oil pump O-ring when installing the high flow H-D pump,” Eric pointed out. Eric has an engine-building quirk. He continually turns the engine over, while rolling through the build process, and constantly tests for changes. “I want to catch anything that might bind early on,” Eric said. We actually ran into a small glitch while installing the cam plate.

But first, he installed the oil pump return gears, and then the separation washer and the spring, before the feed gear. He bolted the cam plate in place with ¼ -20 fasteners torqued to 120-inch- pounds. He used guide pins to help align the oil pump, and turned the engine over while tightening the pump so it would seat itself properly. He tightened two oil pump bolts, then removed the guide pins, and then tightened the other two Allens.

While aligning the cam drive gear dots, he installed the cams and used red Loctite on the drive gear Allen bolts, but used assembly lube on the washer for more accurate torque values and to prevent the bolt from galling against the washer surface for a false torque reading.

As we wrapped up the operation for the day, Eric installed the lifter with the oil holes facing the cam cover, then the guide pins, caskets and covers. No more lifter stools.

Day 3

Eric sub-leased a portion of his Signal Hill building to Branch O’Keefe, perhaps the best head porting business in California. I don’t want to put down any performance heads, but Jerry Branch, who is now about 82, built a helluva business around head performance.

Here’s a description of their heads from the Branch-O’Keefe site:

This is where is all began. Branch-O’Keefe is known throughout the industry for legendary cylinder head modification service. Our extensive reworking of stock Harley-Davidson cylinder heads begins with removal of the stock valve seats and guides. Next, the combustion chambers are heliarc welded to add additional aluminum alloy in the combustion chamber and around the valve seats for re-machining.

The valve seat pockets are then machined for larger nickel-chrome valve seats, and the combustion chamber is cut from the stock low compression rectangular shape to the legendary Branch “bathtub” chamber. After cutting the combustion chamber, new oversize valve seats and performance-quality valve guides are installed to tighter than stock tolerances.

The heads then advance to the porting room where the ports are fully hand-ported, blended and polished to Branch’s exacting specifications as proven on the dyno and flow bench. The head’s gasket surface is machined an additional 0.050-inch, which raises compression slightly. Finishing up, new oversize intake and exhaust valves (hard chrome stainless steel with stellite tips, polished face) are installed in bigger seats with a machined race-quality valve job and then hand-lapped. New seals and a high quality high-lift radius spring kit complete the installation.

The Branch O’Keefe head components are damn impressive from the titanium upper collars to the single oval wire spring with more travel and a larger diameter spring material. They have developed heads for JIMS big inch motors that produce 132 horsepower and ft-lb of torque, at an absolutely stock reliability level, even on a B motor. So natch, Eric had John O’Keefe and his master right-hand man, Paul go through his heads. Actually they used a formula they call the Dave Thew head. It’s a nickname for a performance formula. Dave beat everyone with these Branch O’Keefe head configuration. I will outline the different formulas next week.

We started the day installing S&S pistons with wrist pins first, since the oil rings pass over the wrist pin holes. Seems odd, but it’s the nature of the short-skirted piston. “Actually it allows for more skirt on stroker motors and does away with stroker plates,” Eric said. “This piston configuration will keep a stroker running longer.” The oil ring must be positioned with the dimple in the wrist pin area in a particular location to prevent rotation. The S&S pistons use four-piece oil rings with a removable ring land.

Eric installed the bottom compression ring so that the opening faced the exhaust port area. “No gaskets are used on the bottom of the cylinders,” Eric said, “just O-rings.” He compressed the rings carefully, lubed the inside of the freshly bored cylinder and slid the cylinder into place. Then Eric spun the motor over to check for binding. “I can’t wait to hear the D&D pipe.”

Eric started to install the heads using Cometic gaskets. The heads were torqued to Cometic specs and then he set to installing the rocker boxes and the fasteners, which were torqued to 22 foot-pounds. He started from the inside and worked out. Then he slipped in the S&S Quickee-Install intake pushrods for maximum valve opening. “I run premium S&S lifters with travel limiters,” Eric said. “They become solids at high RPMs.”

He tightened each pushrod until the valve slipped off the seat, and then let it bleed down, for about 10 minutes. He backed off the adjustment until he could spin each pushrod (one at a time). Then he backed off just one complete turn or six flats.

These shots were taken before John O’Keefe came up with a crazy notion to machine Twin Cam cylinder fins in a round configuration. Eric was knocked out by the procedure and pulled his barrels for the process.

In the next episode, Eric will slip the beautiful 106-inch Twin Cam into the stock frame, and we will discuss JIMS tools, while replacing the inner primary bearings, the slightly modified Dyna D&D pipe, and then and the new Rivera Primo clutch, the S&S G carb, and a new S&S high flow air cleaners.

Sources:

Bennett’s Performance

S&S

JIMS