Classic rigid frames are more in demand than ever. If you’re going to build a chopper is needs to be carefully installed in a stock frame or die trying. Here’s the catch. Stock rigid frames are rare or are they? And now, more than ever you can have a frame looking totally classic without being stock. Confusing?

Depends on the Harley motorcycle segment you hang out in. I know lots of AMCA guys, Antique Motorcycle Club of America. Those guys still search for bone stock frames. Not just stock but the frame year matching the motor, trans and every other component involved in the build.

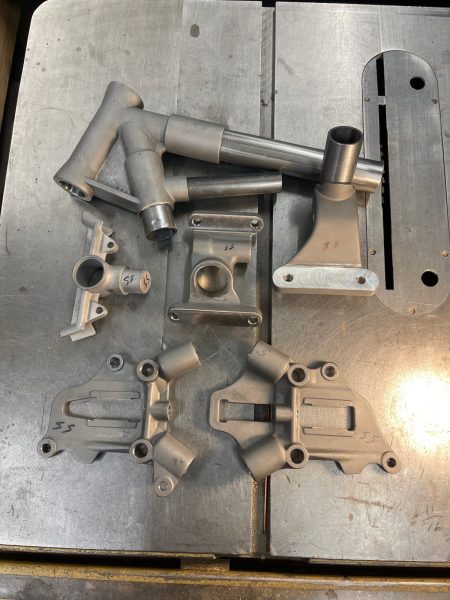

In some cases, a damaged frame is rebuilt using components cast by John Grant at Hardtail Choppers. If you find a bent or wrecked Knucklehead frame it can now be salvaged by a handful of guys with the gigs and frame tables necessary. There are more talents, but I have personally worked with Irish Rich in Sturgis and Doc John in Orange County, California.

There’s another trend surrounding the notion of stock frames in the chopper industry. I find this sorta whacky, but there is a serious trend toward the purest chopper builder. Two builders come to mind Micah McCloskey and Paul Wheeler.

Micah builds beautiful choppers around the original choppers built in the ‘60s and ‘70s. His creations are better looking and more refined than most of the bikes from those eras. During the kick-off of the chopper industry, guys stripped Harleys and built what they could with the resources at hand, which were severely limited.

The industry exploded around Easyriders magazine and new products popped onto the market constantly. Being a purest chopper builder is sort of an oxymoron. The pure notion of the chopper is to change, alter, weld, machine and generally fuck with a stock Harley until you make it your own. And fuck anyone who doesn’t like it.

So, John at Hardtail Choppers entered the foundry realm to save stock rigid frames. But no one likes pure stock, well almost no one. As his market grew his casting abilities expanded. He could make you a seemingly stock neck but with whatever rake you chose. Then he built single downtube necks and front motor-mounts. He also could make stock looking castings out of Stainless steel.

“I love to make stuff no one else has or can build,” John told me. He also told me a story from his childhood. He discovered a 1948 black and white cruiser positioned on the outskirts of his Vancouver, Washington town near a boulevard stop. When someone blew the stop, the cruiser cop signaled to the patrol officers on 1948 Panheads.

John watched as the cops kicked their first-year Panheads to life and peeled after the lawbreakers. He love it, and checked out the corner often, waiting anxiously behind a tree, for a perpetrator to blow the signal, so he could watch the uniformed officers kick the Panheads to life and listen to the crisp rumble of the Harleys peeling out.

Meanwhile back in the Hardtail Choppers Lab, John went to work recreating stock castings. Fab Kevin was one of John’s first customers and has purchased 300-400 H-D axle plates over the years.

Irish Rich, who escaped Colorado for the land of freedom in South Dakota sent a set of stock shock mounts from an early Panhead swingarm frame to John. These were pre-electric start and the frames were basically rigid frames minus the rear section. John needed to replicate them because of Jeff Cochran’s, at Speed Kings, demand to be able to lower swingarm frames.

Many of these castings came with solid slugs for mating them to frames. Over time Rich and other builders discovered machined tubing to be more flexible and prevent cracks in the frame tubing.

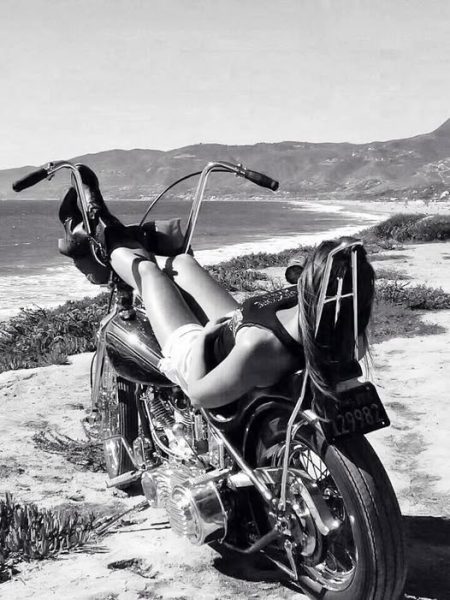

The frame inspiring this article set neatly on Irish Rich’s frame table in his Sturgis, SD shop when I arrived in my ’58 Belair. Originally a 1972 Harley frame, it turned out to be the last year of the juice drum brake configuration.

Rich added a Krispy Choppers Shovelhead Weld-On Hardtail with Hardtail Choppers Cast Axle plates and seat junction castings to complete the rear section.

Here’s the Krispy Choppers description:

We’re cooking these up daily, but depending on demand, they can take up to 2 weeks to ship. Get your order in early and lock in your spot.

This is how you do it. The cleanest, most dialed way to hardtail your ’66–’84 Shovelhead swingarm frame—no weird stretches, no chopped-up geometry, no guessing games. Just a proper Panhead-style tail section that bolts in smooth and keeps your VIN right where it belongs.

This setup runs replica cast axle plates and a cast seat post yoke. They are whipped up in the USA just like the factory used to do it. Rear trans posts are threaded, the lines stay lean, and everything is TIG welded in-house in Northern California.

No frame jig? No stress. You don’t technically need one, but they’re always a plus. This kit is designed to go in easy and lock up tight—so you can get back to building ASAP.

Why it rules:

OG Panhead-style geometry—no stretch, no rise, no drama

Replica cast axle plates + seat post yoke made by HCI in the PNW

Fully TIG welded + assembled in Northern California

Slugged top tube for a clean graft

1-1/8″ DOM lower rails match stock frame tubing

Chain clearance built in with a subtle kick-out on the drive side

Designed to preserve your factory VIN—so the DMV stays outta your business

What’s in the box:

Weld-on hardtail section

(2) Bottom rail slugs

(1) Rear transmission weld-on support

Fitment:

Fits factory Harley-Davidson swingarm frames from 1966–1984

Designed around 4-speed transmissions

Running a starter? You may need to check clearance on early horseshoe tanks

Install Tips:

You’ll need to cut out the stock seat post area and graft in the new section. Our top tube is pre-bent, slugged, and ready to slide in just ahead of the original seat post casting. The rails taper like a Panhead for that narrow, vintage silhouette. Everything’s sized and shaped to match stock tubing—no weird fitment or steps.

Check out our cutting diagrams in the photos to get a clear look at where and how to trim your frame. This one’s all about keeping it classic and making your life easier.

Need a ¾-inch axle setup? Grab our Axle Kit.

Got a 4-speed? Don’t miss our Transmission Plate.

John Grant at Hardtail Choppers continued working with his local foundry to cast necks without the gusset in the center. There are more, even these castings to build handlebars of any configuration.

Single downtube necks in 30-degree rake are now available. Single downtube front motor mounts are in stock. They are available in mild steel or stainless. John also has numbered footboard mounts and single downtube motor-mounts.

If you want something special, don’t hesitate to reach out. John can do anything, but it might take extra time.

SOURCES

HARDTAIL CHOPPERS

john@hardtailchoppers.com

Shop # 360-750 6780

www.hardtailchoppers.com

Vancouver, Washington

KRISPY CHOPPERS

Hit us up at info@krispychoppers.com for a proper quote.

www.krispychoppers.com

Located in Northern, California

SPEED KING

Support@speed-kingscycle.com

951-575-0093

www.speed-kingscycle.com

West Harrison, Indiana

SHAMROCKS FABRICATIONS

Irishrichryan@gmail.com

FAB KEVIN

586-291-4798

Clinton Township, MI 48036

www.fabkevin.com