The Mudflap Girl FXR Saga

By Bandit |

It all started when a brother was desperate for cash and I bought a basket case Dyna, and with the help of JIMS machine turned it into an FXR. I started to build it for my son, Frank, the tattoo artist, around an old Kenny Boyce-styled pro street frame. Making progress on this build, with a massive upside down Custom Chrome front end, a brother stumbled into my shop and told me about Paul Cavallo and Spitfire Motorcycles.

Paul’s been around the industry for a couple of decades. When the economy tanked, he hung on with his dad and started Spitfire motorcycles. He was struggling and a brother thought I could help by using a couple of his Spitfire components on a Bikernet.com build. I went to visit Paul and was inspired by his non-stop drive to create new components daily, build world-class old school chops for customers, and kick ass at shows all over the country.

Then I was hit with the bike builder blues. My girlfriend left and I was forced to sell my 2003 Road King, leaving me with a ratty rigid Shovelhead and a Bonneville racer to ride. I needed a new girl and a long distance rider. Too often, around the campfire we debated twin cams versus Evos and most of the bros confirmed the solid stature of the FXR configuration. A plan formulated to build myself another FXR. I returned to Paul’s shop to cut a deal on a chassis for myself. Both were stretched, almost single-loop, long-distance riders with Spitfire Girder front ends.

Paul’s team built my chassis in pure traditional FXR style and Frank’s in the pro street configuration. We re-manned Frank’s FXR engine in black and chrome, and I ordered a bone-stock crate H-D 80-inch Evo. Both transmissions were rebuilt by the JIMS crew to be 6-speed overdrive units. I went with chain final drive and Frank used a stock belt.

The overwhelming concept revolved around building a bike that’s a chopper to the bone, but could be easily ridden across the country. My stretched gas tank holds well over three gallons, the oil tank contains nearly four quarts of oil, and I installed an oil cooler for heat waves. The Spitfire bars are held in place with Custom Cycle Engineering dog bone rubber-mounted classics.

I used Contrast Cut Performance Machine grips and pegs for style, yet road comfort. The bike is rubber-mounted for vibration-free riding. I worked closely with David Zemla of Progressive suspension until we configured a shock system capable of affording me some suspension with somewhat limited travel.

The girder is an uplifting quandary. With the Spitfire structure I could feasibly install almost any shock system, with whatever spring rate I decided on. I’m still messing with the gas-operated Rockshox.

I’m missing the best part, the Saddlemen seat. This seat was carefully configured at the Saddlemen manufacturing facility in Los Angeles, from the heavy-duty fiberglass seat pan to the spine-relieving slot, to the better than foam gel, and the ultimate breathing resilient fabric. That puppy is amazing.

The engine is virtually stock with the exception of a Bennett’s Performance-installed Andrews Cam, S&S oil breather gear, and Branch flowed heads, all their state-of-the-art valves and springs, and intake manifold. I ran an Andrews EV-27 cam and Andrews chrome-moly adjustable pushrods for less flex, a new cam bearing and the Branch flowed stock heads, for 8.9:1 compression, 78 cc Branch-flowed chambers, and 75-80 horses at 2,600 rpms.

The bike was built specifically for the road, but with chopper styling. I can’t leave anything alone, or ride a stock bike. It’s against my nature, but I can ride a scooter that will get me there comfortably in style.

For the first time in my bike-building life, I built this bike in bare form, wired it, and rode it for almost eight months. The benefits are immense, since I could make changes and adjustments throughout this road or rode research period. It gave me an extended period to investigate color schemes, build the front fender, break stuff, repair, and outright replace components, including my goofy chain guard.

It’s odd, but even with 2,000 miles under her belt, I still came up with last-minute changes during the paint and powder process. I added a keyless ignition system from Digital Dawg, which proved to be a safety and security feature. The drawback to riding a bare vehicle for an extended period included rust and oil management.

Still, when I assembled the bike for the final time, I ran into rear powder-coated fender expansion, and adjustments to the position of my one-off Spitfire oil bag to prevent chain damage. Maybe a rear belt would have been a wiser decision, maybe not.

Finally, the Mudflap Girl represents the open road. She represents the drawbacks of industry when it takes our girls away from us. And lastly she represents the desire to find our Mudflap Girl at home or down the road.

Owner: Lt. Ball

Builder: Ballintsky

Assembly/Builder: Ballorama

Timeline: 8 months

Builder: Paul Cavallo, Spitfire Motorcycles

Type: Girder

Triple trees: Spitfire

Extension: 9 inches over stock

Rebuilder: New

Displacement: 80 cubic inches

Lower End: assembled by S&S

Balancing: S&S

Pistons: H-D

Cases: factory

Heads: Branch O’Keefe

Cams: Andrews

Lifters: S&S

EFI/ Carb: Trock modified CV

Air Cleaner: Roger Goldammer

Pipes: D&D

Ignition: Crane Hi-4

Engine sprocket: BDL

Trans sprocket: JIMS 23-tooth

Wheel sprocket: 51-tooth

Secondary drive: Biker’s Choice chain

Designer/Builder: Paul Cavallo/Spitfire Motorcycles

Rake/Stretch: 5 inches up, 2 out

Risers: Custom Cycle Engineering dog bones

Fenders: Bar Knuckle/Toby/Bandit front, Biker’s Choice rear

Gas Tank: Biker’s Choice

Oil Tank: Spitfire

Headlight: Old spot

Taillight: Donkey from Biker’s Choice

Speedo: Wire Plus

Pegs: Performance Machine Contrast Cut

Electrics: Wire Plus, Digital Dawg (keyless), Biker’s Choice

Seat: Custom by Saddlemen

Front Tire: Avon

Size: 19

Rear Wheel: Metalsport

Rear Tire: Avon

Size:

Hubs: Metalsport

Rotors: Metalsport

Brakes: GMA

PAINT

Bodywork/Molding: none

Painter: Chris Morrison and George the Wild Brush

Color: Super silver

Powdercoating: Worco silver and asphalt satin black

BDL

Custom Cycle Engineering

D&D Exhaust

JIMS

MetalSport

S&S

Saddlemen

Spitfire

Wire Plus

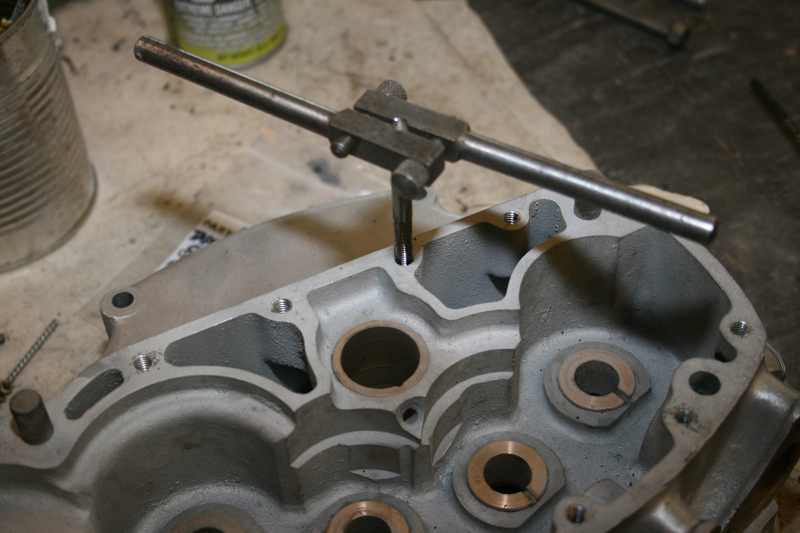

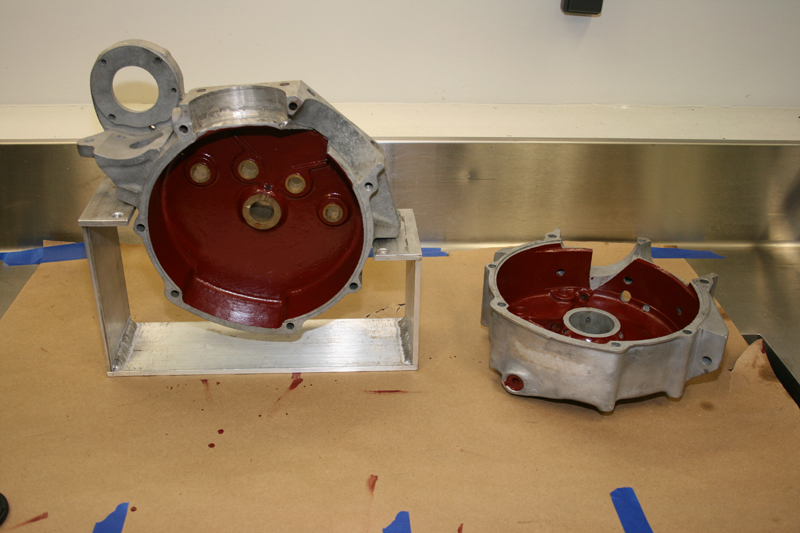

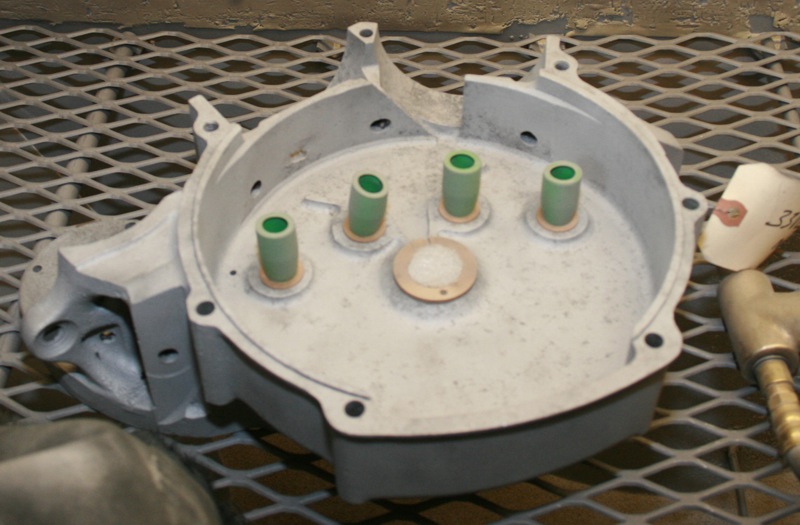

Rebirth of an American Classic: Case Repairs

By Bandit |

|

|

|||

|

|

|||

|

|

|||

|

|

|

The Amazing SHRUNKEN FXR Updated

By Bandit |

Once upon a time there was a bike built called the Shrunken FXR. Keith “Bandit” Ball, of Bikernet and other assorted fame, built it. By a stroke of good fortune the bike became mine through the generosity and trust of Keith Ball.

This bike was my daily commuter for a handful of years. It was and is always a challenge and a ton of fun navigating the streets and freeways of Los Angeles on two wheels and especially on a custom built motorcycle.

I decided it was time to update the look of the bike as well as do some fine-tuning of a few mechanical items I wanted to switch up a bit. Below is a brief summary of what was done, again primarily with the help of friends and some extra cash from my Pops to help get it all finished up proper.

First I replaced the front fork tubes with new fork tubes made by Forking by Frank. Styles have changes, so I installed new handlebars, 10-inch baby apes mated to Black Boyd Motor Co. risers.

I work at the magnificent ARCH motorcycle company and LA Chop Rods, so natch; I installed Black Anodized hand controls by ISR purchased. They are absolutely the best and contain the mechanical Bandit approved styling.

I replaced the mirrors with 2-inch Blind spot jobs by CRG (Small and work great). We

Powder-coated the classic Performance machine wheels black (Thanks to Custom Metal Finishing in Gardena CA, who handle the high-end ARCH motorcycle extreme perfectionist coating).

We manufactured a new Shift arm and Brake arm to improve function. Ryan Boyd, Boyd Motor Co./Arch Motorcycle, is a master machinist and engineer. He configured then machined these components to enhance the rear brake functions, and it now works like a charm, plus it improved shifting dramatically.

We replaced the pegs with something sport bike like and again Ryan stepped up to design and machine one-off mounting bracket adaptors.

We reworked the exhaust basically back to the original first version, added BBQ paint and LA County Chop Rods baffles.

These upgrades, in addition to the rear shocks by Progressive and my comfy Saddlemen seat make the Shrunken FXR road ready and looking fresh for 2016.

Me owning this bike and updating would not be possible without the help and kindness of the following wonderful humans beings: Keith “Bandit” Ball, Dr. Ladd Terry, Gard Hollinger, Ryan Boyd, Jose Laguna, Saddlemen, L.A. County Chop rods, Custom Metal Finishing, Boyd Motor Co., Frank’s maintenance and engineering.

Here’s a link to the original feature, if you search the Shrunken FXR on Bikernet, you’ll find all the build articles: http://www.bikernet.com/pages/Amazing_Shrunken_FXRThe_Full_Feature.aspx

–Buster Cates

The Magnificent ARCH motorcycle factory

LA Chop Rods

Saddlemen

BDL

Progressive Suspension

Rebirth of an American Classic: The Build Begins

By Bandit |

|

|

|||

|

|

|||

|

|

|||

|

|

Sturgis Shovel Gets A Wrap

By Robin Technologies |

VHT FLAMEPROOF COATING

VHT FlameProof Coating will renew and extend the life of any surface exposed to extremely high temperatures. This unique coating is a matte finish, silicone ceramic base widely used by the automotive industry on exhaust systems and the aerospace industry for jet engines, re-entry vehicles and other high temperature applications. VHT FlameProof Coating will withstand temperatures up to 2000°F (1093°C) and is ideal for use on headers, exhaust systems, or wherever an extreme temperature coating is needed.

Applications: Headers, Exhaust Manifolds, Piston Domes, Inside Heads

VHT FLAMEPROOF COATING does require curing and VHT includes some specific instructions on how to do this.

Curing FlameProof

VHT FlameProof Coating only attains its unique properties after correct curing (refer to instructions on the can).

Paint must be completely dry before curing

Heat to 250°F (121°C) for 30 minutes

Cool for 30 minutes

Heat to 400°F (204°C) for 30 minutes

Cool for 30 minutes

Caution: Do not exceed the temperature of the least heat tolerant component or the base metal

Paint must be completely dry before curing

Run at idle for 10 minutes

Cool for 20 minutes

Run at idle for 20 minutes

Cool for 20 minutes

Once I finished painting and curing(?) the exhaust pipe, it was time to get wrapping. J&P Cycles has a large selection of exhaust wrap to choose from in their online catalog and after looking at all the different options I decided to order the Design Engineering Inc, Titanium Exhaust Wrap Part #308-159. I also had them throw in a package of DEI’s 8-inch Stainless Steel tie wraps to secure the ends.

•Promotes increased flow for improved performance

•Reduces temperature & vibration breakdown

•Extremely pliable for a tight and secure wrap

•DEI HT Silicone Coating not required

•Pre-wetting roll not necessary for wrapping

•Hi-tech carbon fiber look

As usual my order from J&P Cycles showed up almost as fast as I hit the enter key on the order form. Once the wrap arrived I looked over DEI’s directions and proceeded to start wrapping the pipe.

Atomic Bob Original Art for Sale at Atomic Bob Shop

By Bandit |

I got on the horn with Atomic Bob to ask him to donate some art for the upcoming Flying Piston Benefit online auction in Daytona on March 4, 2024.

Instead of answering the question, Bob growled about those thieving sonsabitches hacking his Instagram account and were digitally squatting on his property.

He can’t DM, he can’t post directly, and he can’t get it back through Instagram. And the thieves want 250 hostage money!

I said, “250K?”

No, $250 and I won’t pay it. If I find them, they won’t do it again! After he got that off his chest, we discussed his new store. He’s now offering his original masterpieces at the Atomic Bob Shop on Facebook. And here’s a kicker—he’s drawing inspiration from the vibrant 2000s era!

2000s? During this time, Atomic Bob lived his best life with zero worries. Picture this: motorcycles, cars, cash—anything he fancied, he had it.

With a grin, the Atomic One shared, “Those were the days!”

.jpg)

Apparently, he use to embrace a perpetual cloud of smoke because, hey, who cared? “I was in my 20s, living the dream. But then I thought I should be a responsible adult and stick to legal stuff—like being an alcoholic,” he chuckled…

Ah, the Atomic Bob wisdom!

Atomic has since put the whiskey down and picked up the pipe. Since Ohio is now a cannabis state, he likes to kick back, relax and paint high.

If you haven’t seen Atomic Bob’s artistic style, then you are in for a treat. He seamlessly blends pinstriping, custom paint and illustration with a distinctive touch. Renowned for his imaginative creations, Atomic Bob’s art frequently features themes revolving around monsters and eyeballs, adding a unique and captivating flair to his work.

Bob then took me through a couple of his works in his Atomic Bob Store.

The first piece of art originated in 2014, was completed in Atomic Bob’s grandma and grandpa’s basement. His girlfriend Kelly had kicked him out for the last time and got him locked up as well.

.jpg)

“I was feeling down as I paged through a magazine and saw this T-Bird,” explained Atomic. “I had this building down by the railroad tracks. I decided I was going to call it Atomic Dice Custom Paint. This T-Bird was going to be my new logo. I remember I was mad because I had to start my life over yet again, get sober and blah, blah, blah.”

The T-Bird was drawn in-between fights and arguments and all kinds of chaos, including yelling and smoking cigarettes late into the night.

“The lucky boy or girl out there who gets this can honestly light it on fire and dance naked in the dark,” said Bob.

Another interesting piece is an original autobiographical art piece of Atomic Bob’s ‘51 DeSoto. His lead sled was slammed with exhaust coming out of the rear quarter panel.

This framed piece fell on his head when the cops came to arrest him, while slamming him against the wall. He reframed it, of course, but you can still see little slices in the parchment where the cops stepped on the art.

“When you’re an alcoholic for so long as I was, there’s a lot of moments I missed. I actually stare at things in order for shit to start to come back to me,” explained Atomic.

And that’s where the story gets cool. So, when somebody buys this, it will be like, “Oh man, the artists got arrested, the damn thing fell on him, and it was stomped by a cop. What’s not to like?”

“So, I’m living in the 2000s with my music. Feeling the good vibes. Smoking pot and taking care of myself,” Bob said. “I am grateful for what I have. I’m not abusing my body.”

“The medical industry might be able to fix me, but I can tell you right now, I’m not going to make it worse because I ultimately have to make money with my hands and my arms and everything.”

BIG FRIG – https://bigfrig.com/

FLYING PISTON BENEFIT – https://flyingpistonbenefit.com/

ATOMIC BOB SHOP – https://www.facebook.com/groups/1324617964909190

The cousin for Harley-Davidson X440

By Wayfarer |

Even as X440 takes on the local behemoth Royal Enfield, the global two-wheeled giant Hero MotoCorp’s Mavrick 440 was unveiled in India at Hero World 2024.

Based on the Harley-Davidson X440, it features a power-roadster design philosophy and will be available for bookings in February 2024.

The Mavrick was co-developed in association with Harley-Davidson and is based on the X440. Available in five colour options, across variants, dealerships will accept bookings from February 2024 with deliveries beginning April 2024.

Harley-Davidson X440 and Mavrick 440 share the same engine and trellis frame. Yet it looks drastically different and may not appeal to those who loved the X440 design derived from Harley-Davidson XR1200.

Mavrick 440 will likely compete well against those left behind by the X440, including the big four Japanese brands. In all of this, the other retro-cruisers such as recently announced Honda CB350 and Jawa Forty-two and the Roadsters from Yezdi and TVS seem lost in the noise, with less brand appeal and even less after-sales expectations.

Find out the detailed specs, features and updates at

https://www.heromotocorp.com/en-in/motorcycles/Mavrick.html

With the launch of Mavrick 440, the buyers of Harley-Davidson X440 might also breathe a sigh of relief as the doubt for after-sales-service and parts might get resolved. Hopefully, H-D’s franchising strategy with Hero and Chinese QJ Motors (for China market) is a long-term strategy. I doubt if Harley-Davidson will again disappear overnight —since Hero has engaged so much resources, it is likely a tight, well-planned partnership.

* * * *

Annual Mecum Auction at Las Vegas 2024

By Wayfarer |

33rd Annual Vintage and Antique Motorcycle Auction by Mecum Auction at Las Vegas

January 24-27, 2024

ADDRESS

South Point Hotel & Casino

9777 Las Vegas Blvd S

Las Vegas, NV 89183

VIEW LOTS: https://www.mecum.com/auctions/las-vegas-motorcycles-2024/lots/

FOOD & BEVERAGE

The South Point Hotel & Casino offers a variety of favorites and local cuisine. Food and beverage stands are located throughout the facility.

Payment Options

Cash and credit or debit cards are accepted.

RV/CAMPINGRV/CAMPING

Camping on-site at the South Point Casino is not allowed. Campgrounds are available in the area and individuals are encouraged to check local listings for more information.

MOTORCYCLE SHIPPING

Whether you’re consigning your motorcycle or purchasing a new one, HaulBikes Motorcycle Transportation will deliver your bike safely to its new home! Contact HaulBikes at 888-HAULBIKES today. View rate information.

ROAD ART SHIPPING

Navis Pack & Ship

6185 S Valley View Blvd, Suite L

Las Vegas, NV 89118

lasvegas@gonavis.com or (702)494-9616

*All Road Art must be retrieved by 12:00 PM on Sunday, January 28. Any remaining items will be shipped via our preferred shipping company at the winning bidders expense.

ACCESSIBILITY

Scooter & Wheelchair Rental Information

Personal wheelchairs and mobility scooters are allowed. No on-site rental options are available.

Golf Carts

Personal golf carts are prohibited.

PETS

For the safety and comfort of both pets and people, the admittance of any and all animals is prohibited at every Mecum event, unless the pet is a service animal under the federal guidelines of the Americans with Disabilities Act or similar state or local laws.

LOST & FOUND

To report a lost item, please contact us at (262) 275-5050 or email info@mecum.com.

TV Schedule: Friday, Jan. 26 from noon to 5 p.m. (Live on MotorTrend+) and Saturday, Jan. 27 from noon to 5 p.m. (Live on MotorTrend+) (All times Pacific)

* * * *

Tell ’em Bikernet.com sent ya !

Colorado Motorcycle Expo 2024

By Wayfarer |

COLORADO MOTORCYCLE EXPO 2024

JANUARY 27, 2024 – 9:00am – 7:00pm

JANUARY 28, 2024 – 9:00am – 4:00pm

AT THE NATIONAL WESTERN COMPLEX IN DENVER

GET TICKETS https://www.coloradomotorcycleexpo.com/

Saturday Ticket = $25

Sunday Ticket = $20

Due to parking restrictions, we are unable to offer VIP tickets this year.

$2 discount for Military and 65+ (with proper ID at the door only)

Children 12 and under are free

A MOTORCYCLE EVENT YOU DON’T WANT TO MISS…

LARGEST INDOOR MOTORCYCLE SWAP MEET IN AMERICA!

The expansive venue, spanning 300,000 square feet, accommodates up to 800 vendor booths and swap meet tables. We welcome vendors of diverse varieties, ensuring you’ll find exactly what you’re looking for.

LARGEST MOTORCYCLE SHOW IN THE ROCKY MOUNTAIN REGION

Showcasing approximately 100 bikes vying for top honors in up to 20 categories, the Colorado Motorcycle Expo stands as the largest and premier motorcycle show in the Rocky Mountain region.

USED MOTORCYCLES FOR SALE IN THE CORRAL

Explore our selection of available used bikes for sale, or bring your own to sell. Join us for an incredible opportunity to present your bike to a vibrant audience of thousands!

LIVE MUSIC, ENTERTAINMENT, AND SO MUCH MORE

Experience the energy of live bands, captivating solo acts, engaging adult activities, a dedicated kid’s zone, and much more. There’s something for everyone!

* * * *

Tell ’em Bikernet.com sent ya !

Is Green the New Gray Area

By Bandit |

First and foremost, electric vehicles are expensive. Some studies suggest that people who can afford to buy all-electric cars represent a finite group, and that many of those consumers have already purchased an EV car or truck, meaning the available pool of buyers is shrinking. Also problematic is that due in large part to the high cost of battery replacement, there is a very small market for used electric vehicles. Basically, no one wants to buy them knowing that a big repair bill is headed their way. While battery technology will likely improve in coming years, as of today that technology and questions about the cost of building a sufficient charging infrastructure are major concerns for consumers.

Executive Director –

https://mrf.org/join