THE CHOPPER OF CHOPPERS FOR SALE, Part 2

By Bandit |

The master builders included Arlen and Cory Ness, Matt Hotch, Chica, Eddie Trotta, Hank Young, Kendall Johnson, Mitch Bergeron, Russell Mitchell and Joe Martin. Just up the dusty road roared the 2004 Laughlin River Run with all the temptations of Casino action including amazing food, entertainment, whiskey and girls. But the brothers stayed focused, almost.

Just 72 hours out they gathered at Dan Jackson’s Fort Mojave, Arizona, Desert Powder coat shop. Arlen Ness was assigned the shop foreman title, while Kendall Johnson, engine and trans builder. Mitch Bergeron handled frame and billet down tube construction. Russell Mitchell dialed in the handlebars and controls.

Matt Hotch hand built the fenders and the wild gusset under the frame neck. Cory Ness was responsible for paint and accessories procurement. Chica hand fabbed the gas tank, “but Johnny Chop helped,” said Hugh, and Eddie Trotta worked over the forks and front-end trees. Hank Young built the oil bag, Joe Martin the nasty pipes and pinstriping. And a late arrival Danny Gray supplied the hand made manta ray-covered custom seat—amazing.

The show had a design, but the King was only part of the scheme. “I wanted to depict the torment of the artists under extreme conditions.” Little did he know the bike would be turned over to him after he tortured the builders in the desert with hot iron pokers.

As the executive producer sat overlooking the mayhem of the final assembly while fanned by Vegas hookers and sipping long Island Iced teas he wondered if the concept would work.

“It didn’t at first,” Hugh said. “There was a lot of tension, people went off in different directions. All of a sudden, it just coalesced. You could feel the energy in the room. Everybody was suddenly working together, headed in the right direction. I think Arlen had a tremendous impact as the shop leader and guiding light in a dark tunnel of torment. It was touch and go for a while. If one of them had walked, they would have all walked, but they didn’t. The rebels held together.”

Funky Panhead Part 4, New Frontend Installed

By Bandit |

I spent a lot of money and time rebuilding an old 41mm wide glide for my 1969 Panhead build. It was one of those crazy builds, fulla twists and turns, but the glide haunted me.

It wasn’t long enough. I would have liked it to be 2-over for a better stance for a rider 6’5” tall. I squeaked another inch out of it with spacers over the springs. Of course, it rode like shit. I adjusted it, but it still rode badly. Maybe I’m getting old, but I don’t like that excuse. This bastard rode hard even with the wide, soft, cop solo seat.

Then the glide actually broke down. I lost the mechanical brake springs. They broke on the way to a Seal Beach car show. I limped home never daring to use the front brake for fear it would lock up and send me flying over the bars. I wanted to run a vintage mechanical brake set-up for the old look. In the past I was always able to make mechanical brakes work fine.

Finally, I started to notice how the lower aluminum leg jerked on the brake side. It needed new bushings. I reached out to Larry Settle, of Settle Motorcycle Repair in Harbor City. He knew of an old guy who rebuilt lower legs, but he might have retired. That was going to be my next move, tear the front end apart and ship it out, to have the lower legs rebuilt. Plus, they leaked. That also bothered me.

Then I got a call from the masterminds at Paughco. They recently developed a new springer configuration, because so many overseas manufactures stole their classic, flat side design. They came up with a solid, round-leg springer sort of in keeping with the early springers, before the VL or the big twin taper-leg springers. I love the Paughco taper-leg springers. They are classic. This one is distinctive in its simplicity.

There are several benefits of Pauchco’s 50-years of building springers. They are contained in the tree construction, the bends of the legs and the rockers. These front ends are meant to be ridden long and hard.

They also make a stock length front end and a 3-over, which I went for, when I made the deal to trade my glide for a new Early-styled round-leg Paughco springer. We made the clandestine swap at the recent David Mann Chopperfest, behind one of the old WWII buildings, so Dave Hansen wouldn’t see us and tax us for making deals without his approval.

I also attacked the rear of the bike with an old buddy seat, spring system to give the rear some suspension. It was a leap of faith that worked out like crazy, but I will get to that.

I requested the front end without chrome or powder, because of my patina effort. I painted the bare parts with a light coat of Rust-oleum primer and then a coat or two of Rust-oleum satin black. No matter how many times I’ve looked at that word in my long lifetime, I can never remember how to spell Rust-oleum.

Then I lashed the front end with some bicycle chain and smoothed and dinged the edges of the top triple tree. Paughco designed a new top tree to allow their risers, to be installed in the rear legs with1/2-fine thread studs or bolt common risers to the 3.5-inch center-to- center glide-like holes. I decided to go with the rear legs and cut the heads off ½-inch fine stainless bolts and made studs out of them.

I screwed 1-inch of the studs into the rear legs and had an inch for the Paughco classic brass risers. I used stud-green Loctite in the legs and ran a nut down to hold them firmly into place overnight. I removed the nut when I installed the brass risers.

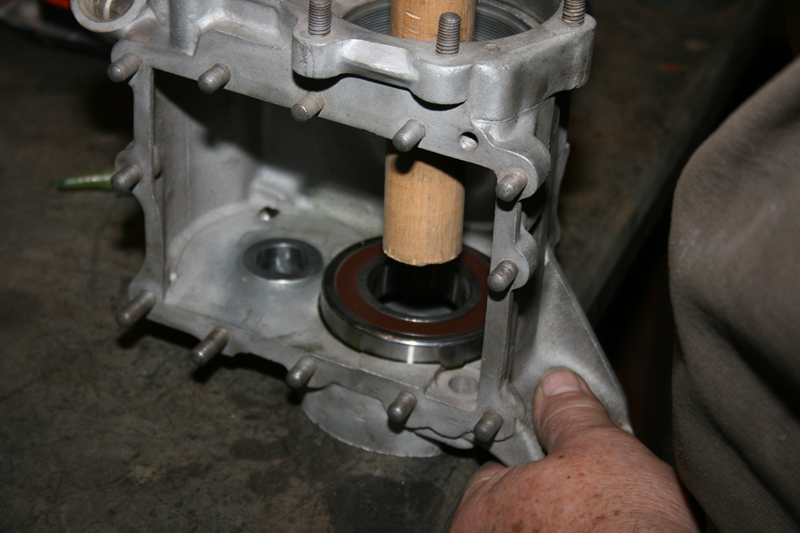

I installed the bottom bearing over the small dust shield against the bottom tree. I found a piece of thick 1/8-inch wall, 1.25 O.D. tubing and used it as a tool to drive the Timken bearing over the raised bearing surface on the solid neck stem. I also fed as much grease into the bearing as possible. For some odd reason, I had to clearance the dust shields to make them fit over the solid Paughco stem.

Back to the grease. I’m still using a large tin can of military bearing grease. I’ve had it since the ‘60s. About five years ago, someone gave me a new full can. I’ll bet I never get to it in my lifetime.

I was recently given some cool CMD Extreme Pressure lube tubes. We used it on Frankie’s FXR neck bearings, but in the heat, it started to drip and run down the leg of the front end, annoying. The old Navy bearing grease is the shit.

Okay, so I slipped the neck shaft with the lower greased bearing into place against the greased race in the neck cup and spun on the crown nut against the top bearing and upper dust shield, after it was clearance. Here’s another benefit of classic Paughco construction. A lot of frontend manufacturers dodge using a threaded nut between the top tree and the neck bearing.

It comes in so handy while installing a front end. It holds it in place to allow you to position the top tree comfortably. It also allows you to adjust the bearing tension. Then you can install the top tree and the top nut and tightened the hell out of it without messing with your bearing adjustment.

The Paughco front end comes with the rockers mounted and in place. No adjustment necessary. They are lubed and ready to rock.

I removed the solid brass, 4-inch Paughco dogbone risers from my old stainless-steel bars and was careful to install them on the stainless studs watching for the studs to turn or not. I tightened them down and adjusted the rubber mounted dogbone to align with the bars. Then I installed the bars once more.

I grabbed one of James old Dyna front wheels and used it to mockup the front end. Steve Massicote from Paughco recommended a left ‘88- ‘99 single-piston H-D Softail caliper on an 11.5-inch rotor with a 2-inch center hole to fit a pre-’99 Harley hub. He shipped a solid aluminum hub to Black Bike wheels.

Black Bike Wheels has helped me out a couple of times. I remember taking a dinged steel rim spoked, 21-inch wheel to them. The technician popped the unit in a vice, smacked it with a soft hammer and it was golden. They also built the 23-inch wheels on my flat-sided tank, factory racer. Amazing wheels.

They expanded and moved to Van Nuys, California. They now manufacture any-sized spoked wheels for any make or model motorcycle. They build their own hubs, rims, and spokes. They can lace and true anything and powder, polish or chrome any of their products.

In this case, we are going with a used, dull, aluminum, 19-inch rim and unpolished stainless rim, for the patina look. So, there’s some old and some new to this beast. I will add an old pre-’99 factory rotor to a Paughco aluminum hub, which we might black out, or Paughco was going to send me a hub cap, I could flat black and add a little rust.

We’re getting close, but I had to take it out on the road and see how it handled with the sprung seat. I took the seat bar out, because it was going to smack the fender. I added a straight piece of steel to the center and it gave me an additional 2 inches of travel. I’m still going to do something to protect the fender.

Okay, so this puppy hasn’t run in a couple of months but fired right to life. I maneuvered around the shop and into the street for a test run. What an amazing difference. The turning radius was way better and it blasted around the rough streets without an issue. What an amazing difference in ride and handling.

Don’t get me wrong. You can’t beat a glide for top end runs and the twisties, but for a classic cruiser, this puppy now hit the spot.

Hang on for the wheel and disc brake install.

–Bandit

Funky Panhead Sources:

S&S

Biker’s Choice

STD

www.STD.com

JIMS Machine

Lowbrow

Mallory

www.mallory.com

Accurate Engineering

www.accuratengineering.com

Bennett’s Performance

Paughco

Departure Bike Works

www.departurebikeworks.com

Spectro Oils

Chopper Dave

www.chopperdave.com

Black Bike Wheels

www.blackbikewheels.com

FUNKY PANHEAD PROJECT, Part 1

By Bandit |

My grandson wrecked his Dyna. He thinks he went down on a slippery west side boulevard, but the bike looks like he was rear-ended, which launched his girlfriend. She was seriously damaged, but survived. He got scuffed and walked away.

He needed a place and some guidance with his ’05 Dyna. He could have sold it and moved on, but he was so impressed with the performance after Bennett’s Performance tuned it and added some S&S TC cams, he didn’t want to let it go.

Anyway, we rambled throughout the packed isles looking for parts and I came across a large flatbed truck and a line of new, bare rigid frames displayed in front. Great looking frames and I inquired. Kraft Tech only sells to distributors like Biker’s Choice, but they bring a few frames to the swap meet once in a while and the price was right. In fact the owner’s son, Chris, was on hand and he recognized me and offered me a better deal.

The frames were obviously set up for Evo engines and 5-speed transmissions, but looked almost stock. I couldn’t resist. We carried that frame up and down isles until we finally headed toward the exit with no Dyna parts, but the frame and a set of stock Softail tanks, which the frame was set up for.

As I meandered toward the exit, my cell phone rang. It was Brad Olsen, an old friend who recently scored an Oregon shop’s inventory and stashed it in a warehouse near a river leading to the sea. “Yo,” Brad said. “I need to recoup some of my investment. Do you need a Panhead engine?”

I about shit my pants. I had just scored a sharp rigid frame, a set of fatbobs, and I knew I had a 5-speed Softail transmission at the Bikernet Headquarters. What the fuck? Hell yes, I needed a Panhead engine!

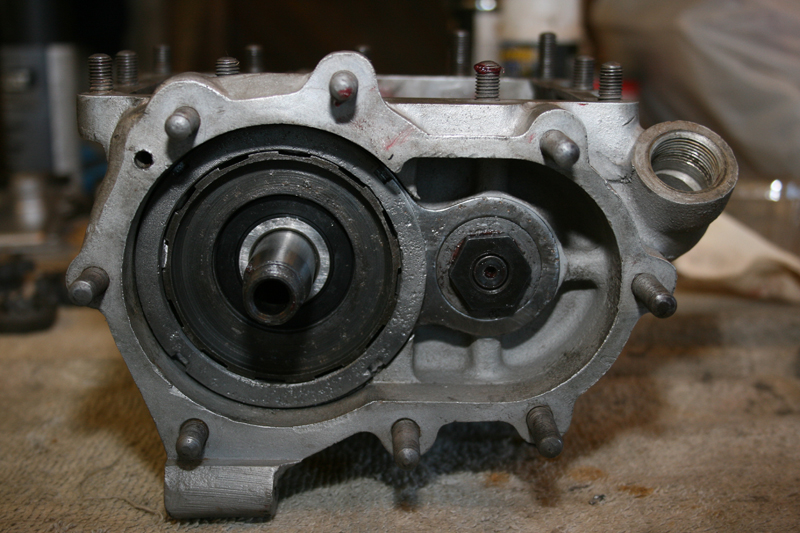

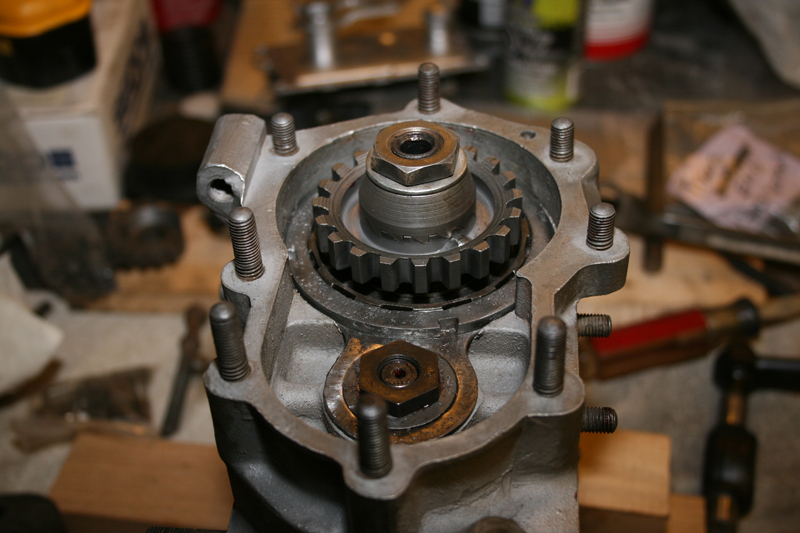

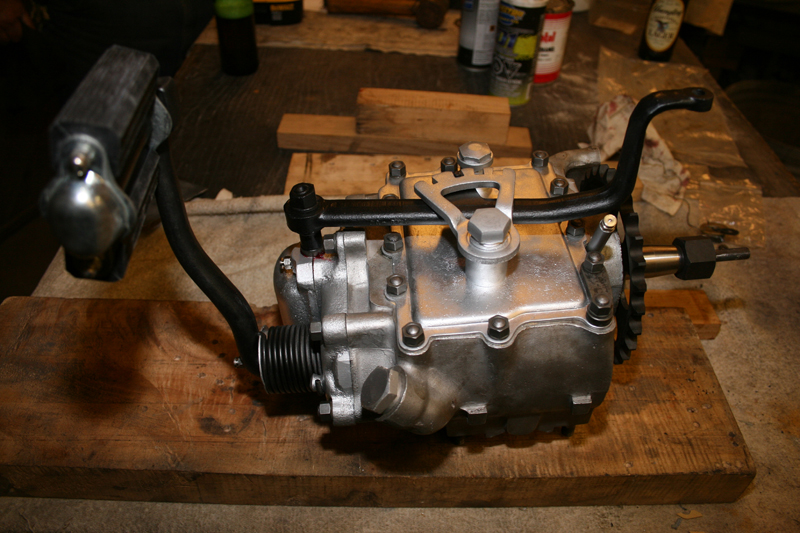

As it turned out, the engine was seriously incomplete, but with a good twist. The ’69, last kidney, Shovelhead right case was mated to a ’79 left case, which would allow me to run an alternator and Evo (Baker tins) primaries. I hauled ass home from the swap and started to dig through drawers, cabinets, and lockers looking for parts.

I created a pile next to my lathe, but when I stood up, I wondered what the hell I needed another motorcycle for. That wasn’t the mystic point at all. Fuck it, I was inspired and on a roll.

Here’s a code that works for us bikers. I tell young guys all the time to start to create equity in your lives for your future. You can buy and turn houses. You can restore a car, write a book (not a good idea), paint a painting, etc. But if you’re a biker, building bikes is perfect. No, they are not always worth a bundle, but they are like putting money in the bank. Think about that the next time the ol’ lady bitches at you for building another motorcycle. How’s she doing to build equity for your future?

Even before the swap meet kicked me into gear, I was moved by Go and Tasumi at Brat Style in Long Beach. Michael Lichter introduced me to them, just down the street on the evil industrial west side of Long Beach. They build the coolest shit on the planet with a major twist. Everything is vintage, seriously vintage. Go can build a totally custom tank and install it on a ’39 Indian Scout frame, but by the time he’s done, you would bet that’s stock part and 70 years old.

What completes his bike building twist? It was his amazing painter, Deny 528. Maybe I should keep this a secret. But fuck it, it will slip out anyway. I hope to feature one of Deny’s bikes this week, a restored (don’t forget that word) 1946 Indian Chief.

I was gone. I couldn’t think of anything else but this Panhead project. I dug around and Mike from Pacific Coast Cycles came up with an oil tank. He’s a major fan of Kraft Tech frames. “Everything just slips together,” Mike said. And he’s also a major fan of Paughco springers. He has about a dozen rollers in his one-man shop. If you’re after a cool project, give him a call.

Daily, I made lists of needed parts and started to make calls. I couldn’t stop and then my grandson flew to Deadwood to be apart of Scott Jacob’s Artist Retreat. Suddenly he wanted to go to Sturgis. I came up with a plan. I rode to Sturgis and back last year, so this year, we could alternate the plan. How about taking two old bobbers to Sturgis for the kicks?

We could stuff them into the back of a van and cut a dusty trail, but they would need to be short and tight. We would take the Panhead and a Shovelhead I’ve had for years, built by the guys at Strokers Dallas under the boss, Rick Fairless. We were about to chop the Shovelhead some with a Paughco scalloped gas tank, bars, solid brass risers, and a Softail oil bag. That would do the trick.

The Sturgis 2017 plan boiled in our minds. Suddenly, I had a deadline. Oh, what the fuck? I was inspired by many factors, but I still needed a few pieces to make it happen.

The engine was missing a cam and most of the cam case elements. It needed a carb, intake, distributor, oil pump and I started digging around. I had a set of rebuilt Panheads, but they were early model and this puppy would need outside oilers. I started to ask around. I also needed the right year cam cover and I found one on line.

Berry Wardlaw from Accurate Engineering offered to help when I couldn’t find any through STD. Billy McCahill was having issues with his foundry and didn’t have castings. Berry checked with a couple of distributors and no one had any in stock.

Berry searched forums and then found a set on Ebay. I immediately ordered them from Wilson Cycles, Inc. in Roswell, GA, but when they arrived, I encountered a problem. One was perfect with valves, an O-ring intake manifold flange and the outside oiler boss. Unfortunately the other didn’t have an outside oiler fitting. It was an early model.

All right, we will deal with that problem, with Dr. Feng, our officially certified aluminum TIG welder. As it turned out, working with Ebay, I received a call from Billy McCahill, of STD and RSR, or Ryde Shop Racing. He’s like a mad scientist, but he said they made a mistake two years ago and shipped out this order to a shop in Georgia. They never heard a word until I surfaced. I hauled the internal oiler head to their Downey shop and they replaced it. I was there for 30 minutes and heard 30 industry stories, some of which I will share in the news. Amazing!

We hit the swap meet again and found a cop solo seat from a major seat guy, but he had a pristine stock seat. I had an old hinged fender from an early swingarm Pan. I knocked out the pin and installed the bobbed fender with the help of Lowbrow’s new universal fender brackets.

It’s strong as a bull and fit like a champ. My funky MIG weld didn’t hold a candle to the precision Kraft Tech TIG welds on the frame. Sorta embarrassing…

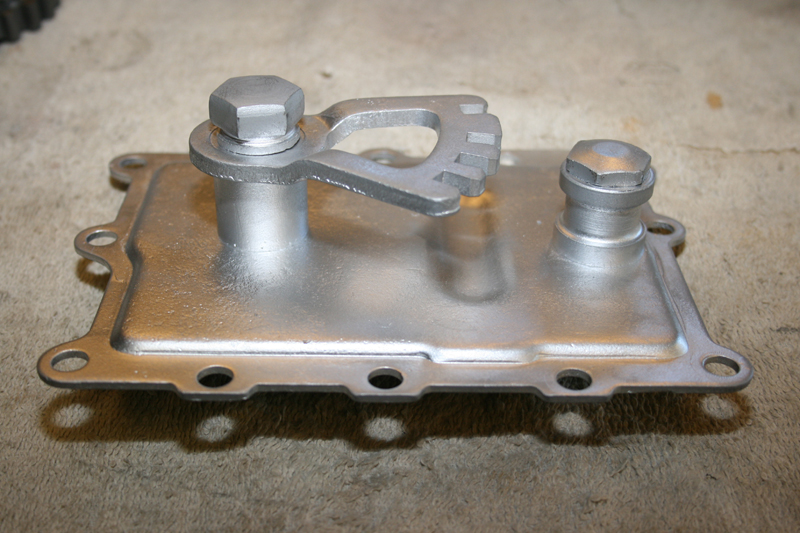

I dug out a Softail 5-speed transmission, but I’m trying to figure out the plate to mount it—I did today. I called Chris at Kraft Tech and quizzed him. I have a Paughco offset 5-speed plate but need a stock ’86-’99 Softail tranny plate for a 5-speed. There are so many configurations and Paughco has them all.

I want to write a tech about ordering frames and all the configurations available. It’s not just about rake and trail anymore or wide tires, but left and right side drives, which transmission, which set of gas tanks and the type of seat being used. The list goes on. Hopefully, if the Paughco crew can help out, and with Biker’s Choice, we can make it happen.

I found a wide glide front end at the swap meet, Ultimately, I wasn’t happy with it, but we made it work, (I hope) with an old drum front brake. I found some neck bearings and replaced the junk one. I tore the whole front end apart and cleaned it. The Paughco axle did the trick to allow it to be installed. A local shop laced the star hub to an old 18-inch used aluminum rim.

I spoke to the guys at Spectro about which fork oil to run in the legs. Joe Russo recommended Fork Oil Type E. 20 SAE, since it’s a one-up light bobber. “Heavy two-up bikes would use the 40SAE,” said Joe.

The brothers at Paughco are the best and have the best. After digging through my shit, I needed just a handful of vintage parts and pieces from the Paughco factory, like the correct front axle for an early glide. I made the mount for an old spotlight out of a bracket I built for a Bonneville bike but never used.

I needed the right side rear brake lever, plate, return spring and plunger, but I had three Wagner master cylinders. This Kraft Tech frame was set up for a Softail style disc brake. Years ago, we installed PM brakes on Dale Gorman’s Softail and I ended up with his stock solid aluminum rear wheel and brakes. They would do the trick.

I had most of the pieces for the left side, except for one, and Paughco had it, the shift linkage arm. And I didn’t plan to run a dash, but I needed something for electrics, a switch, whatever. I ordered a Paughco universal tin toolbox and then discovered something wild at an antique store, a K-model motorcycle trophy and it’s a heavy casting.

The notion is to build a simple, easy to handle bobbed Panhead. But for some odd reason, finding an early automatic-advance distributor is not easy. I don’t want any extra bells and whistles on this bike, no advance and retard mechanism, jockey shift, etc. Then I found a Mallory electronic ignition system in a locker from our ’06 Bonneville effort. I spoke to Berry Wardlaw from Accurate Engineering and it will do the trick. I’m rocking.

I went through the front end from stem to stern, installed new bearings, cleaned it, drilled lightening holes in the brake backing plate, and found a set of stock configuration stainless bars and some goofy 4-inch aluminum risers using a stock cap. I’m still working on the cable, lever and cable adjuster. I called Barnett’s today.

The bike is already headed back together for Sturgis. If the paint and engine comes together I should be cool for the run. Hang on for the next report.

Sources:

Paughco

Pacific Coast Cycles, Long Beach

Barnett’s

Kraft Tech

Spectro

Baker Drivetrain

www.bakerdrivetrain.com

S&S

LowBrow

Bikernet Bike Build: BETSY’S REVIVAL STORY Part 2

By Bandit |

Ahuge expression of gratitude goes out to my friend Steve Brownell forselflessly donating his time and materials to bring this GypsyMachine back from the dead. As a fellow biker himself Stevereiterated to me a manta I hear and have used time and again, “That’swhat we do, brother.” With a new lease on life I closedthe tailgate behind the NEW girl, gave Steve a big appreciative hug,then drove off waving as I watched Steve and the crew in the rearview sending us on our way to future adventures yet to come.

Rebirth of an American Classic: The Build Begins

By Bandit |

|

|

|||

|

|

|||

|

|

|||

|

|

The Amazing SHRUNKEN FXR Updated

By Bandit |

Once upon a time there was a bike built called the Shrunken FXR. Keith “Bandit” Ball, of Bikernet and other assorted fame, built it. By a stroke of good fortune the bike became mine through the generosity and trust of Keith Ball.

This bike was my daily commuter for a handful of years. It was and is always a challenge and a ton of fun navigating the streets and freeways of Los Angeles on two wheels and especially on a custom built motorcycle.

I decided it was time to update the look of the bike as well as do some fine-tuning of a few mechanical items I wanted to switch up a bit. Below is a brief summary of what was done, again primarily with the help of friends and some extra cash from my Pops to help get it all finished up proper.

First I replaced the front fork tubes with new fork tubes made by Forking by Frank. Styles have changes, so I installed new handlebars, 10-inch baby apes mated to Black Boyd Motor Co. risers.

I work at the magnificent ARCH motorcycle company and LA Chop Rods, so natch; I installed Black Anodized hand controls by ISR purchased. They are absolutely the best and contain the mechanical Bandit approved styling.

I replaced the mirrors with 2-inch Blind spot jobs by CRG (Small and work great). We

Powder-coated the classic Performance machine wheels black (Thanks to Custom Metal Finishing in Gardena CA, who handle the high-end ARCH motorcycle extreme perfectionist coating).

We manufactured a new Shift arm and Brake arm to improve function. Ryan Boyd, Boyd Motor Co./Arch Motorcycle, is a master machinist and engineer. He configured then machined these components to enhance the rear brake functions, and it now works like a charm, plus it improved shifting dramatically.

We replaced the pegs with something sport bike like and again Ryan stepped up to design and machine one-off mounting bracket adaptors.

We reworked the exhaust basically back to the original first version, added BBQ paint and LA County Chop Rods baffles.

These upgrades, in addition to the rear shocks by Progressive and my comfy Saddlemen seat make the Shrunken FXR road ready and looking fresh for 2016.

Me owning this bike and updating would not be possible without the help and kindness of the following wonderful humans beings: Keith “Bandit” Ball, Dr. Ladd Terry, Gard Hollinger, Ryan Boyd, Jose Laguna, Saddlemen, L.A. County Chop rods, Custom Metal Finishing, Boyd Motor Co., Frank’s maintenance and engineering.

Here’s a link to the original feature, if you search the Shrunken FXR on Bikernet, you’ll find all the build articles: http://www.bikernet.com/pages/Amazing_Shrunken_FXRThe_Full_Feature.aspx

–Buster Cates

The Magnificent ARCH motorcycle factory

LA Chop Rods

Saddlemen

BDL

Progressive Suspension

The Mudflap Girl FXR Saga

By Bandit |

It all started when a brother was desperate for cash and I bought a basket case Dyna, and with the help of JIMS machine turned it into an FXR. I started to build it for my son, Frank, the tattoo artist, around an old Kenny Boyce-styled pro street frame. Making progress on this build, with a massive upside down Custom Chrome front end, a brother stumbled into my shop and told me about Paul Cavallo and Spitfire Motorcycles.

Paul’s been around the industry for a couple of decades. When the economy tanked, he hung on with his dad and started Spitfire motorcycles. He was struggling and a brother thought I could help by using a couple of his Spitfire components on a Bikernet.com build. I went to visit Paul and was inspired by his non-stop drive to create new components daily, build world-class old school chops for customers, and kick ass at shows all over the country.

Then I was hit with the bike builder blues. My girlfriend left and I was forced to sell my 2003 Road King, leaving me with a ratty rigid Shovelhead and a Bonneville racer to ride. I needed a new girl and a long distance rider. Too often, around the campfire we debated twin cams versus Evos and most of the bros confirmed the solid stature of the FXR configuration. A plan formulated to build myself another FXR. I returned to Paul’s shop to cut a deal on a chassis for myself. Both were stretched, almost single-loop, long-distance riders with Spitfire Girder front ends.

Paul’s team built my chassis in pure traditional FXR style and Frank’s in the pro street configuration. We re-manned Frank’s FXR engine in black and chrome, and I ordered a bone-stock crate H-D 80-inch Evo. Both transmissions were rebuilt by the JIMS crew to be 6-speed overdrive units. I went with chain final drive and Frank used a stock belt.

The overwhelming concept revolved around building a bike that’s a chopper to the bone, but could be easily ridden across the country. My stretched gas tank holds well over three gallons, the oil tank contains nearly four quarts of oil, and I installed an oil cooler for heat waves. The Spitfire bars are held in place with Custom Cycle Engineering dog bone rubber-mounted classics.

I used Contrast Cut Performance Machine grips and pegs for style, yet road comfort. The bike is rubber-mounted for vibration-free riding. I worked closely with David Zemla of Progressive suspension until we configured a shock system capable of affording me some suspension with somewhat limited travel.

The girder is an uplifting quandary. With the Spitfire structure I could feasibly install almost any shock system, with whatever spring rate I decided on. I’m still messing with the gas-operated Rockshox.

I’m missing the best part, the Saddlemen seat. This seat was carefully configured at the Saddlemen manufacturing facility in Los Angeles, from the heavy-duty fiberglass seat pan to the spine-relieving slot, to the better than foam gel, and the ultimate breathing resilient fabric. That puppy is amazing.

The engine is virtually stock with the exception of a Bennett’s Performance-installed Andrews Cam, S&S oil breather gear, and Branch flowed heads, all their state-of-the-art valves and springs, and intake manifold. I ran an Andrews EV-27 cam and Andrews chrome-moly adjustable pushrods for less flex, a new cam bearing and the Branch flowed stock heads, for 8.9:1 compression, 78 cc Branch-flowed chambers, and 75-80 horses at 2,600 rpms.

The bike was built specifically for the road, but with chopper styling. I can’t leave anything alone, or ride a stock bike. It’s against my nature, but I can ride a scooter that will get me there comfortably in style.

For the first time in my bike-building life, I built this bike in bare form, wired it, and rode it for almost eight months. The benefits are immense, since I could make changes and adjustments throughout this road or rode research period. It gave me an extended period to investigate color schemes, build the front fender, break stuff, repair, and outright replace components, including my goofy chain guard.

It’s odd, but even with 2,000 miles under her belt, I still came up with last-minute changes during the paint and powder process. I added a keyless ignition system from Digital Dawg, which proved to be a safety and security feature. The drawback to riding a bare vehicle for an extended period included rust and oil management.

Still, when I assembled the bike for the final time, I ran into rear powder-coated fender expansion, and adjustments to the position of my one-off Spitfire oil bag to prevent chain damage. Maybe a rear belt would have been a wiser decision, maybe not.

Finally, the Mudflap Girl represents the open road. She represents the drawbacks of industry when it takes our girls away from us. And lastly she represents the desire to find our Mudflap Girl at home or down the road.

Name: Keith “Bandit” Ball

Owner: Lt. Ball

Builder: Ballintsky

Year, Make & Model: 2012 Mudflap Girl FXR

Assembly/Builder: Ballorama

Timeline: 8 months

Year/Model: 2012 Girder

Builder: Paul Cavallo, Spitfire Motorcycles

Type: Girder

Triple trees: Spitfire

Extension: 9 inches over stock

Year/Model: 2011 H-D

Rebuilder: New

Displacement: 80 cubic inches

Lower End: assembled by S&S

Balancing: S&S

Pistons: H-D

Cases: factory

Heads: Branch O’Keefe

Cams: Andrews

Lifters: S&S

EFI/ Carb: Trock modified CV

Air Cleaner: Roger Goldammer

Pipes: D&D

Ignition: Crane Hi-4

Year/Modifications: 2012 JIMS overdrive 6-speed

Engine sprocket: BDL

Trans sprocket: JIMS 23-tooth

Wheel sprocket: 51-tooth

Secondary drive: Biker’s Choice chain

Year: 2012

Designer/Builder: Paul Cavallo/Spitfire Motorcycles

Rake/Stretch: 5 inches up, 2 out

Bars: Spitfire

Risers: Custom Cycle Engineering dog bones

Fenders: Bar Knuckle/Toby/Bandit front, Biker’s Choice rear

Gas Tank: Biker’s Choice

Oil Tank: Spitfire

Headlight: Old spot

Taillight: Donkey from Biker’s Choice

Speedo: Wire Plus

Pegs: Performance Machine Contrast Cut

Electrics: Wire Plus, Digital Dawg (keyless), Biker’s Choice

Seat: Custom by Saddlemen

Front Wheel: Metalsport

Front Tire: Avon

Size: 19

Rear Wheel: Metalsport

Rear Tire: Avon

Size:

Hubs: Metalsport

Rotors: Metalsport

Brakes: GMA

PAINT

Bodywork/Molding: none

Painter: Chris Morrison and George the Wild Brush

Color: Super silver

Powdercoating: Worco silver and asphalt satin black

Biker’s Choice

BDL

Custom Cycle Engineering

D&D Exhaust

JIMS

MetalSport

S&S

Saddlemen

Spitfire

Wire Plus

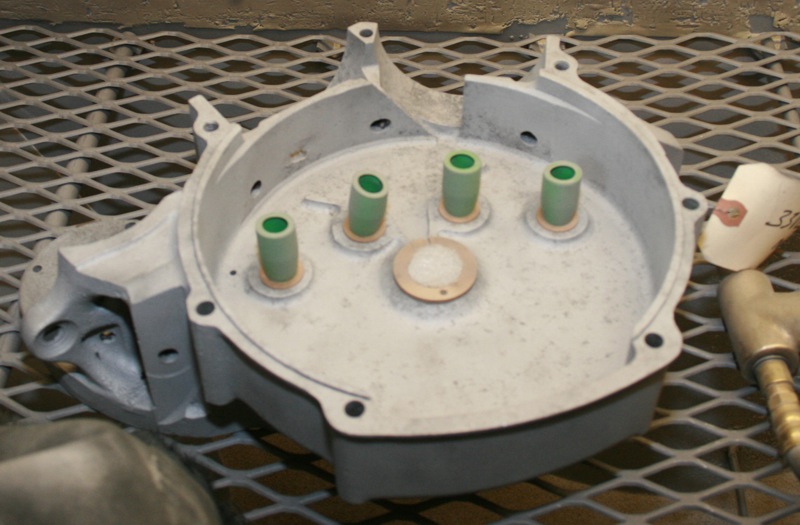

Rebirth of an American Classic: Case Repairs

By Bandit |

|

|

|||

|

|

|||

|

|

|||

|

|

|

Biker’s Choice TWIN-POWER Ignition Tech

By Bandit |

I recently rambled about never giving up. This tech is an example in not giving up, and looking for opportunities for success. James Simonelli recently went to work for Biker’s Choice and it’s a company constantly looking for opportunities to succeed. They continue to expand and James is working hard on the Twin Power line of products.

I built this bike a few years ago and enjoyed each element of the build. It was my first opportunity to work with Black Bike Wheels and installed the new 23s at the time. I also worked with Rick Krost and the Paughco team, who were building his US Choppers frames and several components. I also worked with Chica for the first time to build my rear fender. This bike slipped together like a dream.

I was digging the old board track notion from the ‘20s, although I wasn’t the first. Arlen Ness built vintage-styled bikes with sidecars around Sportster drivetrains. The master, Don Hotop build a Silent Gray Fellow more refined than any the Davidson and Harley team built — it was beautiful. The Shadley brothers built another example with a sidecar, which I proudly featured recently.

I was just one in a long line of masterful Hamster builders to take on the challenge. When the bike was completed and I slipped the key into Phil’s Speed Shop ignition box and fired it to life, it purred like a kitten. It was a beautiful thing and I appreciated all the help and guidance slipped my way to see this project through to fruition, including the hand-tooled seat by Glen Priddle in Australia. Some of my welds were not handsome, but I was proud to see this puppy finished, and then I went for a ride.

My first challenge was the handling and the two, seemingly giant Black Bike spoked 23-inch wheels and Avon Tyres. It felt odd, but then it popped and coughed at just about 30 mph and I thought it had to be jetting. I carefully tuned and ran an S&S super E for the classic styling and shorter reach sticking out the left side of the bike.

That’s one of the distinct reasons for a Crazy Horse, now American V-Plus engine. It fit in the realm of making a bike look truly old, especially with the carb leaning out between the cylinders on the left, like old flatheads. No matter how I jetted it, it wouldn’t run past 30 mph. Ultimately, I changed the carb for a Mikuni, and I switched out the original Crazy Horse Ignition for a reliable Compu-Fire. I switched coils. I changed the exhaust by removing the muffler. Nothing changed how it ran, and I moved on to the next project.

But obviously it bugged me and recently, when James pointed out the new Twin Power ignition product from Biker’s Choice and suggested an install, I jumped at one more chance to make this beauty come to life. James suggested I install it with Primo-Rivera advance weights, although Twin Power sells a kit.

“Try it in the dual fire mode,” James suggested. “You’ll like the exhaust note and the old school thumping idle.”

Back to the initial problem, I heard strange rumors regarding Crazy Horse engines, and struggles to make them run. John White bought a bunch of the Bottlecap engines when the Indian effort failed in Morgan Hill, California. With the engines in hand, he started Crazy Horse Engines. He was a big construction guy and hoped to build something from the stylized engines, and I agreed with his philosophy. The engines were magnificent, classic, 100-inch, and different.

The company is now American V-Plus and Irma Martin, out of Auburn, Washington, owns it. She is working with Frank Aliano to reintroduce these puppies to the aftermarket and custom world.

As a rider, Frank spent over ten years racing motorcycles in all types of environments, including motorcross, cross-country, scrambles, enduro, hill climb, TT, flat track, ice, and drag racing. As a builder, Frank’s custom and high power creations continue to be trophy winners around the country, with several featured in national magazines.

As a designer, Frank spent decades in engineering, fabrication, machining and product development for Indian Motorcycles, American Quantum Cycles, Big Dog Motorcycles, A&A Performance, Double Services, and more.

Frank designed the billet system to plug more tuneable and flexible Evo ignition systems onto a Crazy Horse and now V-Plus engine. I reached out to Frank, because my investigation steered me to Micah McCloskey and then to Keith Ruxton, who designed the Worlds Fastest motorcycle engines in 1990, two Shovelheads built by Micah. They took the Easyriders streamliner to 321 mph and the record for 16 years. I was a member of the team.

Keith suggested, since I have switched out the carb and ignition, that the breather gear was out of time. “It could be flooding the engine with oil and causing it to fail,” Keith said. And so I dug in during the process of switching out the ignition system to Biker’s Choice Twin Power.

The Twin Power electronic ignition from Biker’s Choice fits ‘70 – ‘99 Big Twin models and ‘71 – ‘03. The unit is entirely self-contained and fits under the original points cover. It can be wired single- or dual-fire, and the built-in timing light allows for easy timing.

Front to rear timing is accurate to 1-2 degrees. It is delivered with a one-year manufacturer’s limited warranty, and they are made in the USA.

Twin Power coils are high-quality direct fit with at least 20% more voltage than stock.

These coils improve starting, stop high-speed misfires, and increase mileage and overall performance.

They are available in black or chrome and carry a one-year manufacturer’s warranty.

I went to work digging into the cam cover of the V-Plus 100-inch engine. I removed the point cover, hand-engraved by Heather New in Canada, with the 5-Ball Racing mascot, and then I removed the Compu-Fire ignition system, the ignition cap and the first level of cam cover. Frank coached me on removing the final billet aluminum cover.

“You may not need to back off the pushrods,” Frank said, but I ended up backing them off for a couple of reasons, including ease of replacing the cap. It can be a bastard if you don’t.

“This plate has a gasket and is held in place with steel dowel pins,” Frank said and he was right. “Take a claw hammer and install a quarter/20 bolt with a couple of washers into the plate. Use the threaded hole closest to the cam. With the claw hammer, leverage against the cam and hook the bolt.”

I readjusted the valves and looked for top dead center on the front cylinder with a massive tie-wrap. The tie-wrap cannot damage the sparkplug threads or any internal parts. Dominick, another master builder here in LA, suggested the tie-wrap.

“Once you have it at TDC, back it down 7/16-inch for about 30 degrees before top dead center, and your timing mark should show in the timing hole,” Dominick said. He was dead right. Worked like a champ. I grabbed a silver felt pen and was able to make marks to indicate TDC and 7/16-inch down. The timing mark popped right into the hole and I centered it by jacking up the bike and using the massive Black Bike wheel to move the engine in 4th gear.

Here are the Twin Power T/R #21-6500 ignition guidelines. They wanted me to rotate the motor until the front cylinder showed the fully advanced mark in the center of the timing hole, during the front cylinder compression stroke. Note: The compression stroke is evident when the both front valves are closed and you can rotate the pushrods with your fingers.

I installed the new ignition, keeping the rotor index hole in line with the light on the ignition, basically at 9:00. This system automatically runs in the single- or dual-fire mode, depending on how you wire the coil or coils. If it’s not in the 9:00 position, you’re on the wrong compression stroke. Rotate the engine again.

James recommended the dual-fire mode so I wired the Twin Power mini coil with the red wire heading to one lead and the black and white wires going to the other lead (it doesn’t matter which lead you chose on these coils). For single-fire coils, you need to run your hot wire and the red wire from the ignition system to the positive side of the coil, the white wire to one coil and finally, the black wire to the other coil.

This mini coil will afford more cooling space around it while it’s stashed between the heads. This coil doesn’t indicate a positive or negative lead position.

I ran the gray tube insulated wires out of the bottom of the cone cover and basically around the engine and up to the coil between the heads where many coils are located. I wish the insulation was black, and in hindsight I would have run shrink tubing over the gray sleeve for additional protection. I ended up extending the wires about a foot.

I also soldered a length of 14- or 16-gauge wire to pull the new wires through my existing loom. It worked like a champ to hide the new wires. I extended the wires, soldered them in place, using the Frank Kaisler soldering tool and his system for connecting wires, which can be a pain in the ass. He basically cuts and strips his wires and feeds one into the other for a direct connection, which also does not cause a lump in the wiring. It’s almost like shoving a key into a lock and it sometimes takes some maneuvering. That’s where his handy-dandy tool comes in.

Don’t forget to install the hot wire from your ignition switch to the hot side of the coil. You will need that power. I installed a new Twin Power Lithium Ion Battery while I was at it. What an amazing puppy.

This battery fit like it was meant to be. Most of these Twin Power Lithium Ion batteries were designed for stock applications, but we found just the right one for my situation.

Note: Use this ignition system with 3 to 5-Ohm coils.

After the coil was wired and actually before I completely installed the Twin Power ignition system, I installed the magnificent Rivera/Primo mechanical advance weights. I lubed the weight axles with some engine oil and slipped them into place over the cam and then slipped the billet aluminum rotor in place with timing magnets embedded into the cylinder. Be careful, the rotor only fits over the stem in one way. Note the position of the flat.

I repositioned the ignition plate and turned on the ignition switch. The red LED light lit up, and with a right angle punch I was able to push the rotor into the advanced position. It only moved about 20 degrees, if that. The light came on, indicating power to the coil and the ignition system. The key is to rotate the rotor counter-clockwise to the fully advanced position and have the light go out. As soon as you release the rotor, the light should come back on.

I always shoot for the exact link. I want it to light up at the exact point that the rotor moves. The coil and the spark plug fires the moment the LED light shuts off.

The timing procedure is exactly the same for both single- and dual-fire operations. The front and rear cylinders are internally timed and accurate to 1 degree.

That’s when life got interesting. The Redhead loaded up my 5-gallon gas can with premium and I poured a couple of cups in the tank and turned on the petcock. Nothing. I monkeyed with the carb. Nothing. Sometimes there can be a vacuum. I almost filled the tanks; still, nothing passed through the clear glass filter. I started at the carb and removed the line. Still nothing. I removed the line to the brass, inline petcock. No joy.

I could even looked down the mouth of the petcock and saw the large ball valve. I could see it turn and open. Nothing. If it had worked, my face would have been covered in gas. Then I attempted to remove the petcock.

I moved a large crescent wrench into position to back up turning the brass petcock and was immediately sprayed with gas. It was one of those strange moments in the life of a mechanic. Sure, it was a pain in the ass, but it always seems that stuff shows up at just the right time. The trick was to get all the fuel out of the tank so I could replace the split line, plus the petcock was clogged.

With the Redhead wearing protective purple gloves, we maneuvered large old fuel lines, funnels and the gas can to carefully remove all the fuel. I replace the split line (I have never, ever seen a line split like that). We removed the petcock and discovered what appeared to be a glazed layer above the ball valve. The redhead cleared it out with a short piece of brass rod and the fuel delivery system was replaced and fuel added. The 5-Ball factory racer fired right to life.

I spoke to Keith Ruxton the day before, and he told me that top end breathing engines, especially high performance engines don’t need breather valves, or even reed valves. I started looking at fuel delivery from the gas tank, which makes a lot of sense. I need to check to see that my fuel line will deliver 16 ounces of fuel in one minute, according to Dr. Ruxton. I removed the fuel line from the carb, stuck it in a measuring cup, checked my watch and turned on the petcock. It filled it to the 16-ounce mark in about 20 seconds. It wasn’t fuel delivery. So, I’m still not sure if my sputtering problem is solved.

I noticed one more item that needed to be addressed. When tightening the advance bolt, the rotator rubbed against the ignition plate, which would mess with the advance weight mechanism. First I took out the plate, because this cone was removable and if the Allens were loose it shifted around. I loosened them, shifted the system and retightened them. It was substantially better, but not perfect. This wouldn’t happen with a stock cone motor.

“The weights and the rotor have to be completely free to be able to advance,” said Ben Kudon, the Executive Director of Rivera-Primo

I reached out to James. “Here’s what you can do to Auto Advance units. Put a drop of blue Loctite on the advancer bolt and do not over-tighten. Spin the motor without the ignition in place and watch the rotation. If it is eccentric, take a small punch and give a tap on the flat of the hex head screw that will shift it to best center it, until it runs true. Please let me know, nothing should need to be modified. Occasionally, a shim is needed between the advance unit and the cam to shift the mechanism outward.”

“I am not familiar with the Indian cam cover, might be a little different from H-D. Does the plate fit nicely and rotate easily in the recess or is it tight? If this is tight, you may have to slightly sand or file the plate O.D.” That’s what I did until the rotor was centered. I also noticed the hex rubbing on the gasket. Again, this wouldn’t happen in stock applications. I cut a hole in the gasket and rotated the gasket to allow the 5-Ball Racing cap to set out slightly more. Done deal. James also suggest thin washers under the stand-outs, which would accomplish the same thing.

I took the bike for a ride. Over and over it fired right to life and hummed, but again is sputtered. I called Phil at Phil’s Speed shop late at night. He was still working. “It could be the cam timing,” said Phil. “They may have switched the gear for a better pinion shaft mesh and since there is no direct key-way to align the cam, it could have shifted.”

I’ll pull the cam today and take it to Bennitt’s Performance or Branch Flowmetrics to have it checked. Never give up!

Biker’s Choice

Paughco

Rivera/Primo

Black Bike Wheels

Chica

US Choppers

Rick@USChoppers.com

Phil’s Speed Shop

941 West Collins, Orange CA 92867

Appointment (714) 771-6727

Avon Tyres

New Line Engraving

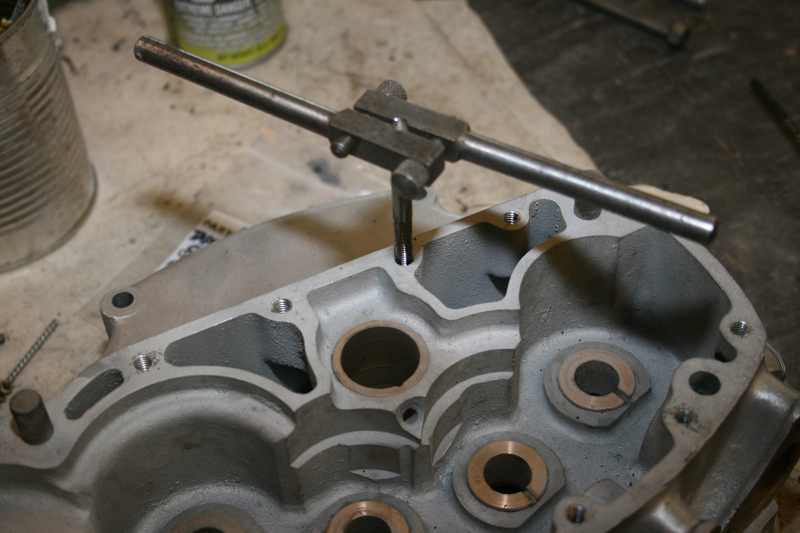

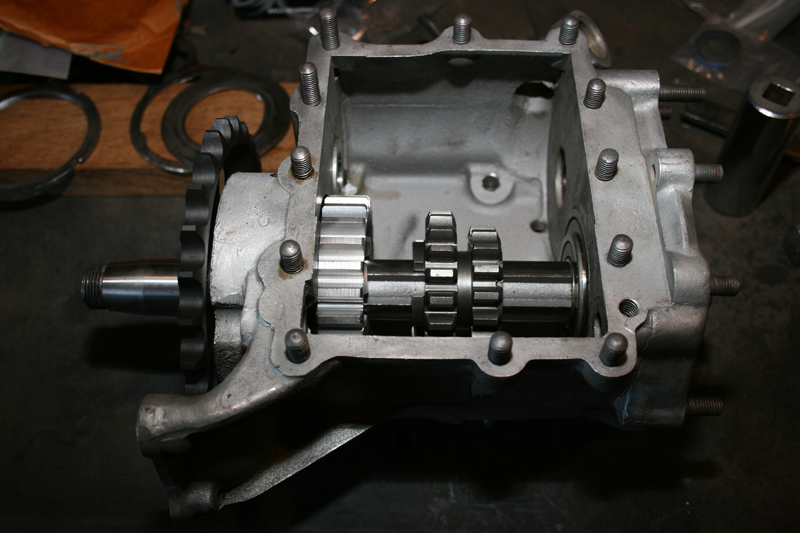

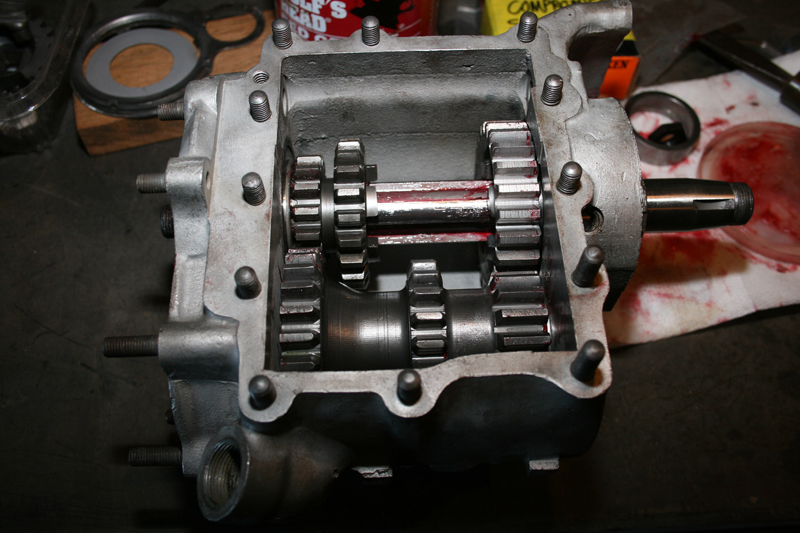

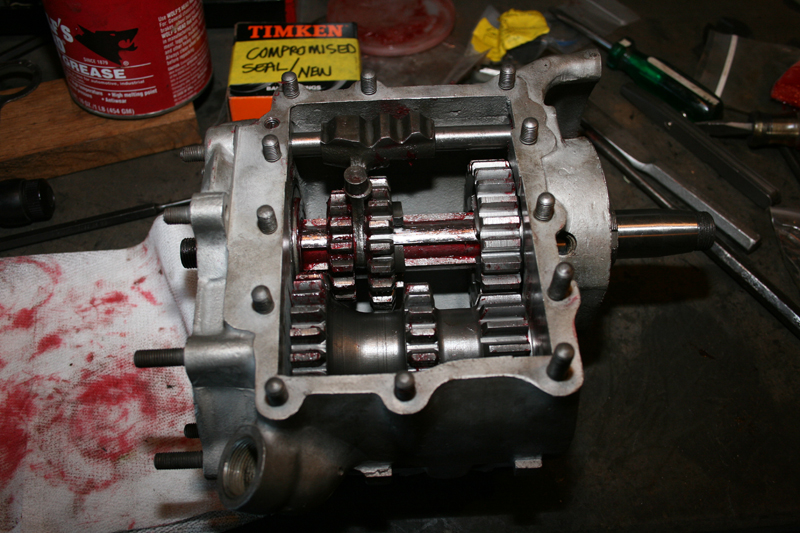

Rebirth of an American Classic: Transmission Rebuild

By Bandit |

We have already gained the support of many of the top compaines in the vintage motorcycle industry. If you would like to see your company’s logo included not only on the motorcycle, but also on every article, please contact me directly to learn more about our marketing campaign and advertising opportunities. EMAIL

|

|

|||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|