Road King 12/20/02 Part II

By Robin Technologies |

I couldn’t think or speak. I had a week and a half to insure that this puppy ran. I could sense fangs growing under my upper lip. I began to snarl as my fingernail extended beyond my cold hard hands. My eyes reddened, and I wanted to ride. Without the throttle cables I could use the cruise control, if it still worked. I could jam it into gear and fly. Frank hit me with a torque wrench. “We’re burnin’ daylight,” he snapped, “Let’s measure the cables and install the left Knuckle style grip.”

After wiping the grip end of the bar down with alcohol, the grip interior was coated with the rubber cement, that came with the grips. Then it was immediately slipped into place.

I snapped out of my Werewolf London fog. We measured the clutch cable then compared our findings with the throttle cables. As I suspected, lucky 13 inches to make up for the 12-inch taller bars that were an inch wider than the stock units. Frank made a B-line for the phone to call Barnett’s and ordered the cables. We were scheduled to roll up to the fleet center for a performance upgrade on Friday. It was Tuesday and the cables wouldn’t arrive until Thursday. It was going to be a close call. “Barnett has been around since Moby Dick was a minnow,” Frank said. I’ve been ordering custom cables from them since I was in my 20s and first influenced by Apehanger madness. “They are as reliable as the sun on the coast,” Frank continued, but I was still nervous.

We weren’t done yet. We torqued (15 foot pounds) the bars into place and began to cut and fit Goodridge brakes hoses, distributed by Barnetts and Custom Chrome. Another delicate operation.

The King has dual disc brakes and the fittings had to be installed just right, tightened properly and finally torgued into place. From the bottom of the triple-trees we used the stock measurement to the calipers from the existing junction under the trees. The new lengths of Goodridge hose were cut with the largest, strongest side cutters I had. Before any fittings were installed we slipped a 2-inch piece of black 3/8-inch diameter shrink tubing over the hose. Next a chromed pinch fitting was slipped over the cable. Frank brought the tools and supplies including a tool to spread the braided hose after the rubber housing was stripped away to allow the new fitting to be installed.

Stripping the rubber sleave back from the end about an inch.

Here’s all the components involved in the process.

The tool used to spread the braided steel shield.

Then a small brass round furl (like a brass ball-bearing with a hole in it) is slipped over the plastic lining. It must be pushed to the point where the internal brass ridge meets with the end of the plastic liner. The other half of the fitting with the long tube is shoved into place. In each case we clamped the fitting between two sheets of leather then began to tighten the sleeve onto the fitting. In each case they were a bear to tighten down indicating that we had succeeded in a strong, secure grip.

The spreading process involves shoving the tool into place and swiveling it to make sure the braided area is spread consistently.

Installing the furl is simple, just slip it on carefully then push it into place. But, inspect the inside to make sure the plastic hose is against the interior ridge.

Now tighten the pinch fitting. Note the leather pads in the vice to prevent damage to the banjo fitting. These puppies are tough to tighten down, take your time.

Here’s another way to hold the banjo fitting for final tightening. Be careful not to bend or damage the sealing surfaces.

Note the two bronze washer/gaskets on either side of the banjo fittings for proper sealing which is critical to your brakes.

After each line was carefully constructed, they were installed on the bike after some jockeying with the Goodridge billet junction under the tree which fit precisely.

For some reason, this Goodridge junction mounted extremely snug between the fork tube guards. For awhile we thought we were in trouble.

We followed the original routing of the stock brake line through the nacelle. With the lines in place we torqued them down (17-20 foot pounds). I took the easy way of bleeding the brakes. I pulled on the lever gently allowing the bubbles to pass through the master cylinder. It took a while, and I had to keep filling the reservoir as the the lines drained the supply.

We used the stock 12-point fittings which torqued down easily to 17-20 foot pounds, which seemed like a lot.

We had completed all that was possible for Tuesday and I swung my leg over the saddle once more. As fire and smoke poured from my ears Frank crept out of the garage and into the night.

Thursday morning I paced the vast porch in front of the headquarters waiting for the UPS man. The truck sped past without a hint of slowing. I called Frank, he called Barnetts. I called the Fleet center after finding that the cables wouldn’t arrive until Monday morning, guaranteed. We had an American Rider magazine deadline, but more importantly I had a run-to-Arizona-deadline for the following Friday. I started pacing the garage and bowing to the new 16-inch apes. I knew, by the power of the Ape, we would succeed.

At 9:00 a.m. in my boxer shorts, Monday morning, I met the UPS man and signed for the Barnett package. I started to lube all the cables then decided that I should get dressed.

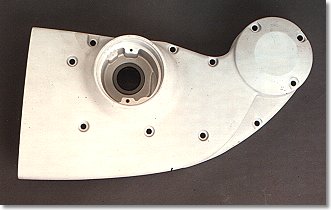

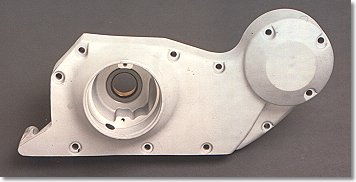

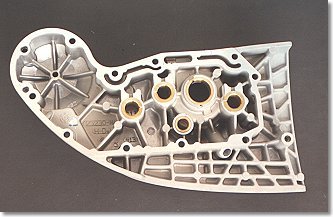

In order to install a new clutch cable the face of the transmission must be removed. I was surprised that this was the first item that I ran across on the King that was a pain in the ass to install. The entire exhaust system had to be loosened all the way back to the rear muffler isolator. before the clutch release housing could be removed.

With large clip ring pliers the throw-out mechanism was set free to release the clutch cable which virtually snapped into place. Then the cover was spun to allow the cable housing to unscrew. Next the new cable was fed along the same route as the stock job.

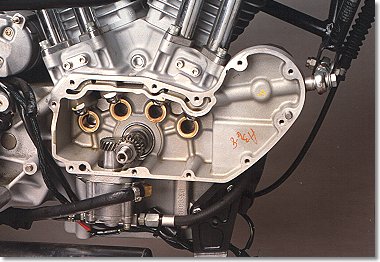

Once the clutch release cover is removed and the clip ring snapped out, you can see the outer ramp with the coupling ready for the cable.

If you look close the cable has been fed through the hole and is heading towards home.

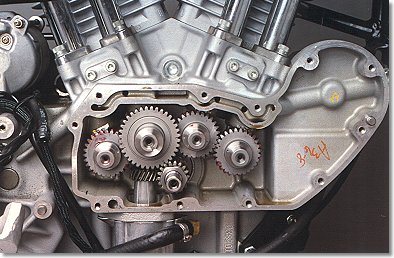

Now with the new cable attached the outer ramp heads back into position. Watch you don’t tilt the case. The ball bearings will escape.

This shot shows the entire clutch release assembly complete. Remember as you reposition the clip ring to put the sharp edge up for the most secure bond.

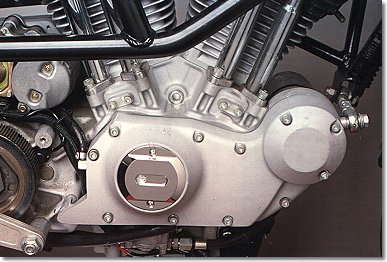

We discovered that we had a lot of slack and rerouted the clutch cable outside the front motormount to eliminate some. Then the tranny cover gasket was wiped clean and the cover replaced (torqued to 10-12 foot pounds), then refilled with tranny fluid to the appropriate level with the bike upright and the dipstick threads just touching. We filled it to the top dipstick mark, about 3/4 of a quart capacity.

With this assembly you spin the cover onto the cable, not visa-versa.

According to the book, the torque specs call for 10-12 foot pounds of torque to snug up the clutch release cover.

With a 9/16 box end wrench snug the cable housing down with a new o-ring attached.

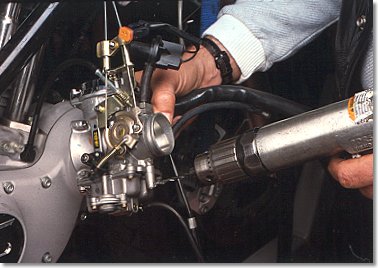

We jacked-up the gas tank to afford us access to the fuel injection throttle cable routing. With the three tank mounting bolts removed the tank was lifted easily until a chunk of wood could be wedged under the front of the tank. Then I figured out which cable was what. With a small Crescent wrench, I loosened the throttle cable adjusters and took out all of the adjustment to allow lots of cable slack.

The unit with the small spring around the cable at the throttle body end was the push cable. I fed the braided cables through the runners as if they were stock cables. You will note, if you attempt this, that there is a Cruise Control connection in one of the stock cables at the neck. We unplugged it with trepidation. I wasn’t sure what havoc it would cause. I hadn’t tried the Cruise control. As it turned out, it’s a sensor to kill the control, if you back off the throttle abruptly.

Lubing throttle cables starts with wrapping the cable housing with a little masking tape to create an oil container. Fill it with a light 3-in-1, silicone, or Marvel Mystery oil and let it seep into the housing. Fill it several times.

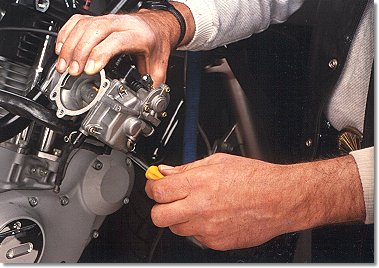

Feed the cables up through the throttle casing. With a little force they will snap into place.

Make sure to grease the brass barrel before installing it to the cable end. The grease will help hold the barrel in place.

With the Barnett cable set at the most slack position, slip the barrel and cable onto the greased throttle guide grove.

This is not a good shot of installing the cables into the guide slots in the intake module, but it’s easy. Just make sure you have the right cable in the right slot. It doesn’t hurt to grease them which we forgot.

Here’s the cables in position. That odd short cable on the side is the cruise control job.

Make sure you oil the throttle cables before they are snapped into the throttle housing on the bars, because the spring clips that hold them into place are a bitch to remove. The cables were both put into place with brass rollers, “After you grease the throttle and cable runners with a Q-tip,” Frank reminded me. Be careful not to lose those tiny brass suckers. I was told later to try to adjust the cables evenly under the throttle and make sure you have slack in both lines so you don’t have continuos drag on the cable fittings.

Here’s the throttle body in place waiting for the front brake mastercylinder.

According to experts, you should adjust the cables so that the adjustment screws are approximately equal in length. My adjustment had to be straightened out at a later date.

Finally we replaced the air cleaner backing plate using Phillips screwdrivers to hold the gasket in proper position. Next the breather hoses had to be pushed onto the head fittings and lined up with the air cleaner element. Lastly the cover was installed. It was time to ride.

But not so fast Kimosabe. We had to install the riser cover, the nacelle trim and the headlight assembly. We were hauling ass.

The actual breather fittings hold the air cleaner backing plate into place.

Use small Phillips screwdrivers to hold the air cleaner gasket aligned.

Push the hoses into place keeping in mind that they feed into the air cleaner element.

This little nut and screw are a bear to replace but must be handled before the nacelle strip can be installed.

This slightly out-of-focus shot shows the little stud that slips through the nacelle. Make sure the strip is locked into the riser cover slot before you tighten the nut.

Tighten the nut lightly with blue Loctite to keep it from rattling loose.

Don’t forget to plug the headlight in before you install it, like I did.

Install the headlight assembly with all eight black screws. Leave the bright adjustment ones alone, unless you lowered your bike. Then it needs adjustment.

We could screw the riser down with the Phillips screws and replace the snap-on ignition ring last. I still don’t like the way it fit and need to check it again.

By noon on Monday we had completed the Highbar installation and I was itching to hit the road. We had moved our appointment at the fleet center from Friday to Monday morning, then to Monday at noon. We didn’t roll up to their doors until 1:30 p.m. and Alan, the master mechanic announced that he was leaving at 4:00. We were burnin’ daylight once again. Would the pressure every end?

The final Frank shot with one hand hanging outside of a van window. I want to thank Frank for the use of his tools and his photographic and technical skills. Those elements and my bumbling hands make these techs as complete as they are. Believe me, it’s a bastard to build a bike, write a tech and take the shots at the same time. We’ve done it before, but a team efforts helps a helluva lot.

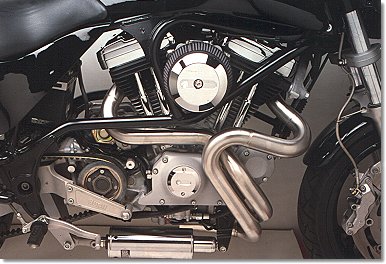

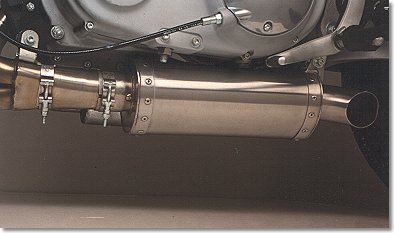

Next, we’ll install a performance package with Screamin’ Eagle heads, cams, air cleaner and two into one exhaust that we had jet hot coated. Hang on.

–Bandit

The Magnificent 5-Ball Factory Racer Featured

By Robin Technologies |

.jpg)

Editor’s Note: Our 5-Ball factory racer was feature in Heavy Duty Magazine in Australia recently. It’s the largest selling custom bike mag Down Under. The story and the photos were handled by the amazing Smilin’ Doc Robinson, the longtime tech editor. I’ve left the story alone for your viewing pleasure. Enjoy.–Bandit

Many interesting and colourful characters populate the biker world and Keith “Bandit” Ball walks tall among them. And not only because he tops out at six-foot five inches. Lifetime biker, author, longtime Easyriders’ editor, custom bike builder, salt racer, founder of the premier web site Bikernet.com, Bandit is all this and more.

Get him settled in the comfortable lounge seat in his Los Angeles abode, pour him a stiff whisky, and sit back as he shares tales of the road, some that would make your hair curl, others that are genuinely side-splitting and always among them, lessons to be learned about life.

I figured that the best way to introduce this build to HEAVY DUTY readers is to give it to you in Bandit’s own words: “For decades guys have built vintage- looking scooters with late model drive-trains. Hell, I built another one at Strokers Dallas in the ’90s. Before I dreamed of it, Arlen Ness built a ’20s vintage scooter and sidecar around a Sportster engine.

Randy Simpson built vintage kit bikes. Don Hotop built some of the finest vintage-styled customs and recently I saw a ’20s styled bike at the SEMA show in Las Vegas built by the Shadley Brothers for House of Kolors. Beautiful piece. So I ain’t the first by a long shot. But there is something in the air recently about respecting the old iron and bringing it back to life. Some of it has to do with restrictions, and building older bikes is unrestricted. Some of it has to do with nostalgia and some is just a wild departure from the last project. I’m excited every year about this learning process.”

I asked Keith to sum up the vision that drove this build: “Well I built it in the teens vintage style, but with my height and long limbs I had to scale it up a bit. It’s built for long miles, with floorboards, a sprung seat, rubber grips, tall gearing and a spare gas tank. Every custom motorcycle build is an adventure. It takes me from one crazed time in my wild life to another. Fortunately, I’m not spilling my guts about another woman I lost during a knuckle-busting build. But this build did represent turning points. I’m rapidly closing in on my mid-sixties and about ready to sign up for Social Security. It also represented our stinky economy.”

Bandit is such an industry icon and it is not surprising that many of the leading lights of the motorcycle aftermarket were involved in this build, blokes like Ron Paugh of Paughco, leading manufacturer of custom parts and accessories for the past forty-three years, Rick Krost of US Choppers, Chica, who needs no introduction, Gard Hollinger of LA Choprods and HEAVY DUTY photographer Glenn Priddle who made the sweet seat.

Here’s Bandit again: “The key to the success of this project is the drive train. I sought a Crazy Horse V-Plus, 100-inch engine for several reasons. It has a classic design, renewed performance, cool looks and a left-side carb. I coupled it to a JIMS 5-speed transmission with a Baker kicker unit and Baker N1 shifting drum, so I can run the tank shifter and find neutral without a problem. The rocker clutch system I put together from old H-D parts while I fabricated the tank shifter.”

When he hasn’t got a fast motorcycle between his legs, or a whiskey in one hand and a beautiful redhead in the other, Bandit is happiest welding, soldering, wrenching, milling and turning metal in his secret and damn well-equipped lair beneath Bikernet HQ. His other love is writing, usually upstairs in his 1923 shop, behind his glass-topped Panhead-motor desk, rattling his computer keyboard, churning out another fiction book, a book for motorbooks, magazine articles (sometimes for HEAVY DUTY), or news, or one of dozens of tech articles for Bikernet.com.

And for those of you who are truly interested in the real guts of bike building, let me recommend reading the whole story of this build on the Bikernet.com web site. It runs over some eleven parts and is well illustrated with photographs showing each and every step of this build.

If you only read one part of the full story, make it Part 6 where you’ll see the immense amount of work that went into the rear fender fully detailed as master metal shaper Chica gets to work. But once again, I strongly recommend you read the whole thing as a salutary lesson on just what goes into a ground up build. Without the space limitations of a magazine Bandit is able to show and tell stuff that you won’t find elsewhere. To find it, go to Bikernet.com and click the Free Departments button and select Techs and Bike Builds and scroll backward through the various articles until you find Part One and take it from there.

I really dig this bike in every aspect; the concept of honouring old iron in this way, the marriage of old school looks with a nod here and there to practicality and safety, given that brakes back in the first two decades of the twentieth century were mighty primitive to say the least. I love that shifter in all its brassy mechanical glory, the vintage touches like the chain oilers and the leather strap holding down the battery and the cool fuel tank mounted up top to extend the bike’s range.

Having examined it closely, both during construction and in its completed state, I can attest that the fit and finish all over is excellent and detail touches like the pin striping are icing on the cake. Keith thanks Sin Wu for her part in this build and reckons this woman is a keeper, and I can understand that. This bike is a beauty and will look just as cool in fifty years from now. Way to go Bandit, I’ve seen several of your other builds but with this one you’ve climbed a pinnacle. HEAVY DUTY is proud to feature it in our pages.

BIKERNET EXTREME GUTS&BOLTS TECH CHART

ENGINE

Type: Crazy Horse Power Plus 100

Capacity: 100ci

Cases: Stock

Crank Stock

Bore: 3.874″

Stroke: 4.25c

Heads: Stock

Ignition: Thunderheart

Carburetion: S&S Super E

Manifold: Stock

Air cleaner: powder coated by Worco

Exhaust: Bandit built

Muffler: Stainless Scorpion from John Reed

Estimated power: 80hp

TRANSMISSION

Year: 2006

Type: JIMS

Number of gears: 5

Gearchange: Bandit built

Baker N1 Shift Drum

Clutch: BDL

Primary drive: BDL Classic powder coated by Worco

Rear Drive: Exile chain

SUSPENSION

Front: Paughco narrow tapered leg springer

Triple Trees: steel from Paughco

Mods: 2″ under length

Rear: Rigid U.S. Chopper design

WHEELS

Front: Black Bike dimpled 23″

Tyre: Avon

Brake calipers: GMA by BDL

Brake rotor: H-D

Brake lines: John Reed

Rear: Black Bike dimpled 23″

Tyre: Avon

Brake caliper: Exile

Brake rotor: Exile Sprotor

FRAME

Type: US Choppers vintage rigid

Make: Factory Racer by Paugho

Year: 2009

Rake: 30 degrees

Seat: Glenn Priddle

CONTROLS

Handlebars: Narrowed Flanders

Grips/levers: H-D, BDL/GMA

Risers: DPPB bronze dogbones

Master cylinder: GMA front

Mirror: Lowbrow

Headlight: pinstriped by George the Wild Brush

Footpegs/forward controls: Paughco vintage footboards

Rear brake master cylinder: H-D

Speedo/tacho/oil pressure: Biker’s Choice Vintage Sportster

Taillight: powder coated by Worco

Other modifications: rocker clutch system made with old H-D parts, Phil’s Speed Shop wiring harness and ignition system, alternator charging system by Spyke

GUARDS/TINWORK

Front guard: missing

Rear guard: Chica

Fuel tank: Paughco

Trim: gone

Oil tank: Paughco

Other modifications: Vintage H-D tool box and brake linkage by Paughco, Reserve gas tank by Mike Pullin

COMMENTS: This bike was built in the teens vintage style, but built for long miles with footboards, sprung seat, rubber grips, tall gearing, and spare gas tank. The plan was to ride to Sturgis, but I never got out of Dodge. Now the plan is to ride it to Arizona for the too broke for Sturgis run to Salome, a little sun burnt town in the middle of nowhere. But it has a very cool or western saloon on the edge of town.

Partners in Crime:

Sturgis 2000 – Part 1 Whiskey, Women and the Open Road (Continued)

By Robin Technologies |

|

Continued from page 1…… I was about to reach for the phone book one morning, on an ass-saving spring hunt, when the mail arrived with an invitation to the Harley-Davidson new-model announcement. At that point I was spending every extra moment in the garage and interruptions were a problem. But the factory has always been supportive and I couldn’t miss the new bike review so I signed on for the event. It took place in Pasadena and all the moto-journalists from the Southern California region were on hand. Occasionally during the presentation I would peer at the list in my pocket and go to the dingy corner where the heads were to make a call about chrome or parts, or I’d call headquarters to check in with the crew. Some years the Harley announcements indicate business as usual at the factory with only minor changes. This year was a vast contrast to the status quo. It was immediately evident the company was making strides to capture a larger segment of the aftermarket with its accessory production pace and the focus on custom parts. The models radiated custom touches. They had finally truly lowered a bike, the new Lowrider Dyna. Road Glides were getting much more engineering attention. Performance was advancing quickly with a Holley Carb introduction and big-inch motor kits. Some of the new paint schemes reached deeply into the custom culture for colors and designs.

Then they came to the new narrower, lighter, police model for 2001. Cop bikes didn’t mean a hill of beans to me, but I scanned the more agile machine that is now available for individual sales and they’re cheap. Dan Ackroyd should get a new one. I noticed springs under the solo cop saddle and immediately jumped to my feet. Two representatives from the factory rushed to my side. “Can we help you answer any questions about the new police model?” one of the engineers asked. I started babbling about this stretched rigid I was going to ride to Sturgis and the two contemporary thinkers backed away as if my radical concept might rub off on them. I ordered a set later that day. They proved to be … well you’ll see. The frame was sent to the powdercoater, the chrome went out and the sheet metal was shipped to Harold’s. The waiting game began while I chased any missing parts. By the time the sun was blazing in the single window of our tiny headquarters, the frame was back in the garage and up on a towel-covered lift. The chromer made me wait another day. I was in the midst of a bolting-together orgy when the dark-haired one appeared in the doorway of the Bikernet den, peeling out of her threads.

Her alabaster skin looked like cream flowing into a hot cup of coffee. The satin shaved surface was too delicate to touch. What the hell is a biker to do when heaven is standing nude in the doorway? The crew was looking at 34 days until departure. I was looking at green eyes, a sensitive smile and … priorities men, priorities. It was a factor of hours and parts availability, plus watching for problems. Everything was seriously locktite drenched, tightened and tightened again. I notice a weak link immediately in the wheel spacing. This was an odd, uncalled-for operation. You buy wheels, they come with spacers. You install them and it’s a done deal. You go for a ride. So what was the problem? The tubes had been cut and collars added to assist with holding the grease near the bearings, and to hold the spacer centered when the axle was removed. They weren’t shabby. The dilemma made me second-guess my installation. I checked and rechecked the life-threatening problem. If I left them alone, I would certainly be a candidate for a high-speed wobble. If I set them up too tight, I could burn up the bearings in the desert and be left alongside the road to fry in the sun. Something had to be done to correct the wheels or find out where I went astray. With spacers the correct length, the wheels and brakes could be installed for the last time and anything that could reach final assembly made me smile and saved time. We were frustrated. I centered the wheel and began to space the P.M. Calipers. Something wasn’t right. There was .020 slop in the center spacer that pre-loads the Timken bearings. I was blown away and stayed up until 2 a.m. with a sheet of glass and wet and dry sand paper trimming the spacer down while insuring the flat parallel surface to the bearing race as left intact. I finished uncertain of the tolerances. Later I found that the tolerance prescribed by the factory is .004 to .014. It is recommended that with aluminum hubs you should lead your figure to the .004 side. There was another weak link and Harold mentioned it as soon as he received the mounted Sportster Tank. “That tab system is a little shaky, Bandit.” What could I do? I had two 1/8-inch-thick straps that ran the entire length of the tank and out both ends by three inches. At the last minute I eliminated one because I felt it would be too difficult to bondo. The tank was now in Harold’s hands and time was running out. If I had sent the bare frame to Harold, he would have mounted the gas tank by his proven method. The decision had been made and I would be forced to live with it. We kept moving. Ah, but there was another adjustment that lurked in the back of my mind, although Giggie from Compu-fire checked my installation and gave it a thumbs up. I was sketchy about the primary drive adjustment. I had slipped the original inner-primary O-ring between the engine cases and the motor plate for vibration relief. Bad move. The BDL belt was too tight.

There was no slack in the belt and I wanted some. I had to loosen the transmission, unbolt the motor-plate from the engine and move the tranny forward as much as possible. It worked out perfectly, but just in case, I ordered a spare belt (I broke a primary belt in ’97 outside Denver). Giggie from Compu-fire helped kick off the wiring with the installation and timing of the Compu-fire single fire ignition. With it in place sans the Voes switch (this is a chopper, right?). About that time, a tall Asian in a flowered bikini and a black towel strolled past the headquarters on her way to secluded Cabrillo Beach. The entire crew was distracted. It wouldn’t be the last time Sin Wu captured my concentration. She became our lunch time mascot, dropping in from time to time to check the progress and tantalize us. The rear wheel had yet to be spaced properly. It suffered from the same malady as the front wheel and the last thing I wanted storming through my brain at 5 a.m. on a highway in the middle of nowhere was my wheel spacers. We were forced to remove the rear wheel again. I had built in a stud for the hydraulic brake switch behind an exhaust pipe as part of the exhaust bracket. The notion was to hide that ugly bastard yet make it accessible if need be. As it turned out, Joker Machine builds a micro brake switch into their forward controls. Ultimately a dice was drilled and tapped to conceal the stud. Just as I finished the wiring, the paint was delivered. Harold and I discussed the paint scheme at length. The first problem was the frame paint. We were limited to a bright metallic blue. I sent Harold a chunk of square tubing painted the same color to match. He studied it and went to work. We discussed white pearl or cream colored flames and he decided to add a silver accent. We couldn’t decided what color to pinstripe with. We discussed red, pink (no way), even green, but nothing jumped out at us. When Harold called and said he’d pinstriped it gray, I choked. It sounded drab, lifeless. A week later, after clear coating and drying, the paint was shipped. I had become best of pals with the UPS guy, who showed up daily. When he showed up with a small package he’d be greeted with a long face from a disappointed crew member. “We need bigger boxes and more of ’em,” Wrench told him one morning. We did. We were biting our nails, watching the clock and the calendar. The plan called for a running motorcycle two weeks before the takeoff date. The first stretch of road to Phoenix was 450 miles of blistering desert and I was riding alone. I needed a break-in period. Most years we had little or no break-in time. Last year the Excelsior-Henderson had no miles on it after High Tech Custom Cycles customized the rowdy 85-inch monster. I had it for two days before leaving. The first day the front brake kept locking up and we discovered chrome chips in the front master cylinder. With that fixed, I thought I was good to go until the starter motor blew up in my face the night before takeoff. We made arrangements with Bert’s Cycle Mall in Azusa to fix it. I hired a guy to drive my truck, my bike and me to Bert’s, where we sat for half the afternoon while they replaced the starter and some fried bushings, then retuned the bike with a new computer program. Dr. Hamster and I sat in their waiting room with our gear and waited patiently for the verdict. It finally came with a road test by the main mechanic. He rolled out of the parking lot without making eye contact with either of us.

The year before that, it was the street stalker built essentially by Bartels’ Harley-Davidson. Before that, it was the touring chopper built by Jesse James. All of the above are professionals who are constantly building bikes, have mechanics and extensive tools and supplies. I’m not, and my guys all work on old Panheads. So when we took on these projects as non-professional, skirt-chasing, beer-drinking geeks, we wanted more time to correct all the bullshit mistakes we would make. As it turned out, we didn’t make any more mistakes than the pros had in the past. Plus the feeble, leaning Bikernet headquarters held nearly every tool we needed to keep the operation going. As the sheet metal arrived, Sin Wu and I slipped into the basement of the vast Bikernet headquarters to un-box, un-peanut, un-bubble wrap and un-cellophane the paint. The gray pinstripe was perfect, the finish clean and classic. We made love in the basement in celebration and as a tribute to the notion that this underground slab of concrete would soon become the international Bikernet shipping and receiving department. Fuck, life can be exciting. Sin went home and the brothers began to install the tank and sheet metal.

We were moving fast. Time was running out and days seemed to disappear. At one point, we had the grandiose notion that the bike would be ready for the Exceptional Childrens’ Beach Ride in Ventura, California. We couldn’t make it. Then the Calendar Girl Show loomed. What was once the Mikuni Bike Show at the Santa Monica Airport had transcended into the Calendar Girl/White Bros. Show in a small park near the looming bow of the Queen Mary. Cool location, but could we have the bike up in time? Wiring went easy with the internal tubing installed in the frame by Daytec. Tubes ran from the back of the seat post to the top motormount and down the seat tube to the oil pump. I quickly discovered that I could run two switches in the top motormount and Giggie suggested a polished aluminum plate to conceal the switch backs and the single circuit breaker. Giggie emphasized that we use mil spec (military specification) or Marine switches. I had purchased plastic Marine switches but wasn’t confident in them. I wanted to head over to Neptunes Electronics for some heavy duty mil spec metal units, but it never happened. The wiring continued with two switches to control all the electronics on the bike. An on/off switch turned on the ignition and the brake and tail lights and energized the high/low beam switch. The on-off-on switch controlled the headlight and that was all. For the starter switch we used Custom Cycle Engineering’s new mechanical push button, which mounts directly to the starter solenoid of the Compu-Fire starter. It’s the cleanest switch in the world and works like a champ, but if your pipes come anywhere close to the switch, watch out. It’s easy to burn your mitt when the bike is hot. Plus the switch is bolted to the right side of the bike and down low. If that’s going to be a problem with the carb and reaching the throttle, you need to consider those obstacles. It worked like a champ on this rigid with the pipes we chose. For our pipes, we picked a set of Samson 2 1/8-inch drag pipes for a Dyna Glide because they don’t make pipes for rigid frames. From a performance standpoint, I wanted the 98-inch S&S stroker motor to run as effortlessly as possible. I had discovered by mounting a Compu-Fire single-fire ignition system on the touring chopper that it calmed that stroker motor, so I did the same on this one. I wanted to even the exhaust system for firing balance. One pipe was 12 inches longer than the other and hung down too far, which would hamper ground clearance. We took two inches out of the down stroke. Wrench gas-welded it back together with a coat hanger. Then we cut the pipe to even the lengths to 27 inches. That seemed precariously short for the diameter of the exhaust, so we took two Samson exhaust muffler baffles, cut them in half and installed them. Finally, for styling purposes, we asked James Famigatti to scallop the ends of the pipes to contour the shape of the Milwaukee Iron fenders. We called Mikuni America and asked about the carburetor. Lee, the man responsible for every Mikuni carburetor that flies into the states for motorcycles, asked, “For your bike?” “Yep,” I said. “You’re going to install it?” “Yep,” I said. “Forget it,” he said, “Bring the bike to me. We’ll make sure the intake is correct and the cables match, and that the bike runs.” I didn’t know what to make of it, but I did as I was told and delivered the bike to the Mikuni factory. With the swift action of Barnett cables, S&S and American Iron Horse, the correct intake was procured for the tall barrel S&S stroker engine that tucked the polished 42-mm slide carburetor in close to the engine. They fired and tuned the bike for the first time. The technician, Bryan, warned us to back out the air mixture screw half a turn when I reached the altitudes of Denver. They also installed a large tear-drop, exposed K&N air cleaner that would afford the engine all the air it wished to gulp. Time was running out. We still needed miles on the bike but we had no speedometer and no idea where to put it. The cable was in the garage and the drive unit had been installed on the front wheel, but the actual speedometer was nowhere to be found. Then it dawned on me that the ’84 Shovelhead in Dallas had just the speedometer we needed, but planned not to use. I called and asked the crew at Dallas Easyriders to ship the unit quick and it was on its way.

|

Sturgis 2000 – Whiskey, Women and the Open Road on the Blue Flame

By Robin Technologies |

|

Unlike many years in the past, I didn’t rely on any builders to make the deadline for the trek to the Bad Lands. The Bikernet crew handled building two road-sizzling chops in two and a half months. I’ve got to tell you that it felt good to get back in the garage amongst the socket sets, grinders and torches. Although the drunken work ethic was strong, several times during late-night wrench fests I came mighty close to firing myself. However, since I was one of a very small crew of volunteer wrench merchants, it didn’t make solid sense. Nutboy was there until he couldn’t handle the clogged pressure cooker in the garage, so he grabbed 30 college coeds and flew to Ireland. Never did get the meaning of all that, but it sounded like good fun. Agent Zebra flew in from Miami to pitch his movie 1%er for the 43rd time and came by the Bikernet headquarters to assist with his bike. I quickly discovered that the bull riding champion/survivalist can’t turn a doorknob, never mind a wrench. Renegade lost his patience and we kicked him out of the garage and told him to return to Hollywood and, “Don’t come back without a contract.” Wrench was constantly on hand, Snake was constantly drunk and Oz could never get away from his computer monitor long enough to help, but he was a constant source of phone-advice.

Renegade came to the garage daily to criticize everything from finish choices to components. That bastard would make a kid cry about going to Disneyland. He hasn’t had a good word to say since I met him in 1972, but he’s my brother. Whatta ya gonna do? Our challenge was to build two bikes and ride to Sturgis for the first Sturgis Bikernet Chop-Off, a bike-building competition between Bikernet East and Bikernet West. Great plans don’t always pan out, yet become blessings in disguise. We finally turned one world-class custom, which was not the road bike we needed, into two distinctly different asphalt gobblers. Were we up for the task? Did we have the skills and tools to build the bikes? Would they run once they were completed? Had I lost my eye for solid choppers or my mechanical touch? Keep in mind as this saga unfolds that this (Bikernet) is a start-up business, competition and life change. I’ve been helping people get their businesses, projects and products off the launching pad for almost 30 years. Now, faced with no paycheck and no expense account we attempted to build two bikes from the ground up just months before Sturgis 2000. In addition, we would be judged on who had the coolest chop and whipped the other son of a bitch from its designated homeland, namely Miami and San Pedro in Los Angeles, to South Dakota. With the Bandit II dismantled, we stood back and evaluated the situation. We had another set of wheels hanging around in the garage and miscellaneous other parts. Agent Zebra is a short, wiry asshole, so the Paughco frame went to him, along with a set of H-D custom wheels and rotors. We split the P.M. brakes between the two bikes. We checked our leaking bank accounts and began ordering parts. Since the frame for my ride had to be ordered from Daytec, we started on the Agent’s bike first. The original Bandit II narrow glide went back on the stretched Paughco Softail along with P.M. brakes and Harley Thunderstar wheels and rotors. The 88-inch CCI engine slipped into place along with the Baker five-speed transmission. As the days rolled along, we plucked more parts from my pile just to keep the starving Agent’s project rolling. The frame was still painted with the Bandit II theme, along with the tank, so we stuck with it. A Fatboy rear fender was fitted over the 160 Avon Tyre and sent to Phil Stadden for paint along with the West Coast Choppers front fender. The completeness of the 88-inch Rev Tech engines made the project much smoother. The Baker Transmission was a jewel to deal with and improved the ride immensely. With a few odds and ends from the extensive, “if you need it – they have it,” Custom Chrome catalog, the Zebra special was coming together. We had a minor clearance problem with the frame and engine. Fitting the 160 tire under the fender was tight and making the brakes work was a bit of a challenge. In no time, the bike was running and on a custom-painted Gold Rush Semi heading to Miami for the Agent. We shipped it to Eddie Trotta at Thunder Designs in Fort Lauderdale for break-in, a seat from the infamous Keith and tweaking.

Of course the Agent couldn’t leave well enough alone and he decided to have special panels painted on the sides of the tank and fender announcing his arrival. The paint work was handled by Eddie Meeks in record time, but it still sliced away at Zebra’s time for break-in. The crew at Thunder Cycle, with less than a week before kick-off, pulled burn-outs up and down the tourist-packed streets of Fort Lauderdale in an effort to spin the miles onto his new odometer. All right, you’re beginning to get the picture, but there are more obstacles to come. The young muscular Zebra had this Germanic girlfriend. She was tall and thin, with super-model looks, natural blond hair and blue eyes like you only see in Scandinavia. She had a whisper of a voice and could speak very little English. Unbeknownst to the Agent, he was in love. He bought her furniture, a car, took care of her expenses, etc. while he was working. Suddenly his Los Angeles highlife went into the shitter and he was forced to move quickly to Miami and set up a crack house in the middle of Cuban controlled South Beach. The competition didn’t take to the blond boy from Kansas, and they dropped a pill in lovely Nicole’s soup. She immediately fell out of love with Zebra and the world stopped. Not only did he lose his girl, but his access to a car and all the furniture in his pad. His massive, attack-trained Malinwa dog, Apache, went homeless on the streets of Miami while Zebra panhandled for coins along the route to the Badlands. On the other hand, my life was a circus of broken promises. Calling in a favor, I contacted Milwaukee Iron for fenders. I had helped Randy build his business from the beginning, yet when the fenders arrived, the UPS dude stood there with a unexpected C.O.D. request, and there I was, in the middle of a financial no man’s land. That scenario happened more than once. We even had a Bikernet sponsor sign our contract then go back on their signature. But “give up” is not written in the Bikernet mantra, so we rolled up our sleeves and kept wrenching. For every time I felt screwed, there was a bright star, a blessing in disguise, a pearl in our soup. The Weerd Bros. from Phoenix not only were helpful beyond our wildest dreams, but their product turned out to be a superb ride and a life saver. Harold Pontarelli, owner of H-D Performance, called me one day about a year and a half ago, while I was still at Easyriders, and said that for running some of his bikes in the mag and for being a friend, he wanted to comp me a paint job. I thanked him profusely, but never expected to take him up on the offer because I knew my days at the page factory were numbered. A couple of months after I left, Harold called me to say his promise was good whether I ever did a thing for him again or not. I was blissfully floored. Custom Cycle Engineering, which you can see featured on the site in our Panhead project section, has always been a good friend. I run their rubbermounted dogbone risers on all my bikes.

Finally, Ron at Paughco never hesitates to assist in any way he can. So for every screwing, there was a blessing. Finally, a company I had never had a chance to work with came to my rescue in the final hour. It’s odd that some of the companies I had assisted for years couldn’t step up. Yet the folks at Joker Machine, whom I hadn’t worked with, went out of their way to assist. Geoff and Diane were there when I needed them and I will be forever grateful. Their machine shop is impeccable, the product precise and well thought through, and examples showed up on the road to Sturgis from time to time. They take particular care with polish and chrome. Being flexible is a necessary evil to building a custom. When the bell tolled and the slick-as-a-perfectly-curved-tit Daytec frame arrived, we had five weeks to build the Blue Flame from the ground up. The custom Daytec rigid was ideal for the 14-over Weerd Bros. front end. Tony Day said of the specifications, “An Eddie Trotta formula frame.” Eddie from Thunder Designs in Fort Lauderdale builds a hard-riding stretched Softail chopper that makes riding like first-time sex. The question at that point was whether to send the frame with the sheet metal to Harold in Vacaville, Calif., or to powdercoat in three days and have the chassis building underway while the sheet metal was under the spray gun. Powder has its color limitations. It’s tremendously durable and strong, but comes in few colors. We found a company in Orange County, Primo Powder Coating (Huntington Beach, that has an unheard-of two-stage powder, so I was relieved not to build another fucking black bike. I love black scoots, but I’ve built one too many, including the Excelsior-Henderson last year and the ’97 Street Stalker from the prior year. It was time for a change. While waiting for the welds to cool, we debated whether to powder coat. While wondering, we narrowed a ’50s cop-bike solo seat one inch and Nuutboy fabricated a steel frame and pivot point. A bracket on the frame was modified to allow the seat to glide up and down with rear spring action. Two studs were welded in the center of the frame rails to correspond with the studs on the underside of the seat, but what about springs? The old Bates springs were never strong enough to carry the weight of a man. I had to find a set of 4-inch tapered coil springs that would handle my ass to the Bad Lands. It was June and the sun was as hot as my love life. Something sparked and a dark-haired bundle of intrigue entered my lonely existence in the middle of a bar fight. Although the pressure was on, she remained a soft-spoken Valium in tight pants. She was like finding a jewel in a trash bag full of crushed beer cans. Initially I was concerned, curious and watchful as she roamed in and out of my days, bringing coffee cake in the morning and sex at night. Her schedule fit well with work on the Web site, books and bikes. She showed up on my doorstep at 10 p.m. and slipped out at midnight. She had an 11-year-old daughter whose school was up the street from the Bikernet headquarters. She’d swing by in the morning on her way to work with packs of oatmeal and creamers, stay a few minutes and disappear out the door. She didn’t ask questions, didn’t seem bothered by anything and loved sex — my kind of woman. But I was focused on the goal to build the bikes and driven to ride to Sturgis.

I was about to reach for the phone book one morning, on an ass-saving spring hunt, when the mail arrived with an invitation to the Harley-Davidson new-model announcement. At that point I was spending every extra moment in the garage and interruptions were a problem. But the factory has always been supportive and I couldn’t miss the new bike review so I signed on for the event. It took place in Pasadena and all the moto-journalists from the Southern California region were on hand. Occasionally during the presentation I would peer at the list in my pocket and go to the dingy corner where the heads were to make a call about chrome or parts, or I’d call headquarters to check in with the crew. Some years the Harley announcements indicate business as usual at the factory with only minor changes. This year was a vast contrast to the status quo. It was immediately evident the company was making strides to capture a larger segment of the aftermarket with its accessory production pace and the focus on custom parts. The models radiated custom touches. They had finally truly lowered a bike, the new Lowrider Dyna. Road Glides were getting much more engineering attention. Performance was advancing quickly with a Holley Carb introduction and big-inch motor kits. Some of the new paint schemes reached deeply into the custom culture for colors and designs.

Then they came to the new narrower, lighter, police model for 2001. Cop bikes didn’t mean a hill of beans to me, but I scanned the more agile machine that is now available for individual sales and they’re cheap. Dan Ackroyd should get a new one. I noticed springs under the solo cop saddle and immediately jumped to my feet. Two representatives from the factory rushed to my side. “Can we help you answer any questions about the new police model?” one of the engineers asked. I started babbling about this stretched rigid I was going to ride to Sturgis and the two contemporary thinkers backed away as if my radical concept might rub off on them. I ordered a set later that day. They proved to be … well you’ll see. The frame was sent to the powdercoater, the chrome went out and the sheet metal was shipped to Harold’s. The waiting game began while I chased any missing parts. By the time the sun was blazing in the single window of our tiny headquarters, the frame was back in the garage and up on a towel-covered lift. The chromer made me wait another day. I was in the midst of a bolting-together orgy when the dark-haired one appeared in the doorway of the Bikernet den, peeling out of her threads.

Her alabaster skin looked like cream flowing into a hot cup of coffee. The satin shaved surface was too delicate to touch. What the hell is a biker to do when heaven is standing nude in the doorway? The crew was looking at 34 days until departure. I was looking at green eyes, a sensitive smile and … priorities men, priorities. It was a factor of hours and parts availability, plus watching for problems. Everything was seriously locktite drenched, tightened and tightened again. I notice a weak link immediately in the wheel spacing. This was an odd, uncalled-for operation. You buy wheels, they come with spacers. You install them and it’s a done deal. You go for a ride. So what was the problem? The tubes had been cut and collars added to assist with holding the grease near the bearings, and to hold the spacer centered when the axle was removed. They weren’t shabby. The dilemma made me second-guess my installation. I checked and rechecked the life-threatening problem. If I left them alone, I would certainly be a candidate for a high-speed wobble. If I set them up too tight, I could burn up the bearings in the desert and be left alongside the road to fry in the sun. Something had to be done to correct the wheels or find out where I went astray. With spacers the correct length, the wheels and brakes could be installed for the last time and anything that could reach final assembly made me smile and saved time. We were frustrated. I centered the wheel and began to space the P.M. Calipers. Something wasn’t right. There was .020 slop in the center spacer that pre-loads the Timken bearings. I was blown away and stayed up until 2 a.m. with a sheet of glass and wet and dry sand paper trimming the spacer down while insuring the flat parallel surface to the bearing race as left intact. I finished uncertain of the tolerances. Later I found that the tolerance prescribed by the factory is .004 to .014. It is recommended that with aluminum hubs you should lead your figure to the .004 side. There was another weak link and Harold mentioned it as soon as he received the mounted Sportster Tank. “That tab system is a little shaky, Bandit.” What could I do? I had two 1/8-inch-thick straps that ran the entire length of the tank and out both ends by three inches. At the last minute I eliminated one because I felt it would be too difficult to bondo. The tank was now in Harold’s hands and time was running out. If I had sent the bare frame to Harold, he would have mounted the gas tank by his proven method. The decision had been made and I would be forced to live with it. We kept moving. Ah, but there was another adjustment that lurked in the back of my mind, although Giggie from Compu-fire checked my installation and gave it a thumbs up. I was sketchy about the primary drive adjustment. I had slipped the original inner-primary O-ring between the engine cases and the motor plate for vibration relief. Bad move. The BDL belt was too tight.

There was no slack in the belt and I wanted some. I had to loosen the transmission, unbolt the motor-plate from the engine and move the tranny forward as much as possible. It worked out perfectly, but just in case, I ordered a spare belt (I broke a primary belt in ’97 outside Denver). Giggie from Compu-fire helped kick off the wiring with the installation and timing of the Compu-fire single fire ignition. With it in place sans the Voes switch (this is a chopper, right?). About that time, a tall Asian in a flowered bikini and a black towel strolled past the headquarters on her way to secluded Cabrillo Beach. The entire crew was distracted. It wouldn’t be the last time Sin Wu captured my concentration. She became our lunch time mascot, dropping in from time to time to check the progress and tantalize us. The rear wheel had yet to be spaced properly. It suffered from the same malady as the front wheel and the last thing I wanted storming through my brain at 5 a.m. on a highway in the middle of nowhere was my wheel spacers. We were forced to remove the rear wheel again. I had built in a stud for the hydraulic brake switch behind an exhaust pipe as part of the exhaust bracket. The notion was to hide that ugly bastard yet make it accessible if need be. As it turned out, Joker Machine builds a micro brake switch into their forward controls. Ultimately a dice was drilled and tapped to conceal the stud. Just as I finished the wiring, the paint was delivered. Harold and I discussed the paint scheme at length. The first problem was the frame paint. We were limited to a bright metallic blue. I sent Harold a chunk of square tubing painted the same color to match. He studied it and went to work. We discussed white pearl or cream colored flames and he decided to add a silver accent. We couldn’t decided what color to pinstripe with. We discussed red, pink (no way), even green, but nothing jumped out at us. When Harold called and said he’d pinstriped it gray, I choked. It sounded drab, lifeless. A week later, after clear coating and drying, the paint was shipped. I had become best of pals with the UPS guy, who showed up daily. When he showed up with a small package he’d be greeted with a long face from a disappointed crew member. “We need bigger boxes and more of ’em,” Wrench told him one morning. We did. We were biting our nails, watching the clock and the calendar. The plan called for a running motorcycle two weeks before the takeoff date. The first stretch of road to Phoenix was 450 miles of blistering desert and I was riding alone. I needed a break-in period. Most years we had little or no break-in time. Last year the Excelsior-Henderson had no miles on it after High Tech Custom Cycles customized the rowdy 85-inch monster. I had it for two days before leaving. The first day the front brake kept locking up and we discovered chrome chips in the front master cylinder. With that fixed, I thought I was good to go until the starter motor blew up in my face the night before takeoff. We made arrangements with Bert’s Cycle Mall in Azusa to fix it. I hired a guy to drive my truck, my bike and me to Bert’s, where we sat for half the afternoon while they replaced the starter and some fried bushings, then retuned the bike with a new computer program. Dr. Hamster and I sat in their waiting room with our gear and waited patiently for the verdict. It finally came with a road test by the main mechanic. He rolled out of the parking lot without making eye contact with either of us.

The year before that, it was the street stalker built essentially by Bartels’ Harley-Davidson. Before that, it was the touring chopper built by Jesse James. All of the above are professionals who are constantly building bikes, have mechanics and extensive tools and supplies. I’m not, and my guys all work on old Panheads. So when we took on these projects as non-professional, skirt-chasing, beer-drinking geeks, we wanted more time to correct all the bullshit mistakes we would make. As it turned out, we didn’t make any more mistakes than the pros had in the past. Plus the feeble, leaning Bikernet headquarters held nearly every tool we needed to keep the operation going. As the sheet metal arrived, Sin Wu and I slipped into the basement of the vast Bikernet headquarters to un-box, un-peanut, un-bubble wrap and un-cellophane the paint. The gray pinstripe was perfect, the finish clean and classic. We made love in the basement in celebration and as a tribute to the notion that this underground slab of concrete would soon become the international Bikernet shipping and receiving department. Fuck, life can be exciting. Sin went home and the brothers began to install the tank and sheet metal.

We were moving fast. Time was running out and days seemed to disappear. At one point, we had the grandiose notion that the bike would be ready for the Exceptional Childrens’ Beach Ride in Ventura, California. We couldn’t make it. Then the Calendar Girl Show loomed. What was once the Mikuni Bike Show at the Santa Monica Airport had transcended into the Calendar Girl/White Bros. Show in a small park near the looming bow of the Queen Mary. Cool location, but could we have the bike up in time? Wiring went easy with the internal tubing installed in the frame by Daytec. Tubes ran from the back of the seat post to the top motormount and down the seat tube to the oil pump. I quickly discovered that I could run two switches in the top motormount and Giggie suggested a polished aluminum plate to conceal the switch backs and the single circuit breaker. Giggie emphasized that we use mil spec (military specification) or Marine switches. I had purchased plastic Marine switches but wasn’t confident in them. I wanted to head over to Neptunes Electronics for some heavy duty mil spec metal units, but it never happened. The wiring continued with two switches to control all the electronics on the bike. An on/off switch turned on the ignition and the brake and tail lights and energized the high/low beam switch. The on-off-on switch controlled the headlight and that was all. For the starter switch we used Custom Cycle Engineering’s new mechanical push button, which mounts directly to the starter solenoid of the Compu-Fire starter. It’s the cleanest switch in the world and works like a champ, but if your pipes come anywhere close to the switch, watch out. It’s easy to burn your mitt when the bike is hot. Plus the switch is bolted to the right side of the bike and down low. If that’s going to be a problem with the carb and reaching the throttle, you need to consider those obstacles. It worked like a champ on this rigid with the pipes we chose. For our pipes, we picked a set of Samson 2 1/8-inch drag pipes for a Dyna Glide because they don’t make pipes for rigid frames. From a performance standpoint, I wanted the 98-inch S&S stroker motor to run as effortlessly as possible. I had discovered by mounting a Compu-Fire single-fire ignition system on the touring chopper that it calmed that stroker motor, so I did the same on this one. I wanted to even the exhaust system for firing balance. One pipe was 12 inches longer than the other and hung down too far, which would hamper ground clearance. We took two inches out of the down stroke. Wrench gas-welded it back together with a coat hanger. Then we cut the pipe to even the lengths to 27 inches. That seemed precariously short for the diameter of the exhaust, so we took two Samson exhaust muffler baffles, cut them in half and installed them. Finally, for styling purposes, we asked James Famigatti to scallop the ends of the pipes to contour the shape of the Milwaukee Iron fenders. We called Mikuni America and asked about the carburetor. Lee, the man responsible for every Mikuni carburetor that flies into the states for motorcycles, asked, “For your bike?” “Yep,” I said. “You’re going to install it?” “Yep,” I said. “Forget it,” he said, “Bring the bike to me. We’ll make sure the intake is correct and the cables match, and that the bike runs.” I didn’t know what to make of it, but I did as I was told and delivered the bike to the Mikuni factory. With the swift action of Barnett cables, S&S and American Iron Horse, the correct intake was procured for the tall barrel S&S stroker engine that tucked the polished 42-mm slide carburetor in close to the engine. They fired and tuned the bike for the first time. The technician, Bryan, warned us to back out the air mixture screw half a turn when I reached the altitudes of Denver. They also installed a large tear-drop, exposed K&N air cleaner that would afford the engine all the air it wished to gulp. Time was running out. We still needed miles on the bike but we had no speedometer and no idea where to put it. The cable was in the garage and the drive unit had been installed on the front wheel, but the actual speedometer was nowhere to be found. Then it dawned on me that the ’84 Shovelhead in Dallas had just the speedometer we needed, but planned not to use. I called and asked the crew at Dallas Easyriders to ship the unit quick and it was on its way.

“It’s good to go,” he finally said without looking up. In the midst of rush-hour traffic, we rolled onto the freeway toward Sturgis.

The year before that, it was the street stalker built essentially by Bartels’ Harley-Davidson. Before that, it was the touring chopper built by Jesse James. All of the above are professionals who are constantly building bikes, have mechanics and extensive tools and supplies. I’m not, and my guys all work on old Panheads. So when we took on these projects as non-professional, skirt-chasing, beer-drinking geeks, we wanted more time to correct all the bullshit mistakes we would make. As it turned out, we didn’t make any more mistakes than the pros had in the past. Plus the feeble, leaning Bikernet headquarters held nearly every tool we needed to keep the operation going. As the sheet metal arrived, Sin Wu and I slipped into the basement of the vast Bikernet headquarters to un-box, un-peanut, un-bubble wrap and un-cellophane the paint. The gray pinstripe was perfect, the finish clean and classic. We made love in the basement in celebration and as a tribute to the notion that this underground slab of concrete would soon become the international Bikernet shipping and receiving department. Fuck, life can be exciting. Sin went home and the brothers began to install the tank and sheet metal.

We were moving fast. Time was running out and days seemed to disappear. At one point, we had the grandiose notion that the bike would be ready for the Exceptional Childrens’ Beach Ride in Ventura, California. We couldn’t make it. Then the Calendar Girl Show loomed. What was once the Mikuni Bike Show at the Santa Monica Airport had transcended into the Calendar Girl/White Bros. Show in a small park near the looming bow of the Queen Mary. Cool location, but could we have the bike up in time? Wiring went easy with the internal tubing installed in the frame by Daytec. Tubes ran from the back of the seat post to the top motormount and down the seat tube to the oil pump. I quickly discovered that I could run two switches in the top motormount and Giggie suggested a polished aluminum plate to conceal the switch backs and the single circuit breaker. Giggie emphasized that we use mil spec (military specification) or Marine switches. I had purchased plastic Marine switches but wasn’t confident in them. I wanted to head over to Neptunes Electronics for some heavy duty mil spec metal units, but it never happened. The wiring continued with two switches to control all the electronics on the bike. An on/off switch turned on the ignition and the brake and tail lights and energized the high/low beam switch. The on-off-on switch controlled the headlight and that was all. For the starter switch we used Custom Cycle Engineering’s new mechanical push button, which mounts directly to the starter solenoid of the Compu-Fire starter. It’s the cleanest switch in the world and works like a champ, but if your pipes come anywhere close to the switch, watch out. It’s easy to burn your mitt when the bike is hot. Plus the switch is bolted to the right side of the bike and down low. If that’s going to be a problem with the carb and reaching the throttle, you need to consider those obstacles. It worked like a champ on this rigid with the pipes we chose. For our pipes, we picked a set of Samson 2 1/8-inch drag pipes for a Dyna Glide because they don’t make pipes for rigid frames. From a performance standpoint, I wanted the 98-inch S&S stroker motor to run as effortlessly as possible. I had discovered by mounting a Compu-Fire single-fire ignition system on the touring chopper that it calmed that stroker motor, so I did the same on this one. I wanted to even the exhaust system for firing balance. One pipe was 12 inches longer than the other and hung down too far, which would hamper ground clearance. We took two inches out of the down stroke. Wrench gas-welded it back together with a coat hanger. Then we cut the pipe to even the lengths to 27 inches. That seemed precariously short for the diameter of the exhaust, so we took two Samson exhaust muffler baffles, cut them in half and installed them. Finally, for styling purposes, we asked James Famigatti to scallop the ends of the pipes to contour the shape of the Milwaukee Iron fenders. We called Mikuni America and asked about the carburetor. Lee, the man responsible for every Mikuni carburetor that flies into the states for motorcycles, asked, “For your bike?” “Yep,” I said. “You’re going to install it?” “Yep,” I said. “Forget it,” he said, “Bring the bike to me. We’ll make sure the intake is correct and the cables match, and that the bike runs.” I didn’t know what to make of it, but I did as I was told and delivered the bike to the Mikuni factory. With the swift action of Barnett cables, S&S and American Iron Horse, the correct intake was procured for the tall barrel S&S stroker engine that tucked the polished 42-mm slide carburetor in close to the engine. They fired and tuned the bike for the first time. The technician, Bryan, warned us to back out the air mixture screw half a turn when I reached the altitudes of Denver. They also installed a large tear-drop, exposed K&N air cleaner that would afford the engine all the air it wished to gulp. Time was running out. We still needed miles on the bike but we had no speedometer and no idea where to put it. The cable was in the garage and the drive unit had been installed on the front wheel, but the actual speedometer was nowhere to be found. Then it dawned on me that the ’84 Shovelhead in Dallas had just the speedometer we needed, but planned not to use. I called and asked the crew at Dallas Easyriders to ship the unit quick and it was on its way.

With a couple weeks left, I called Joker Machine daily. I didn’t want to press, but I was going out of my mind. My contact, Geoff, had faced some health problems and decided that smoking was his cure. I didn’t want to add to the stress of building high-precision, very costly components that were already on back order. I considered myself a nuisance so I was trying to tread lightly. The staff at Joker was more than helpful and I finally got the call from Geoff. “Come on out and we can bolt on the parts right here. I’ve even found a guy around the corner at Greased Lightening who will make up the brake lines. We finally got the stuff back from chrome, but as usual, all the elements aren’t perfect. You’ll have to roll with one polished piece. The others were sent back to be rechromed.”

I respected his desire for perfection and that he had paying customers breathing down his neck, so I was perfectly happy to take whatever he had. Jay from Station 34 in San Pedro, a cool restoration shop built in an old gas station down the street, volunteered to haul me out to Azusa to the Joker Machine facility. Jay from Japan works with the Japanese Easyriders Magazine and wheels and deals with bikes back and forth to Japan. He was also building a rigid to ride to Japan until I helped him make a contact with the Harley-Davidson fleet center and he was able to borrow a Road Glide. The cheater. Anyway, we loaded the Blue Flame into the back of Jay’s ’79 ranchero and hauled it out to Joker, where we installed the forward controls. Then we rolled a couple blocks to Greased Lightening where the owner, Mike Ingle, custom made the hydraulic brake lines for the front and rear brakes. We bled and tested them and loaded the bike for the return trip to Pedro and the first start up. Mike’s shop is small, but his engine building facility is well equipped. He’s experienced and ready now to take on building engines for a larger clientele. He told us that when bleeding brakes, smearing a tad of grease on the threads of the bleeder nipple prevents air bubbles from creeping around the threads and results in a more positive bleed. An hour later, we pulled up in front of the hot rod body and paint joint around the corner from the headquarters. Henry the proprietor and Bob, the owner of one of Henry’s creations, came scrambling out of the corrugated steel building to check the metallic blue monster sticking way out of the back of the baby blue Ranchero. Using Henry’s driveway for an assist to Jay’s ramp, we unloaded the bike easily and fired it to life for the first time. In the back of my mind I planned to use Eddie Trotta’s break-in scenario where he rides the bike for one mile then tweaks, the next day he rides it for 10 miles and tweaks some more, then 50 miles, and so on. I liked the notion and the bike rumbled easily but idled too high. I rode it around the block and discovered a number of tweaks that needed to be addressed immediately. The formula was working. We pulled the bike into the garage as the dark-haired beauty arrived. We celebrated the occasion with more than just a drink. The night was gone in a blur of sex, sweetness and excitement at bringing the beast to life.

I’ve been building bikes for 30 years and the exhilaration of a metallic accomplishment that can carry you across the country is still the same. It’s something like sex and winning the lottery. Although nothing compares to sex, like, well … more sex. We’ll leave that for another discussion. I had less than 10 days left when I took the bike for its 10-mile excursion. It ran fine, but the tightness of the belt was bothersome. Something was rubbing on the final belt. The rear wheel spacing was slack and there was still no speedometer. The rear fender was finding its home and the bolts needed to be tightened. The new front brake line needed to be secured and we discovered some industrial wire cable ties with rubber inserts that would do the trick. We removed the inserts and polished the aluminum, and we had a couple of custom hydraulic hose guides. I mounted one to the Weerd Bros. lower triple tree by drilling and tapping a small hole, but I made sure to go in about an inch so I had plenty of thread depth. I also made sure I had enough fasteners to have them match if and when I ran the speedometer drive. I had 10 days to put 500 miles on the bike and dial it in for the 2000-mile jaunt across the desert to the Black Hills. With another round of tweaking under my belt, I rode the bike down the coast for breakfast an put another 50 miles on it. I pulled into a gas station to refill and couldn’t get the gas cap off the Sportster tank. It was a carefully manufactured super clean custom cap that fit right down on the surface of the tank. Damn it looked clean, but the gripping edge of the cap was less than an 1/8-inch thick and a hair off the surface of the new paint. With little surface to grip, it wouldn’t budge. I stood in the station perplexed. I knew I would run out of fuel before I returned to headquarters. Unlike most of the stations in L.A., this one actually had a technician, and a wrench who spoke English. On top of that, the man was generous with his tools, another rarity. I borrowed his largest pair of channel-locks and a rag that I draped over the cap and the top of the tank. The cap came loose. Another item to be tweaked. When the weekend came for the calendar show, the bike had a couple hundred miles on it and I had less than a week until departure. There was still no speedometer but the bike was running fine. I had yet to respace the rear wheel, but two women wanted my company at the show and how could I possibly resist? The sun was ablaze as the girls followed me into the check-in area where I planned to display the bike with Joker Machine’s fine rides and then at the Mikuni booth, which sat alone on the edge of the water without any bikes or babes around it to draw the crowds to their product. I ran into a girl who I had once come very close to dating on a regular basis, Lexy, a blond bomb shell with tiny feet and a skirt that could have been made out of one of my Hawaiian shirt sleeves. She dripped with sexiness as I greeted her. The dark-haired beauty at my side stared at the youngster in the stretched-on skirt and her emerald eyes glistened with some mysterious feminine emotion. Sweat beaded on my forehead and the sun hadn’t even crested the horizon yet. The show was flawless and I escaped early to log on more miles and spend some quality time with the lovelies who chaperoned me through the bikinis and chrome. I continued to ride whenever I could while making arrangements for the trip. A noise nagged me and I suspected the BDL system, which is the easiest thing in the world to install if you watch the spacing and the initial alignment. If I ever install one again, I’ll know just how to go after it, and the thing will be a breeze. I also noted some aluminum shavings in the clutch basket. I kept riding, adjusting and tightening the Joker Machine mirror, which was very flexible and sturdy. The Joker controls worked perfectly and I found a couple CCI frame clamps to hold the clutch cable in proper alignment. Two days before departure I pulled the rear wheel for balancing and fixing the spacing. This time a neighbor had loaned me a flat belt and disc sander and I immediately took too much off the spacer and had to take it to the local shop for shims. The next morning I was at Century Motors first thing. When I asked about shims, the mechanic looked at me with disgruntled eyes, stroked his long beard and said, “I’ll check the washer drawer.” I jumped in the flamed Bikernet T-bird and hauled over to California H-D for an assortment of shims, which I quickly took back to Century Motors. With the proper alignment and the wheel carefully balanced, I returned to the garage for installation. Then I decided the noise was coming from the clutch and began to dismantle it. I couldn’t seem to knock the clutch nut loose and more loose ends began to appear. It was Wednesday, with a day left before a crack-of-dawn departure on Friday, but the signs were pointing at a postponement until Saturday morning. Thursday morning I had lists in my pockets and notes on the Panhead Desk. The spare bedroom was becoming the packing department with my bedroll, my HA leather vest, a Prison Blues denim jacket from Chrome Specialties, my ditty bag, extra sunglasses and shirts. The bedroll was rapidly being buried under shit I threw on the bed every time I wandered down the hallowed Bikernet hall.

With each new creak of the feeble hardwood floor, I thought of something else. Sun Block, bungee cords and the battery charger for the cell phone. Just before noon, as I was writing news for the Web site, the UPS man showed up with a small square box. It contained the Custom Chrome Speedometer. I stopped to sign for the package, confirmed what it was, then headed to the garage. The Blue Flame stood majestically in the dim light as I studied its sleek form. She was beautiful and gave off a sense of alertness and anxiousness to hit the road. I wanted to load up and cut a dusty trail that minute, but I had lists to check off, calls to make, the news to finish. I was waiting for Bikernet patches to arrive. The UPS man had already left. If I waited one more day, perhaps? I looked at the speedo and set it on the bench. I went back to the glass Panhead and kept hammering on the news, although my heart was heading for the door.

That afternoon, I finished the weekly update and jammed for the tilting garage. Nuutboy had already broken under the extreme pressure and hauled ass for foreign shores. Wrench checked into rehab for the 24th time. He had been awake for three weeks and was beginning to look like the guy from the “Living Dead.” Japanese Jay threw up his hands, jumped on the bike from the Harley fleet center, and hauled ass for the border. Renegade bitched and moaned, but under his breath, after smoking several joints, said, “Nice bike.” We knew then I was good to go. I dialed Giggie in a frenzy, “Could I have knocked the clutch hub loose?” “Don’t sweat it,” he said, “It’s tight, but what about the plates?” We had installed a plate wrong and metal-to-metal grating was taking place. With that fixed, I moved on to a shim to prevent the starter jackshaft from peeling away the aluminum on the inside of the BDL support bracket. I was beginning to feel that tight feeling of a motorcycle without any loose ends, except for the speedometer, which I was holding in my hand behind the top triple tree. It seemed to fit and I ran the cable. No problem except the cap holding the cable into the bottom of the speedo didn’t seem to work. It came with another cap and that didn’t work either. My mind raced with options. Throw it into the street and forget it? Find something with the correct thread size and make a cap? That seemed to be an option and I jumped into the flamed T-Chicken and roared to the marine store.