The Cyril Huze Project

By Cyril Huze |

FLASHBACK

On the night of Jan. 10, 2001, Arlen Ness, Jesse James, Paul Yaffe and I were on different planes to the same destination: the Italian Chopper Custom Bike Show of Padova, near Milan, one of Europe’s most important motorcycle events. I cross the Atlantic a couple times a year, but it had been five years since I walked the streets of Rome, Milan or Firenze. The night flying from one continent to the other is very short because of the six-hour time difference. So when I fly west to east, I never sleep. I am excited like a kid because I love Italy so much. It is the birthplace of so many talented artists who influenced the world with their architecture, fashion and automotive designs. I spend the night drinking too much coffee and chewing peanuts (because I can’t smoke) and reflecting on what my shop has produced during these last months and on what I would like to build the next season. In the U.S., everybody and his brother (plus me!) are building choppers. In Europe, the craze is called bobbers (I would like to make one, too!). But what else to build? I am not supposed to follow trends. I have to surf on them. It’s what people expect from me. Thinking of new projects has always been for me like a sweet torture. So, I torture myself all night.

ESPRESSO ANYONE?

It’s time for breakfast before landing in Milan. “Espresso anyone?” asks the too-sexy Italian-American flight attendant. Espresso at breakfast? Did she say espresso with an S? Or expresso with an X? She said eSpresso. I am thinking eXpresso, like …so Express. That’s it! I’ve got a bike theme. I request my eXpresso, she gives me an eSpresso plus a cool theme for a fast-looking bike. If I weren’t seat belted in because of turbulence, I would jump to kiss her. Hey, of course, it will not be an ode to coffee (although hot java has always been a very good friend when building bikes). A bike with a chopper attitude and a street racer stance. A chopper to race? Attitude and speed would have to be mixed together. Is it possible?

BEFORE DAYTONA – DAYTONA – AFTER DAYTONA.

The time from before to after Daytona is a custom builder’s nightmare. There is too much to do, too much to fix at the last minute, too many people to see at the same time. Expresso is buried in the left side of my brain. The only decision I am able to make is the choice of the frame. It’s an easy choice. Since October, I’ve been teamed up with Peter Penz to market a Softail frame that I named “Kool Kat.”

I sold a lot of frames and rolling chassis, but there’s been no time to produce my full-blown “Kool Kat” custom.

The frame accepts the new Avon 250 mm rear tire with a stock belt. That’s very important when you run a big mill because 1 1/8 belts are a third less strong than 1 ½ inch belts.

The absence of the middle post and the battery relocated in the swingarm gives a lot of room in the rear, making the bike built on this frame look very agile, exactly what I am looking for. I offer this frame in many different geometries (rake from 36 to 44, stretch from 3 to 6 inches, front leg from minus 2 to plus 6 inches). And if that’s not enough, you can add one of our raked triple trees (3-5-7-degree) and you have your own ultra-custom frame. In my shop, I pick one with a 5-inch stretch and 42-degree rake.

EXPRESSO FIRST SKETCHES

The frame high neck gives Expresso the stance I need to mean attitude. Now I need to express(o) speed. It jumps to my mind that it can come from the swingarm. This part of the bike has long been neglected even on sharp customs. Only during the last few years has the swingarm evolved. A lot of custom builders are now going to the single sided swingarm, which looks very cool. But I want something different. Instead of focusing first on the overall shape of the bike, I try to imagine my “speedy” swingarm. I see it pointed in the rear, reaching far behind the axle, with stepping all along. I love computers but I hate to use CAD programs because the learning curve is very steep and usually it’s much easier and faster for me to use a pen and paper to jot down my ideas. But I know in advance that Bob, my master fabricator, is going to turn me down if I don’t bring him a sketch perfectly scaled (hey, he knows how to protect himself). The swingarm is all drawn in my mind but in a few days my briefing will have to be “engineered” as much as possible. I must CAD design this swingarm. Loading the CAD program on my computer gives me the same chill as filling out my tax return…but I have no choice. I spend about eight hours struggling with the keyboard and designing the Expresso swingarm. It’s not perfect, but in line with what I am looking for. From there I go back to paper and pen to make a first sketch of the bike.

INTERNAL AFFAIRS

I am always somewhat nervous when I present my ideas to my crew. Building bikes is not an exact science. Will they be excited? If not, I know it’s going to be a so-so bike. So, evidently, I will not build it. If they are as excited as I am, it’s going to be a great bike. Keeping the excitement alive from the first day to the time the bike is ridden for the first time is part of my job. Custom shops are horizontal structures. Everybody needs everybody. It’s a team effort. Passion is the cement holding us together for ventures lasting many months. I am the composer. My melodies have to first be approved. Then I will write the orchestration and will transform myself into music director. But that is another story.

Thursday is D-day. The crew in charge of this custom project (Bob, Sean, Brigitte) invades my office. I talk for half an hour, show the sketches, suggest a light …… paint job. (No I will not tell you the color right now because I reserve the right to change my mind, my special privilege. Then they give me the magic words: “Nobody’s done it before. That’s cool. We can do it. Let’s do it. When do we start it?”

Monday, of course. We always start on Monday because weekends are made to go somewhere. And it’s always somewhere out of the office that I find new ideas. And I still need a ton of new ideas to make Expresso a great custom. What I gave them is just the first draft.

Expresso Swingarm

When we start a new custom, there is a tradition that we respect religiously: We always start with what seems to us the most difficult part to fabricate. So, on this Monday morning, the swingarm is the first part of the bike that we lay down on the fabrication table. (a.k.a. the surgery table) The first decisions to make are:

1. The number of steps inside the swingarm.

2. The thickness of each step and which one is thicker (top or bottom?).

3. How the swingarm must look from inside.

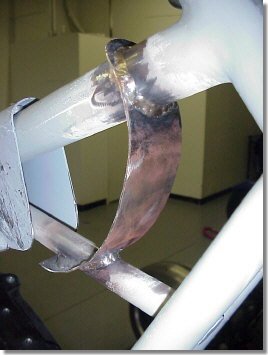

It’s my job and responsibility to make these decisions, but I would never obligate my fabricator to do anything without first convincing him, if necessary. Bob is in charge. He agrees immediately with me on the fact that: Steps always look better in odd numbers, so we keep the three steps as they appear on my sketch; The step on top will be higher. Each step must be about half the size of the one just above (to give fluidity to the lines), but the thickness of each step must look the same (as a matter of fact, they have to be a different thickness because they’re welded to the same back plate); Seen from inside the swingarm, no step will be visible because it would visually interfere with the wheel and brake designs.

Our “stock” swingarm is thick. It takes almost an hour for Bob to cut the pieces joining the main tubes of the swingarm — just the time I need to cut cardboard templates of the steps. It’s from these cardboard pieces that Bob cuts three metal pieces that he will adjust inside the swingarm. Then he will duplicate (reversed) these three metal steps for the other side of the swingarm. It’s already 80 degrees at 10 a.m. Bob has a lot of cutting and welding to do and he is already sweating. We close the bay and set the air conditioner at 75. I leave the fabrication room to work on a new chopper that I have to get started. But that’s another story… Bob and I have an agreement: I never come to check what he does. If he is stuck with a problem, he calls me immediately to decide a remedy. But if everything goes fine, he calls me only when the job is done and looks perfect to him. I estimate that the swingarm fabrication is a two-day job, including the cutting, trimming, welding and polishing. Good news — I won’t hear from Bob during these two days, and will resist to the temptation to check the work in progress (which is, for me, very difficult).

Two Days Later

Expresso gets its racy swingarm. We prime it because I hate to see a bike rusting during the fabrication and mockup process. To be sure it’s perfect, we attach it to the frame using Progressive suspension shocks. I immediately see a small imperfection that nobody saw before — a small bump on the lower part of the swingarm, just behind the rear axle. We correct it with a grinder and make a primer touchup. I already dream of mass producing this swingarm in steel or maybe billet aluminum. There’s a typical builder’s dilemma, however: How many need to be CNC machined to make it affordable to the public? How much money can I invest? Low cash flow has always been a custom builder’s main problem…

Expresso Juice

I have always been a fan of small, dry cell batteries. I use them on all my bikes. They can be easily hidden, placed in any position, and in a small package, their cranking power is double that of most standard wet acid batteries. They start big motors when the appropriate starter is used. Most times, I use small Odyssey batteries with 500 CCA and measuring only 6.69 inches long by 7.05 inches wide and 5.04 inches high..

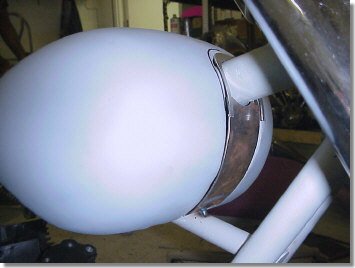

The frame kit that we sell includes a battery bottom plate bolted to the swingarm, and a top cover with slots to make the battery connections accessible. Rubber or metallic straps are enough to hold the battery securely in place inside the swingarm. But the battery still remains visible. Customizing is about hiding what doesn’t deserve to be seen. So, I must make this battery “disappear” as much as possible. I want to conceive a simple system that the motorcycle dealer or individual builder in his garage could easily fabricate.

It doesn’t take more than five minutes to agree with the boys on the kind of battery box to fabricate. Sean volunteers to make it and is already busy measuring the battery again to cut the six steel plates to be used to conceal it from view.

It’s very simple. Instead of using the base plate provided with the frame, the entire box will be bolted to the swingarm. A box is fabricated in such a way that it slides forward. Two small, flat screws will hold it in place. The front plate is conceived in such a way that the connections are not visible. Two holes are made for the battery cables to exit the box. A battery must be charged from time to time, but we don’t need access to the connections to do it. We will charge directly at the starter, which is easier and faster than unbolting the box.

Suddenly I realize that the box must stand perfectly vertical to the ground when the swingarm is in its definitive position with the engine, transmission and primary installed. It means that the portion of the swingarm where the battery box sits must be adjusted to correct the swingarm angle when the bike is on its weight. We postpone this job until we set up the definitive geometry of the frame, which is our next step. We just prime the battery box to keep it rust free.

Hiding the Oil Tank

The Kool Kat frame is sold with a custom stainless steel oil tank, small in size but big in capacity (4 quarts because it doesn’t contain the battery).

Four steel plates are also provided. They have to be welded inside the two openings on each side of the frame, making the oil tank disappear from view when the bike is looked at from profile. These side plates are not identical for each side because of the left kick-out of the frame to accept a 250 mm tire on an 18-by-9 rear wheel.

Frame Geometry

The most frequent questions (at least 15 a day) we receive through e-mail and over the phone, are:

1- I have a frame with such stretch, such rake. How long should my tubes be?

2- I lowered the rear of my bike 2 inches. How much should I rake to keep the bike horizontal?

3- I saw a bike in a magazine with a 10-inch over. I want the same look. How much should I rake my bike?

4- Etc…

The answer is: it depends!

Not all frames are born equal. A 5-inch backbone stretch doesn’t mean the same length on the top tube from one brand to the other. (Don’t ask me why.) The neck of different frames doesn’t stand at the same distance from the ground. Front leg stretch, lowered shocks or adjustable air shocks on a Softail are examples of other parameters that affect the geometry of a frame, its distance from the ground, and the overall look of the bike. When people require a 10-inch over front end, it means 10 inches over stock. But stock Harley bikes, depending on the model, have different front end lengths!

So, here’s how I set up the geometry of Expresso. I like my bikes to be a compromise between look and function. It means high enough to be rideable, and low enough to look good. I like them when they sit at 4 3/4 inches from the ground (meaning from the ground to the lower portion of the lower tube of the frame). It’s the distance I want when the bike carries all its components, with a biker of average weight seated on it. When the bike I customize is a dresser with floorboards, I increase this distance to 5 inches minimum. Same when it’s a two-seater.

On this project, I use Progressive Suspension shocks. I attach the swingarm to the frame and bolt the shocks to the frame and swingarm. I install the 18-by-9 rear wheel equipped with an Avon 250-by-40-by-18. (At this stage I am not preoccupied by the fact that the wheel is or is not perfectly centered in the frame) We mock up the bike with cases (our engine is not ready yet), a transmission, a starter, an inner primary and all the main components available in the shop to be close to the weight that the bike will have to carry. I take measurements and I realize that the Kool Kat frame with stock height shocks sits 5 inches from the ground. I know because the lower tube of the frame is parallel to the lift table when we put two pieces of wood, 4-by-4 plus 4-by-1, on the front and back of the frame.

Now we have to figure out the tube length to keep the bike parallel to the ground. First, Sean installs a triple tree. Then we lock a 21-inch wheel in the vise of the lift (with a piece of wood covered with carpet on each side of the tire to avoid scratching the rim). We run one neon tube through one of the holes of the triple tree, and move the frame on the table until the tube crosses the center of the axle of the front wheel (the opposite can be done, not moving the frame, by moving the front wheel back and forth, but it’s difficult to keep the front wheel from moving while taking measurements). Now I measure the total front end required. It’s the distance from the top of the triple tree to the center of the front axle. It’s exactly 34 inches. Now it’s easy to figure out the tube length I need. Because tubes sit about 7 ¾ inches from the bottom of the lower legs, I need tubes 26 1/4 inches long (Front end 34 inches – 7 3/4 inches).

At the shop, we always keep tubes in different lengths. All have internals (springs, seals, etc., pre-installed so that we don’t lose time when mocking up a bike). For information, 26 ¼ inch-long tubes are 2 inches over FXDWG stock tubes (24 ¼ inches).

I install the tubes in the lower legs, slide the front end in the triple tree and lock it. We tie down the bike in front (not under heavy pressure because we need to lift the bike to remove the pieces of wood under the frame). Our last exercise of the day is to jump on the bike to unfreeze the swingarm, and then to “ride” the bike on the lift to check again the distance from the ground. Sean is 195 pounds, quite a few pounds heavier than me. So, he “test rides” the bike while I take measurements. I am all smiles when I realize that the bike sits perfectly at 4.75 inches from the table, front and rear.

It’s 7 p.m. Sean proposes to celebrate with a cup of coffee at Starbucks, not far away from the shop. I know why. It’s this time of the day when pretty secretaries must do last minute photocopies at Kinko’s. And Kinko’s are always located next door to Starbucks. Or the opposite. Whatever. Sean is single again. Let’s make Sean happy. I’m gonna drink my eighth cup of coffee of the day, and probably go back to the shop to read my e-mails. Any questions?

Expresso Rear Fender

It seems that pointed rear fenders became my trademark. Not that I don’t like round fenders, short or long. We fabricate a lot of them, too. But my most recent bikes “Dreamliner” & “High Octane” had pointed fenders that were “imposed” by their themes. Since these 2 bikes are well known, everybody’s thinking: pointed fender = Cyril Huze.

When I think of “Expresso” it’s difficult for me to imagine something else than a sharp fender matching our already fabricated pointed swingarm. So, I guess that when the bike will be finished, I am going to reinforce my stereotype. It’s Ok with me because my next project is going to be very, very different. I like change. The boys too.

Anyone showing a bike with a pointed fender will tell you the same thing. Everybody, and I repeat everybody, is going to check: 1- if the pointe is centered on the tire 2- Move the fender right and left to see if the fender is strong enough to not vibrate. No way you can cheat with this kind of fender: 1- symmetry must be perfect 2- fender need to be “boxed” not to vibrate and crack the paint.

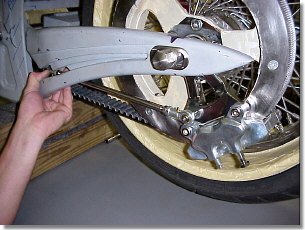

Before starting fabricating any fender, the most important step, the one conditioning success or failure, is to mock up the bike the way it’s going to ride: with 2 wheels aligned and perfectly centered in the frame. For the rear fender, we must mock up the bike with an engine (fake or not), a primary, a transmission, a rear wheel perfectly centered in the frame, and a belt adjusted at the right tension. Usually it’s the step of bike building when things begin to get scratched. Tape being less expensive than chrome, we tape, tape, and tape again all what is called chrome & polished aluminum. I recommend you do the same. You can trust us about this one.

First, we estimate what is the position of the wheel to be centered in the frame. For this, we mark the center of the 250 mm tire. Then, we run a thin blue (for visibility) painter masking tape along the frame backbone to the center of the tire. Any slight bend, and you know that the wheel is off center, and or turning right or left. When our eyes tell us we are close to the truth (for now it’s only an estimation), we lock the wheel in place and cut a right spacer.

Because we are going to use a drive side pulley rotor by RC Components (where pulley is also the rotor), we bolt it on the wheel, wrap the belt around the pulley, find the right tension of the belt, and lock the wheel in place. We measure the distance from the swingarm pivot to the center of the rear axle. Of course, distance must be the same for both sides (don’t rely on the position of the axle in right and left slot of the swingarm, because some frames can have these slots incorrectly machined and not the same size on both sides). On the left side, we measure the spacing to the pulley/rotor and from the pulley rotor to the wheel. We cut 2 spacers and install again the wheel with its brake drive system. (Later a custom pulley spacer will replace the spacer from pulley to wheel). We reinstall the wheel and pulley brake system, adjust again the belt tension, and measure again the distance from swingarm pivot to rear axle center, on right & left side. Our wheel seems centered. We check again running 2 steel plates on each side on the tire going forward. After being sure that these 2 plates run parallel, using vertical plates against the frame, we measure the distance to the frame, right and left side.

Since we had to mock up the rear of the bike to know the exact position of the wheel before fabricating the rear fender, we take advantage of this mock up to check if our pulley spacing is correct. We lift the rear of the bike with 2 4×4 pieces of wood under the frame, and give the wheel several rotations forward and backward. We observe the belt running on the pulley. It doesn’t want to go off the pulley. Of course, the belt (1 ½ inch) clears the tire on 1 side and the frame left side plate on the other side. Our wheel is perfectly in place. We lock tightly the wheel. (You don’t want it to move during the fabrication process, or be ready for bad surprises: tire too close or too far away from fender, fender not following curve of tire, etc…). Yes, it happens. Trust us again about this one. Now, we can start the rear fender fabrication.

Even when we build a solo seat bike, we make our rear fenders strong enough to carry a passenger. We are very understanding of our clients: we know that may leave alone, then need to ride back with a passenger…Anything wrong with fabricating a fender stronger that it should be for a solo rider. It’s the reason why all our fenders have internal struts. These struts are quite difficult to make for a pointed fender. As starting point, we want to use the slots in the frame where classic parallel struts are supposed to slide in.

But I immediately realize that a curve starting from this position will not follow perfectly the curve of the tire. So, I cut a piece of cardboard extending rearward the frame sideplate. Using a flexible steel rod, and using the tire as a reference, I draw a curve and cut the cardboard to know the extra piece we have to add to the frame side plates. From there, 2 thick rods will be welded and will join each other where I want the rear fender to end: 1 inch behind a vertical line going through the end of the swingarm.

No English wheel to fabricate this fender. No aftermarket fender to start from. Just 2 sheets (because this fender is going to be “double wall”) of 14 gauge steel hammered and hammered during half a day until Sean gets the shape I want.

Not only our fender is very thick, but also Sean reinforces it with 2 steel lips. “Boxed” this way, no chance the fender will ever vibrate or crack the paint. Sean, who was 195 pounds before hammering it, and 190 pounds after, is finally authorized to sit on it. As strong as stone can be. I joke that we are very safe because nobody with such a bike is going to go back home with a girl his weight.

Time for spraying cheap primer. Because as everybody knows: I hate rust.

Pet owners look like their favorite pets. I guess my bikes look like me. A projection of my personality (many sides, meaning many bikes), plus the client input. Expresso is a spec bike. So I can do what I want!

The motorcycle trend is toward FAT. Fat everything: tires, wheels, front ends and gas tanks. But I don’t like fat gas tanks. They make the bike look heavy and destroy the speed effect that everybody is looking for when stretching the bike. I love rear ends muscled by fat wheels & tires, but I think it looks better when the gas tank is slim and stretched to the extreme. Fuel capacity is not my main preoccupation either. So, we are going to fabricate a one-off gas tank narrow, with a lot of arch, stretched as much as we can.

At CHC, we custom make gas tanks in 3 & 5-inch stretch for cruisers and choppers. In the fabrication room, they are laid down upside down on a bench waiting for the last cosmetic welds before being shipped to our clients. Vision of steel seagulls! We pick one in 5 inch stretch and check on the bike to see how much stretch we can add: 1 inch.

Our extension is going to be a “dry” extension, meaning no gas will be in this part of the gas tank. It would be of no interest to make it a “wet” extension because no fuel valve can be installed at such a low place: the petcock would interfere with the rear rocker box!

A Hot Match pop up gas cap is welded and then we do a fast priming of the new gas tank

A 16-gauge piece of steel is folded around the lower part of our existing tank, and then formed around the frame top tube, and then tig welded.

Another 16-gauge sheet of steel is U shaped on the top tube to create a 1-piece bracket with a 4-point mount system. A cardboard template is used to match the curve of the bracket with the lower curve of the gas tank.

After checking the definitive position of the gas tank (I like to keep a big open space between the front of the gas tank and the frame neck), 2 holes are tapped on the top of the frame backbone and the bracket is bolted on. The bracket mounting holes are equipped with stock factory rubber grommets.

Most gas tanks look like an added piece on the frame. This is evident when you look at the gas tank from the front. We need to fill the gap between the 2 halves of the tank. A steel piece is cut to fill the gap, then curved and welded to the backbone.

A slight gap is kept between the plate and each side of the tank. Making it perfectly flush at this time would create big problems later when the bike is painted & cleared. Later, at molding time, a perfect fit will be done. Now our custom gas tank looks like it belongs to the bike.

It’s time to compare the bike in progress and the initial sketch. We are on our way…

Seat Pan

One thing I learned when I was head judge in the Rat’s Hole Show in Daytona and Sturgis is that a seat is often the weakest part of many very well built motorcycles. I am not talking about the color used or even the material employed. I am talking about the seat not fitting perfectly to the frame, not being symmetric or being afflicted with wrinkles because of poor seat pan preparation.

Some upholstery shops do seat pans. Others refuse and will do only the pure upholstery job. My opinion is that the bike builder should prepare a pan for a custom seat. A seat pan being “part” of the frame, it’s our responsibility to make it right. Steel pan or fiberglass? It’s very controversial. We do both and each has advantages and disadvantages. Steel pans require metal fabrication skills to make them fit perfectly to the rear fender. The pan must be very smooth when doing thin seats, like on most top custom motorcycles. If not, all imperfections, sooner or later, are going to push the foam (even high-density foam) and create weird wrinkles and crooked stitching lines. Fiberglass seat pans don’t require any particular skills and can be built by any builder working in his garage. Fiberglass can easily be smoothed out to create a perfect base and sanded for perfect adjustments. The danger is that fiberglass seat pans have a tendency to retract when curing (usually the first 48 hours), creating an imperfect fit to the rear fender (back of the seat pan retracting). But there are several ways to avoid or correct this problem. Because this story is about helping the largest number of non-professional builders, we decided to show a fiberglass seat pan fabrication.

To get started, buy 2 gallons of fiberglass at the closest auto store, find two paint brushes (no, you will not be able to reuse them) and a roll of foil. Cut a piece of thin cardboard for the sitting part. Cover it with foil and continue up the fender (no cardboard is used on the fender part of the seat because cardboard will never fit perfectly to a curved shape). Be generous with the foil, covering more than the seat area. Cut pieces of fiberglass cloth to imitate the shape of the seat. Then, using a brush, soak the fiberglass cloth with resin. Let it dry 24 hours. The day after, do a second coat of resin using extra hardener for fast curing. Wait 24 hours more. Then with a thin felt pen, you can draw your seat. To trace a perfect curve for the back seat, I use …my welding rod.

Remove the pan and give it its definitive shape by cutting it with a small cutting wheel. To be certain that the back seat has a perfect symmetry, we cut a piece of paper imitating the back seat. We fold it in half. Right away, we know where the cutting wheel has to work again against the fiberglass. Sand the top of the pan for a smooth finish.

To hold the seat in place, it’s very simple. The pan being installed on the frame, drill two holes in the front at the place where the front tube extends to the seat. Drill through the fiberglass. We drill only one hole through the fiberglass in the back fender. Then we fiberglass three button head bolts into the three holes. Your seat can now be dropped into place. It will never move while riding and it will not need any tool to be removed. Our seat pan fits like a glove.

Each step of the building process is important, but one of the most critical is the frame preparation before the paint job. At this stage, we must check that all parts are fitting together and make any brackets or holes in the frame. Because when the paint is dry, it’s too late to make any modifications. Or it’s going to be very, very costly.

First, we need to make two slots in front of the rear fender to be able to bolt and unbolt the custom oil tank.

I don’t intend to do extra fabrication on the front tubes to hide the voltage regulator. Because I don’t like regulators held on a bracket in front of the engine mount, I decide that it should be “buried” somewhere else.

The best hiding place is in front of the custom battery box that we fabricated. Because the box we made fit the dry cell battery very tightly, we cannot bolt the regulator from inside the box. So we weld a block of steel, tap two holes in it and bolt on the regulator from outside.

It means that we will have to route the regulator wiring through the left lower frame tube, up to the engine. For this, we drill two holes, one to enter in the frame, one near where the alternator will be plugged to the engine.

Usually I like rear brakes to be placed in a 12, 3, 6, or 9 PM position around the rotor. Because of the unusual shape of our swingarm, it seems that none of these positions works properly. The rear brake seems to “compete” visually with the flowing lines of the swingarm. After many tries, it seems to me that the 5 PM position is the best. The boys approve. So we custom make an anchor rod running parallel to the belt. A hole is tapped inside the swingarm to connect the brake to the frame.

For the rear brake line, a hole is made near the master cylinder with the line jumping to the left side through the frame cross section and back to the rear brake.

Because the bike will have no turn signals, only a headlight and my new L.E.D side mount tag with a run/brake light (picture of the 1st prototype), the electrical system is quite simple.

The ignition/kill switch will be on the left side incorporated in a coil bracket, and the bike will be started with a switch from Cycle Engineering installed directly on the starter.

It’s almost time to have the frame molded and prepared for paint. I review the frame in detail, writing all instructions directly on the frame: welds to be grinded, sections to be reworked with filler, shapes to be molded, etc…

For the first time in eight weeks, Expresso is going to leave the shop for a one-week beauty treatment.

Oz’s Garage Build

By Bandit |

|

I was sittin’ around listening to Bandit and Zebra go at each other again, over some b-s detail, and thinking’ that I’d probably be doin’ the world a favor to just blow both of them away, when it hit me. We’ve all read about the Bikernet West versus Bikernet East build up. We heard about how much trouble Zebra had getting his ride over to Eddie Trotta’s, and Bandit gettin’ the Blue Flame over to Joker machine for a little tweak. I couldn’t help but think, “What’s the guy do whose only got his garage and hand tools?” Whatta ya do when you’re snowed in up in Maine, or there isn’t a high line custom shop within a days ride? I started to get steamed, “Bikernet’s for the rider, dammit!” “We need to show our folks a way to build a cool lookin’ ride when they don’t live close to a famous custom builder.” “Yea, right,” said Zebra, “how’re you gonna manage that?” I jumped to my feet, threw my Pepsi can against the wall, watched it bounce off Snake’s head, and announced, “I can build a hot custom using nothing more than Harley-Davidson’s accessory catalog and my credit card!” Every eye in the garage shifted my way, quiet laid over the shop like a blanket, Bandit fixed me with a cool gaze, “You’re on.” “Oh, crap,” I thought, “now what?” Luckily, I had just made the deal of the century on a 2000 FXST.

That will be the starting point for what’ll be called Oz’s Garage Build-up. What we’ll attempt to do here is create a custom that anybody would be proud to ride and own, but we’ll do it as if we were living in some remote corner of the country. With no access to anything other than the H-D Accessories and Motor Parts Catalog and the main line shipping companies.

We’re going to build this thing completely in my garage, no mills, no paint shops, no welders, and see what we can come up with. Wish us luck, if I screw this up I may end up living in Maine!

|

|

Phase one is together and on the road, which is a minor miracle considering the near-flood conditions that have been plaguing us lately. You know, when I started this project, the premise was that we wanted to do a build-up that attempted to duplicate the plight of our brothers and sisters that didn’t live in the custom bike mecca of Southern California, and were forced, either by geography or weather, to do all their work in their garages. Little did I know, when I started, that the weather gods would provide SoCal with a first hand glimpse of what it was like to live in a less hospitable climate, and make my theoretical project into a real life experience. Yesterday was our first day of sunshine in a month, and, as soon as I saw it, I shoved the Softail out of the garage and hit the road for the shakedown run. It ran like a charm, then back to the garage for a few minor adjustments, and down the highway we went. I gotta tell you, I’ve got a new appreciation for you folks that live in rain and snow country, but now let’s get to the build-up. With this first phase we’ve concentrated on basic performance and appearance. We’ve all heard the old saw about “chrome won’t get you home,” but if you’re building a custom it’s hard to get around the fact that shiny stuff makes things look better.

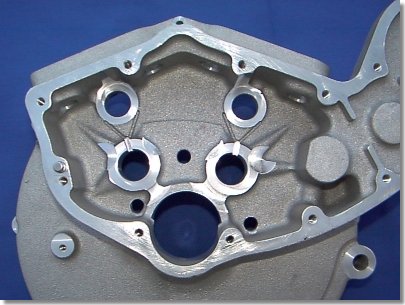

We replaced the inner and outer primaries, rocker boxes and cam cover and trans top and side covers. As you can see the quality is perfect, and, being from the Motor Company, the fit was exact.

As far as our initial performance work, we chose the 1450 Stage 1 kit. The kit includes the Screaming Eagle Holley Performance Induction kit, the SE 6200 RPM Ignition, and the SE-II Mufflers. We’re still waiting for the mufflers to arrive, but they’re due in the next few days. We’re planning on doing a more aggressive performance package in the future, so we chose to also install a Screaming Eagle clutch kit at this time.

|

|

We started with the primary first. This operation requires the most work so it made the most sense to begin here. One of the things that will dress up a ride in a hurry is a chrome inner and outer primary. Obviously, first you gotta get the old one off. Remove the outer primary, and the primary chain assembly, clutch and basket.

This is a little more trouble with a Softail since it’s necessary to remove the oil tank.

This is the only way to get the starter loose. Moving the starter out of the way will also help when installing the tranny top cover. Bolt the inner primary in place, following the torque pattern in your service manual, and re-assemble the primary drive.

|

Remember to remove the spacers at the rear of the clutch basket before installing the new clutch.

Always lube the plates and friction disks with Primary oil before inserting them into the clutch hub. Finish up with the rest of the drive, according to the manual.

Bolt the outer primary in place, also following the torque pattern, but after installing the tranny top cover and replacing the starter, and this side’s done.

The oil tank can now be replaced. We also went with H-D’s braided oil lines, they fit perfectly and looked very cool.

The cam cover, rocker boxes, and tappet covers go on next. These are very straightforward operations, and, as long as you’re careful and clean, you should have no problems.

We now installed the SE Holley kit.

This operation is covered in the Bikernet Garage section in detail, so we won’t go into a step-by-step here. Needless to say, the kit and instructions made this job a breeze. At this time, we changed out the ignition module and coil, also covered in the Garage section.

We wanted to lower this ride so we installed H-D’s Low Profile Rear Suspension. This operation, too, is detailed in the Bikernet Garage.

As we told you at the beginning of this story we took the Softail out and put it through its paces. The Holley performed flawlessly and the bike ran hard.

When we got home we rolled it out to take a few shots so that you all could see the before and after. Low, fast and pretty. I’d say that’s a pretty good start.

Now let’s ride. Oz

May 31, 2001 Part 2

By Bandit |

Continued from Page 1

BROTHER ATTENDED MEMORIAL DAY CELEBRATION IN ARLINGTON– I was fortunate enough to be able to observe the laying of the wreath at the National Memorial Cemetery in Arlington, Va., on Memorial Day, and I’ll tell all of you that there were not too many dry eyes in the crowd (including mine). It was a great day for me. After coming home and reading this, I knew I had to share it with all my friends.

Friend and Shipmate,

Dan

TAPS– We have all heard the haunting song, “Taps.” It’s the song that gives us that lump in our throats and usually creates tears in our eyes. But, do you know the story behind the song? If not, I think you will be pleased to find out about its humble beginnings.

Reportedly, it all began in 1862 during the Civil War, when Union Army Captain Robert Ellicombe was with his men near Harrison’s Landing in Virginia. The Confederate Army was on the other side of the narrow strip of land. During the night, Capt. Ellicombe heard the moans of a soldier who lay severely wounded on the field. Not knowing if it was a Union or Confederate soldier, the captain decided to risk his life and bring the stricken man back for medical attention. Crawling on his stomach through the gunfire, the captain reached the stricken soldier and began pulling him toward his encampment. When the captain finally reached his own lines, he discovered it was actually a Confederate soldier, but the soldier was dead. The captain lit a lantern and suddenly caught his breath and went numb with shock. In the dim light, he saw the face of the soldier. It was his own son. The boy had been studying music in the South when the war broke out. Without telling his father, the boy enlisted in the Confederate Army. The following morning, heartbroken, the father asked permission of his superiors to give his son a full military burial despite his enemy status.

His request was only partially granted. The captain had asked if he could have a group of Army band members play a funeral dirge for his son at the funeral. The request was turned down since the soldier was a Confederate. But, out of respect for the father, they did say they could give him only one musician. The captain chose a bugler. He asked the bugler to play a series of musical notes he had found on a piece of paper in the pocket of the dead youth’s uniform. This wish was granted. The haunting melody we now know as “Taps”, used at military funerals, wasborn.

BROS CLUBS JOINS BIKERNET– We now have roadside service and insurance programs at your fingertips on Bikernet. I’m in the process of having all my insurance re-quoted from Bros Club. If they do a better job, they’ll have all my business.

Regarding the roadside service, check it out. We all break down from time to time or need some help. AAA will not pick up bikes and I’ve been a member for 20 years, so fuck them.

HARLEY-DAVIDSON SUPPORTS VIETNAM VETERAN INITIATIVES WITH $100,000 DONATION–Harley-Davidson Motor Co. announced support of two Vietnam veteran initiatives with a $100,000 donation made at the culmination of the Rolling Thunder XIV motorcycle rally in Washington, D.C., on Sunday.

A $50,000 contribution was made to the American Battle Monuments Commission to help fund a congressionally authorized memorial plaque at the Vietnam Veterans Memorial in Washington, D.C., honoring veterans who died after their service in the Vietnam War, but as a direct result of that service.

Another $50,000 contribution was made to the Vietnam Veterans Memorial Fund to help support the Traveling Wall, a half-scale replica of the Vietnam Veterans Memorial and The Wall That Heals, Traveling Museum and Information Center, which visits communities throughout the U.S.

“On behalf of Harley-Davidson and our many employees, dealers and customers, we are proud to support these noble efforts honoring the service of Vietnam veterans,” said Jim McCaslin, president of Harley-Davidson Motor Co.

Harley-Davidson has a long history as a U.S. military supplier. The company’s motorcycles were first used for dispatching and scouting during border skirmishes on the Mexican frontier in 1916. During the first year of U.S. military involvement in World War I, approximately half of all the company’s motorcycle production went to the military. During World War II, Harley-Davidson produced approximately 90,000 military motorcycles.

More than 14 percent of Harley-Davidson’s U.S. employees are veterans of the U.S. military, and many of Harley-Davidson’s dealers and customers have also served.

Harley-Davidson salutes the nation’s veterans every year on Veteran’s Day, Nov. 11, by hosting special events at its Kansas City, Milwaukee, and York, Pa., facilities.

HORSEPOWER REPORT FROM AUSTRALIA–Sent you a couple of e-mails in the past. Heaven sent ’47 Knuckle, 200 tyrein a stock Twin Cam swingarm, 12.9s from an ’88 Twin Cam for $1,000, etc.Live in a place called Alligator Creek, Queensland, Australia. It is around15 miles from Mackay, Queensland. This district has the largest number ofHarleys per capita. Only 100,000 people in the district and the localHarley shop, Mackay Motorcycles, has sold over 500 Harleys.

The dyno belongs to Steve Gay, Cylinder Head Development, phone 0749521611. It is a 1200 hp 1200lb ft Baker Bros engine dyno with D Pak dataaquisition gear. The shop normally does drag race engines for cars andoffshore marine racing engines. The bike owner had his car engine built atthe shop and was so impressed he asked them to do his new twin cam heads.The story was published in issue 224 of Oz Bike. Second part of the storywas never published when the bike went 12.0’s with a 95 kit, ported stockvalve original TC heads, Zippers red shift cam but still with the standardCV carb. For Stage 3, the twin cam has since been fitted with big Manleyintake valves, ported extensively, fitted with a home made webber set upand is now making 133 hp at 6300 rpm and 125 lb ft at 4800 rpm. Beforebeing dynoed it ran 11.66 at 114.5 mph with the webber so far out of tunethat it turned a brand new set of plugs dark brown in one run and cut outcoming down the return road. It was making around 110 hp at the back wheel.

The twin cam owner, Gavin Cass, was aware of my computer modellingprograms. He asked what I could do regarding the Harley. Gave him a recipefor 137 hp at 6500 rpm. Told him the size of the valves needed, the airflowat .500″ lift, the cam specs, the compression, etc. required. To dyno theengine, Gavin used a chev bellhousing and adaptor plate to mount to Steve’sstrainer. Inside the bellhousing is a custom made flywheel with a clutchplate and ring gear.

In nearly all cases where one of my computer matched combos is duplicatedmore horsepower than predicted is found. Eg a 480 hp recipe makes 505hp.By rights if the program predicts 137 hp, would expect 140 hp to beachievable. The computer doesn’t know what brand is on the tappet cover orif the motors a single cylinder or V12. If you put accurate info in, itspits out reliable details to build by. Let me know when you want a choosea cam that’s perfect for your bike?

–Bob “Secret Squirrel” Kotmel

Biker horseshoes–must piss off the ladies

HOLLISTER REPORT– More than just the weekend! Bolado Park will be open Fourthof July. Go to

FACTS FROM THE BIKERNET ARCHIVES OF HIGHER LEARNING– Many years ago in England, pub frequenters had awhistle baked into the rim or handle of their ceramic cups. When theyneeded a refill, they used the whistle to get some service. “Wet your whistle,” is the phraseinspired by this practice.

–Jerry Heller

SHOVELHEAD SAVES MAN’S LIFE–Read the story “Return” by Jim Hubbard and find out how one motorcycle pulled this brother back together.

ULTRA MOTORCYCLE COMPANY FILES CHAPTER 11– Ultra filed a petition for relief under Chapter 11 bankruptcyon May 21, 2001. The filing was necessitated by the threat of a foreclosuresale scheduled later that day by the company’s secured creditor. UMC statesit is continuing all normal business operations and will continueuninterrupted services to its dealers and customers….

JULY 9 IS GUN BURNING DAY AT UN–It is “Small Arms Destruction Day” on July 9, 2001. Plans are underway for government agents to ignite huge bonfires of handguns, rifles and other firearms in major population centers worldwide.

No joke. The United Nations Conference on Small Weapons is sponsoring massive gun burnings on July 9 to mark the openingin New York of the UN Conference on Illicit Trade in Small Arms and Light Weapons. Organizers of the conference say “thepublic destruction of weapons” is good because it “is one of the best ways to attract attention” to global civilian disarmament.

Whose guns will be burned? Privately held weapons that have been captured or confiscated by governments, of course. But certainly not the guns held by governments and their armies, police forces and death squads.

BIKERNET CARIBBEAN REPORT–Hey, another week goes by and it’s still raining down in the Caribbean. Summershowers are a bitch, but they will plenish our water supply for thecoming months.Funny how things are, I’m reading the 30th anniversary EasyRiders and happento see a photo of a chopper, so happens we own that litlle chopper, with afew changes that we have done in the past years, but the same bike. Webought it from a trade in that Bourget’s got a few years ago. Nice oldschool chopper, in the magazine it was called Fatal Attraction. I checkedmy old magazines and found the whole shoot for it, so I went and took somephotos, here they are.

The annual Jack Daniels BBQ competition will take place the 24th of June,in Parque Luis Mu?oz Marin, as for the past six years this will be an eventthat all bike riders participate in. Give us a call at the shop if youhappen to be arounf PR or just for info.

Next weekend the HOG South ride will take place. It’s an overnight rideinto the mountains and then to the southern town of Ponce for the party. Sunday we ride back to San Juan.

Talked to my buddy, Mike Maldonado, he’s back and stronger than ever, evenhas his own Web site www.heavycyclecustoms.com, its still under constructionbut some photos of his super cool bikes are already there.

Plans are already rolling for the next Caribbean Rally, in November. Therally starts on a Thursday and it’s over by Saturday night. Caribbean CustomCycles and Harley-Davidson of San Juan (Motorsport) are planning to do theFirst Caribbean Bike Show Sunday, all day…. Any info e-mail us.

Oh well,,,,,, back to work, get some progress on the choppers and get thattrailer ready for Sturgis……Take care.

–Jose

A mechanic was removing a cylinder head from the motor of a Harley when hespotted a world-famous heart surgeon in his shop.The heart surgeon was waiting for the service manager to come take a lookat his bike.The mechanic shouted across the garage, “Hey doc, can I ask you a question?”

The famous surgeon, a bit surprised, walked over to the mechanicworking on the motorcycle.The mechanic straightened up, wiped his hands on a rag and asked, “So doc,look at this engine. I also can open hearts, take valves out, fix ’em, putin new parts and when I finish this will work just like a new one.So how come I get a pittance and you get the really big money, when you andI are doing basically the same work?”

The surgeon paused, smiled and leaned over, and whispered to themechanic….. “Try doing it with the engine running!”

MIKE LICHTER PHOTO EXHIBITION IN STURGIS–The Journey Museum in Rapid City, S.D., will host a photography exhibition by Michael Lichter titled “Biker Generation.” The images, which include many of Michael’s best-known works from 20 years of photographing the biker lifestyle, will be on display from Aug. 4 through Sept. 3, 2001. Thirteen of the finest custom motorcycles by some of the most famous bike builders in the world will be on display with the photographs in the gallery as well as in the museum atrium from Aug. 4-11, 2001.

An opening reception with Michael Lichter and most of the participating builders is scheduled for Aug. 7 from 4 p.m. to 8 p.m. The builders include Mitch Bergeron, Jesse James, Fred Kodlin, Billy Lane, Bob McKay, Jim Nasi, Arlen Ness, Cory Ness, Ron Simms, Donnie Smith, Russ Tom, Eddie Trotta and Paul Yaffe. This reception will be free and open to the public.”Biker Generation” is timed to coincide with the 61st annual Bike Week in Sturgis during which more than 500,000 bikers congregate in the Black Hills. This is The Journey Museum’s first exhibition with a motorcycle theme. Given that motorcycling is integrally tied with the history of the Black Hills and that the Journey’s mission states that the museum will “serve as a forum to preserve and explore the heritage of the cultures of the Black Hills region,” the show was considered a perfect fit.

The Journey Museum is open from 9 a.m. to 5 p.m. daily; Aug. 4-11, the museum will remain open until 6 p.m. The museum is located at 222 New York St., two blocks east of the Rushmore Plaza Holiday Inn and the Civic Center where Harley-Davidson is headquartered. The normal museum admission of $6 has been reduced to $5 (kids 10 and under are free) during Bike Week; it includes admission to the entire museum and this special exhibition.

A WIFE AND HER HUSBAND– were having a dinner party for all the highsociety people in town. To show how classy they were, she decided atthe very last minute that snails should be served, but all the storeswere closed. So, she asked her husband to run down to the beach withthe bucket she was handing him to gather some snails. Very grudginglyhe agreed. He took the bucket, walked out the door, down the steps,and out to the beach. As he was collecting the snails, he noticed abeautiful woman strolling alongside the water just a little furtherdown the beach. He kept thinking to himself, “Wouldn’t it be great ifshe would come down and talk to me.”

He went back to gathering the snails. All of a sudden he looked up,and the beautiful woman was standing right over him. They got totalking, and she invited him back to her apartment a little ways downthe beach. When they got there, they started fooling around. It gotso hot and heavy that he was exhausted afterwards and passed out.

At 6:30 the next morning, he woke up and yelled, “Oh my gosh! Mywife’s dinner party! She’ll kill me!!” He gathered all his clothes,put them on real fast, grabbed his bucket of snails and ran out thedoor.

He ran down the beach all the way to his apartment. As he startedrunning up the stairs, he dropped the bucket of snails. Snails wentflying and were all over the stairs. Just then the door opened andhis angry wife was standing there wondering where he’d been allthis time.

He looked at the snails scattered on the steps, then looked at her,then back at the snails and said, “Come on little guys, we’re almostthere!”Las Vegas sign

JIMS NATIONAL DUE TO ROCK LAS VEGAS–The dates for the races are Oct. 19-21. Hordes of bikers will be riding out from Los Angeles to the meet. Racers from all over the country will be competing. From all accounts, it’s a first class event. We’ll keep you posted as we get closer.

THE SMOKEY MOUNTAIN SMOKE-OUT– is planned for July 13-15 inCherokee, N.C. Yes, that is Friday the 13th – so break out the green Krylonpaint, spray your choppa and head out.

The Horse staff will be having dinner at the Harrah’s Cherokee Casinoall-you-eat buffet at 7 p.m. Friday. There is special “motorcycleonly” parking in front of the casino so that we don’t have to walk a longway, like the less fortunate, little people who don’t ride a chopper. GOTO THE BUS ENTRANCE where THE HORSE will have a table set up to give HORSEreaders a break on dinner and some gambling tokens. Check –Edge I’M OUTTA HERE–The Buell is in pieces in preparation for the run to Sturgis. We’ve stripped off some of the linkage and headlight brackets for chroming. We may end up taking the tripe-trees off for plating or powder. We have an assortment of Joker Machine accessories ready to install. Phil Stadden is already working on the plastic-metal paint and we’re arguing over the color scheme. The Buell makes it easy to look forward to the ride. Goddamnit, it’s already June and half the year is gone. Hang on, it only speeds up from here.As of tomorrow, some time everyday will be dedicated to writing my next book, that is, unless a woman gets in the way. Let’s ride–Bandit

May 31, 2001 Part 1

By Bandit |

As I pulled onto the Harbor Freeway, the traffic was light. I had nowhere to knock wood, so I kicked it up to 80 mph and settled into the diamond lane. From there I got on the 91 and began the blitz to the edge of town, which is almost at the Arizona border now. At about 75 miles I spotted my Van Buren turn-off. I hadn’t hit a lick of traffic. A holiday weekend without myriad drunken accidents? I couldn’t believe it. From there it was a series of rambling roads and highways to Idllywild — Van Buren to the 215, to Ramona Expressway, to 74 to 243 to Jack Daniels. There was a sliver of a moon slicing the pitch black night as I pulled up in front of their gate.All day Saturday we chainsawed everything in sight. We danced the dangerous dance of dodging creaking timbers that would have broke both my legs in a heartbeat if it had shifted the wrong way. With NuttBoy’s wife, Debbie, doin’ the jig on the creaking log with drinks and munchies, we cut from dawn to dusk and finally cut that sonuvabitch from stem to stern. I kept thinking of the movie “A Great Notion.” The next morning I rode back, stiff and sore. I needed the touch of a woman and the smell of salt air to relieve lungs full of 2-stroke fuel. Let’s get to the news:

THE AMA IS ABOUT TO ANNOUNCE ITS NEW HALL OF FAME LINEUP– The AMA is adding to the list of legendary figures in its Motorcycle Hall of Fame. The 28 new inductees include racers, tuners, engineers and media figures. The Motorcycle Hall of Fame recognizes individuals who have made significant contributions to all aspects of motorcycling. Check the Web site for the results, and join ’em or join the local motorcycle rights group. We need to keep these organizations strong.

GUY WALKED INTO THE CORNER STORE– with a shotgun and demanded allthe cash from the cash drawer. After the cashier put the cash in a bag,the robber saw a bottle of scotch that he wanted behind the counter ontheshelf. He told the cashier to put it in the bag as well, but he refusedand said, “Because I don’t believe you are over 21.”

The robbersaidhe was, but the clerk still refused to give it to him because hedidn’tbelieve him. At this point the robber took his driver’s license out of his wallet and gave it to the clerk. Theclerk looked it over, and agreed that the man was in fact over 21 and he putthe scotch in the bag.

The robber then ran from the store with his loot.The cashier promptly called the police and gave the name and address of therobber that he’d gotten off the license. They arrested the robber twohourslater.

CHROME SPECIALTIES PANHEAD ENGINE–That’s right, Chrome Specialties and Keith Ruxton are building a series of performance Panheads. Next week we’ll speak to Keith upon his return from his vacation and get all the particulars. Watch for it, or if you need one ASAP, check the Chrome Specialties Web Site Here.

INDIAN TO CELEBRATE 100 YEARS–ALMOST–This is a tough one. Indian will commemorate the brand?s 100th anniversary with a cross-country ride June 16 – July 4, 2001. The 5300-mile ride will begin in Springfield, Mass., where the original Indian Motocycle factory stood and will visit various Indian Motorcycle dealerships across the U.S. en route home to Gilroy, Calif., where the current factory is located.

The problem is that finding an Indian from 1955 until now is tough. Even the current bikes are not Indians per se, but they’re trying.

HELEN ORDERS DSL–Helen is our main drag racing correspondent and photographer. Watch our drag racing page, it’s coming alive.

“I ordered DSL today. Mailman thought it was a good idea to free up the phone line and have the high speed access.??So it’ll be ready about the time I leave for Denver. Hopefully Garrett (my kid) will have the bugs worked out of it by the time I return home.?? The modem is an Intel USB external with no extra power cord to worry about. Got it for free and it is totally plug and play.

I don’t figure I’ll spend any less time behind this monitor, but I’ll get a lot more accomplished while I’m here. And of course I can send erroneous e-mails at the speed of light to the wrong people.

Oz told me today that I needed DSL to speed my ass up. Suppose I’ll look into it–Bandit

Holy shit….. did you two blow the dust off the candles you use to light and heat your homes while you were at it?–Digital

A FELLOW– was invited to the home of some old friends for dinner. His buddypreceded every request to his wife by endearing terms, calling her Honey, MyLove, Darling, Sweetheart, Pumpkin, etc.

The guest was impressed since the couple had been married almost 70 years,and while the wife was off in the kitchen he said to his friend, “I thinkit’s wonderful that after all the years you’ve been married, you still callyour wife those pet names.”

His buddy hung his head. “To tell you the truth, I forgot her name about tenyears ago.”

–Helen Wolfe

ALL-NEW PATENTED CHALLENGER BAFFLE FROM SAMSON– Samson has developed a new performance exhaust system called Challenger, which has a patented baffle. The baffle is a unique reverse cone that forms a nozzle to create velocity while drawing exhaust away from the head.

The notion came to Kenny Price, president and founder of Samson Exhaust, in the middle of the night, while two naked women jumped up and down on his heart-shaped bed, shouting, “Mr. Samson hired us. We want Mr. Samson.? Oblivious to their shrieks, Kenny was well aware that velocity creates torque, so he tried the reverse cone. The holes in the cone allow gases to evacuate. The system also allows the owner to adjust for sound. “The second baffle can be removed, but the real magic is in the reverse cone,” Kenny said.

“We wanted to create a gradually shaped outer cone,” Kennysaid, describing the exterior of the new muffler. “Some manufacturersof tubing said that it wasn’t possible, but we created a hybrid conewith a gradual taper to conceal the muffler appearance.” The diameterof the pipe increases only 1 inch in the 24-inch-long muffler.”It’s a subtle cone,” Kenny explained.

Kenny is manufacturing complete systems that incorporate theChallenger muffler to fit Softails, Dynas and Sportsters for Twin Cam and Evolution models.

Samson bolted this revolutionary system to a stock Twin Cam andlet ‘er rip. “With an out-of-the-box model, we baselined the bike at50 horses. With our system in place, including reversion cones, weexperienced 57 horsepower and an additional 10 pounds of torqueconsistently.” The system comes with the torque cones, full coverageheat shields and all the mounting hardware. “Plus our pipes aredesigned to fit perfectly,” Kenny said.

Installation of the complete exhaust system ($499) is a breeze. For more information, check out the Samson Web site through Bikernet.com.

On to Page 2

May 24, 2001 Part 3

By Bandit |

Continued from Page 2

COAST TO COAST BIKER NEWS–Compiled and Edited by BILL BISH,National Coalition of Motorcyclists

NCOM CONVENTION “JUST KEEPS GETTING BETTER!” As NCOM Chairman DocReichenbach was making last-minute preparations for the 16th Annual NCOMConvention in Orlando, Fla., May 10-12, 2001, he told Bill Bish, NCOMexecutive director, that ”I just want everyone to say that this was the bestconvention ever!”By the time the National Coalition of Motorcyclists’ Convention wounddown to the Silver Spoke awards banquet on Saturday night, it was clear tothe nearly 1,100 conventioneers that this really was the best one ever!But, as Bish pointed out during his keynote speech at the banquet, ”Thefunny thing is, that’s what we hear every year!”Aside from the record attendance, full agenda and thought-provokingseminars, one of the things that made this year’s convention special was thatwe got to help ABATE of Florida and the Confederations of Clubs of Florida,our convention hosts, celebrate their newly won freedom of choice on helmets!”Celebrate Freedom” was the theme for the convention, and Florida nowmakes the fifth state to repeal its adult helmet law in the fiveyears since bikers from across the country worked together to repeal thefederal helmet law mandates.Next year’s NCOM convention will be held at the Downtown Radisson in NewOrleans, La., May 9-11, 2002. Call NCOM at (800) 525-5355 for moredetails.

HEALTH CARE DISCRIMINATION AGAINST MOTORCYCLISTS LEGALIZED. In one of hisfirst official acts as new secretary of health and human services underPresident George W. Bush, former Wisconsin Gov. Tommy Thompson, anavid motorcyclist himself, revealed that after personally reviewing theinterim final rules for nondiscrimination in health care coverage, his officecannot find legal justification to modify or disallow the new regulations.

In effect, this revelation revokes the efforts of multitudes ofmotorcyclists who successfully lobbied Congress in 1996 to guarantee accessto medical benefits for employees injured in motorcycle accidents. The newrules, which went into effect May 8, 2001, basically say that motorcycleriders and participants in other recreational activities cannot be excludedfrom health care coverage, but benefits can be denied if the employee isinjured while participating in those activities.

SUPREME COURT ALLOWS ARREST FOR TRAFFIC OFFENSE. A divided U.S. SupremeCourt ruled on April 24, 2001, that police may arrest individualsfor minor traffic violations or other misdemeanor offenses normallypunishable only by a fine, such as unbuckled seat belts or public littering.By a 5-4 vote, the high court declared that the Fourth Amendment, whichbans unreasonable arrests and searches, does not prevent police from makingsuch arrests without a warrant. TEXAS POLITICIAN DONS LEATHERS FOR BIKERS’ RIGHTS. El Paso StateRepresentative Norma Ch?vez wore a black leather vest with ”LegislativeWarrior” embroidered on the back when she passed legislation to enhance therights of motorcyclists on April 20, 2001.As she introduced the bill on the House floor, she pulled her hair backto help give her a ”biker look,” according to the Capitol Notebook writtenby Gary Scharrer in the El Paso Times.

”That is tough!” House Higher Education Chairwoman Irma Rangel,D-Kingsville, said in assessing Ch?vez’s motorcycle look.Ch?vez’s bill breezed to passage without discussion and without a single”no” vote. Part of it is intended to stop police harassment ofmotorcyclists who don’t wear helmets. Only motorcyclists younger than 21 arerequired to wear helmets. Ch?vez’s bill allows police to stop helmet-lessmotorcyclists only if they appear younger than 21, and they cannot stop arider to check if their helmet meets DOT specifications.

ARIZONA ENACTS PRO-MOTORCYCLE LEGISLATION. ”As our Arizona lobbying teamwaited in the gallery for our bill to come up, it became apparent that thebills we were listening to had significant social impact and that ours wasimportant enough to have made it this far,” recalls Roger ”Priest” Hurm ofthe day their motorcycle safety bill passed the House and was eventuallysigned into law by Governor Hull, allocating $1 per motorcycle registrationto be spent on programs that benefit motorcycle riders.When SB1037 was called for vote and the green lights started showing upon the big board, with only six red lights, we knew we had a winner,”continued Priest, who is chairman of the MMA of Arizona and member of theboard of the National Coalition of Motorcyclists.

HERE’S ANOTHER UPCOMING HORSE COVERGIRL– Thought you needed a break. Watch for the issue of “Only the lonely” Choppers and down home freaks to hit your newsstand shortly.

ISLE OF MAN MOTORCYCLE RACES CANCELED OVER LIVESTOCK DISEASE The Isle ofMan TT motorcycle races became the latest sporting event to fall victim toBritain’s foot-and-mouth epidemic, as the island’s ministers have called offthe world-famous races for the first time since wartime because of fears that40,000 visiting race fans could spread the livestock infection.

The Isle of Man has so far remained free of the disease that has affectedmore than 1,450 farms in mainland Britain. The TT races attract hugeinternational interest, partly because of the danger of the two-week race. Since 1907, almost 200 riders have died on the island’s perilous 37-mile”Mountain Circuit.”

QUOTE OF THE DAY– ”We were free until we stopped fighting, now no onehas freedom. Chief Tawonka”–Inscription on Cigar Store wooden Indian

Mark Your Calendars…July 21, 12 p.m. to 8 p.m. and July 22, 10 a.m. to 5 p.m.at theLong Beach Queen Mary

TheL. A. Calendar Motocycle ShowBikes, bikers, babes, vendor booths, free stuff and funSaturday, 9 p.m.

Bikernet sponsored partyin the Observation Room barLive band, prizes, fun

HOT BIKE IN THE NEWS–Check out the July issue of Hot Bike. Mainly the cover. Bitchin M2 and even more better is the lady in “Blue.” Don’t care for the rear tire setup the guy did at all! The Airtech body work has been around since ’97 or so. Has the Buell carbon fiber chin fairing.

Like the Showa front forks with the dual disk setup. I can tell from the pic. the swing arm recall has not been done. Also the header pipe has the small 2″ Dia. collector. This was stock on the 95/96 S2’s. Not a good one for big H.P. Check out page 43 (Big HP Buyers Guide) At the bottom is Rivera’s Fatso motor. Twin Camcylinders and heads on a Evo single cam set of cases. This engine would look great in a RigidChopper. I really like the whole concept of this setup. No fucken cam timing chains. No base or rocker box gaskets problems. Very cool!!

— Paul

VIAGRA INGREDIENTS RELEASED–

3% vitamin E

2% aspirin

2% ibuprofen

1% vitamin C

92% Fix-a-Flat

HEY BANDIT–Thought you might want to see what we had made to welcome you at H-D of Charlotte. Aren’t you impressed? By the way, that’s M & M holding the banner. French Fry is our official shop photographer. You’ll understand why we call her F.F. when you see her.

Boy, do you have a lot of Southern stuff to learn while you’re here. You’ll be especially interested in the “mud” we asked you about before. Paul (your cub reporter) said he had already asked you about mud for your turtle. You better pay attention to this stuff.

–See ya!M & M

Hittin’ Da Garage–It’s Miller time at the headquarters and we’re going to bolt NuttBoy’s Pro Street together and roll it off the lift, so I can get the Buell in place for some maintenance, then a tear-down for Sturgis preparations.

Before it reaches happy hour and the girls get off work, I hope to cut a dusty trail. When it comes to women, I’m a chicken-shit. Remember “Three Redheads in a Swimming Pool,” a story I wrote a couple years ago? Well, I feel deja vu coming on.

Let’s Ride–Bandit

May 24, 2001 Part 2

By Bandit |

Continued from Page 1

RESCUE MOTORCYCLE SAFETY FOLLOWING NHTSA/NBC NEWS ATTACK!– The joint Motorcycle Riders Foundation/State Motorcyclists? Rights Organization (SMRO) campaign to advance motorcycle safety through the 107th Congress hit full steam last week, only to suffer damage when a torpedo hit was leveled by the National Highway Traffic Safety Administration (NHTSA) and ?NBC Nightly News with Tom Brokaw.?You may have missed the broadcast that millions watched, so here are the details and an urgent call to action.

On Thursday, May 17, ABATE of Colorado became the ninth SMRO to visit Washington, D.C., in concert with MRF, to advance, among other initiatives, a meaningful, no-strings resource injection to help eradicate the waiting period for safety training for all riders. The motorcycle safety component of the joint MRF-SMRO agenda calls also for the first-ever national campaign of Motorist Awareness of Motorcycles to wake up clueless motorists who continue to be at fault for most serious accidents involving cars and bikes.

Colorado?s intervention on Capitol Hill came at a pivotal time and brought the total to nearly 100 members of Congress who?ve heard our pro-safety/pro-freedom message.

Thursday evening, as your brothers and sisters returned to Colorado after a job well done, NHTSA and NBC News launched an agenda of their own: mandatory training and, of course, a bid for more and more research.

Not content with lobbying state legislatures to restrict motorcyclists? freedom, NHTSA came to the aid of NBC News last week to point out that there has been an increase in fatalities among older riders. Armed with what NHTSA later confessed to an MRF member as ?a power point presentation? based on ?raw data,? NBC News took aim at all motorcyclists and wrote a prescription for disaster: mandatory training for older riders and a scare campaign aimed at large motorcycles.And how did NBC balance the May 17th piece against the call for new mandates? By talking to dealers and riders who speak only for themselves and rely on best guess and anecdote. Had NBC bothered to talk to national advocates of motorcyclists? rights and safety, the network would have learned the truth:

The call to action:YOUR SAFETY IS ON THE LINE! CONGRESSMEN AND SENATORS WATCH NBC NEWS AND THEY ARE JUST AS LIKELY AS OTHER AMERICANS TO TAKE NHTSA-SPUN RAW DATA AS GOSPEL — UNLESS YOU ACT NOW.

1. Write to your congressman and U.S. senators and object to NHTSA lobbying the media about the dangers of motorcycling with ?raw data.? You can find email addresses for your members of Congress by entering http://thomas.loc.gov/ on your browser. You can also telephone your congressman and senators by calling the U.S. Capitol Switchboard at 202-224-3121. Phone calls are preferred.

2. Explain to your senators and congressman that the key to safety is the joint MRF/SMRO agenda: a resource injection to the states to satisfy the overwhelming need for voluntary training of motorcyclists — and the training of car and truck drivers with the first-ever national program of Motorist Awareness of Motorcycles.

3. Pick up the TELEPHONE and CALL the STATION MANAGER of your LOCAL NBC TELEVISION AFFILIATE. You can find the number of your local NBC affiliate under ?television stations? in your local Yellow Pages.

NEW SONNY BARGER BOOK PROJECT–Do you (or a friend or family member) have a thrilling or amusing biker story to share?

Sonny is writing his second book with the same co-authors as “Hell’s Angel” and it will include tales and adventures of other riders — club members and independents, celebrities and unknowns, bike builders, riders and fanatics, all the colorful characters that make up the biker lifestyle and culture.

Tell us your story by e-mail (200 words or less, please) before June 15. Be sure to include your name and phone number, so we can contact those with the best stories. In the book, names and events may be changed to protect the innocent and the guilty.

Help us show the rest of the world what “Ridin’ High, Livin’ Free” is all about.

Reply to this message or send to story@sonnybarger.com.

TROUBLE IN PARADISE OR MYRTLE BEACH–While Myrtle Beach was in full swing, our East Coast correspondent was delivering the new and photographed such as above to Bikernet. Now this:If you disliked the closing of Ocean Boulevard northbound as much as I did,here is the e-mail address of Myrtle Beach City Manager ThomasLeath. He is the man who made this decision and said on TV that hehadn’t received any negative comments about it. I have already sent hima letter and hope each of you will as well and pass his name and addressto anyone who would care to complain.

Thomas Leath

tleath@cityofmyrtlebeach.com

–Debbie Swain/Rogue

RUMORS FROM MILWAUKEE– Some news passed on to me. Second hand but the source is good. Buell is testing an overhead cam air cooled engine M/C at the testing grounds in Yucca, Ariz. The rear shock is said to be in a more coventional position, more like the way the Buell Blast rear shock is mounted.

It was said that the motor is much faster. Harley is working closely with Ford and Cosworth. Don’t know if this engine design is directly from that combined effort or not.

Rumor was that 2002 models were to have a new engine. It may be 002 or 003, don’t know for sure. The new models will be shown at the dealer meeting in July /Aug. I guess time will tell.

–Mystery Man

TRUE STORY–While standing in line, waiting to give hisnote to the teller, he began to worry that someone had seen him writethenote and might call the police before he reached the teller window.Sohe left the Bank of America and crossed the street to Wells Fargo.

After waiting a few minutes in line, he handed his note to the Wells Fargo teller. She read it and, surmising from his spelling errors thathe wasn’t the brightest light in the harbor, told him that she could not accept his stickup note because it was written on a Bank of America deposit slip and that he would either have to fill out a Wells Fargo deposit slip or go back to Bank of America.

Looking somewhatdefeated, the man said “OK” and left. He was arrested a few minutes later, as he was waiting in line back at Bank of America.

GAINS MADE AT ROAD ATLANTA AS REBUILDING SEASON PROGRESSES–Picotte Posts VR 1000’s Best Ever Finish at Road Atlanta; Smith Gets Up to Speed

BRASELTON, Ga. (May 21, 2001) – Racing in damp to drying conditions, Pascal Picotte gave Harley-Davidson’s VR 1000 its best ever finish at Road Atlanta with a 7th place on Saturday during the AMA Superbike doubleheader weekend. Teammate Mike Smith, who finished 12th Saturday after experiencing tire problems, nearly equaled Picotte’s mark in dry conditions Sunday, running competitive lap times and racing for 8th before crashing just before the final lap. Picotte suffered a mechanical failure on Sunday and did not finish.

“Although the second race didn’t turn out the way we would have liked, the weekend was another step in the right direction,” said Harley-Davidson’s Director of Racing John Baker. “A lot of development work is in progress and this weekend was about achieving specific improvements in suspension and handling. With an integrated effort the race team and engineering were able to achieve this result.”

Also over the weekend, Harley-Davidson VR 1000 privateer Jordan Szoke finished 13th on Saturday and 11th on Sunday racing for the Austin-Bleu Bayou H-D team.

The Harley-Davidson VR 1000 team will test at Road America in Elkhart Lake, Wis., this week and compete again June 8-10, when the AMA Superbike tour heads to Road America for another double-header weekend.

ANTIQUE OF THE DAY IN THE CANTINA–Besides the babe of the day, the Cantina is graced with an antique of the day and a contact for buying antique bikes. We hope to have one hot antique deal weekly in the Cantina. Give it a shot. It’s growing like crazy. “I rode my 50EL over to the Dutchess Col Fairgrounds in Rhinebeck, N.Y.,yesterday for an antique show and swap meet.Thought you could use these for the antique of the day feature in theCantina. Knock yourself out with these. I got more if you need them,just please give me credit for the shots.

Thanks and enjoy,

Teddy Bear

BIKE SHOW WINNERS FOR APRIL–Sorry about that. I just got back from the Keys. I forgot to e-mail you withthe list before I left. The Keys trip was insane. It’s the only word todescribe it. I just need to check myself into the looney bin and get it overwith. I still can’t believe it. Like something out of a movie. And I thoughtthis past winter’s adventures were too much. Not even close.

Here’s the list and picture.-JoAnn

In The “Competition” Category

Ray Devine

ST. LOUIS, Mo.

In The “Pro-Street” Category

Thad Cranford

Zachary, La.

In The “Radical Custom” Category

Clay Huckins

Lake Havasu City, Ariz.

In The “Ridden” Category

Jay McGuire

Indio, Calif.

In The “Sportster” Category

Shelly Robertson

Iowa Park, Texas

In The “Street Custom-Stock” Category

Jim Spaciel

Milwaukee, Wis.

In The “Vintage” Category

Teddy Bear Babolcsay

Elizaville, N.Y.

Each Winner received a signed book from Bandit, a T-shirt from JIMS Machine or Crime Inc., or a Crime Inc. wallet or a gift certificate from Samson Exhaust. Of course each winner also recieved one famous Bikernet Bike Show trophy.

HEY NOW–Check out the first-ever Blue Cafe Blues Festival info.!!!1st. Annual Blue Cafe Blues FestivalThe Fabulous Thunderbirdsheadline!!!

The Green on the Hill27th & Walnut, Signal Hill Ca.Sunday June 17th. FATHER’S DAY!!!sorry, forgot the date… and i’m a father!Don’t tell my son…

–vj

A TEXAN–a Californian, and an Oregonian are out riding horses. The Texan pulls out an expensive bottle of whiskey, takes a long draught, then another and suddenly throws it into the air, pulls out his gun and shoots the bottle in midair.

The Californian looks at him and says, “What are you doing? That was a perfectly good bottle of whiskey!”

The Texan says, “In Texas, there is plenty of whiskey and the bottles are cheap.”