Latest Articles

WIN BY HARLEY-DAVIDSON RACERS JAKE LEWIS & CORY WEST

HARLEY-DAVIDSON® PAN AMERICA® ST RACERS JAKE LEWIS AND CORY WEST WIN IN MISSION SUPER HOOLIGAN ...

1939 Harley-Davidson Knucklehead is headed to someone’s garage

ONLY TWO DAYS LEFT CLICK TO WIN https://store.wheelsthroughtime.com/win-this-bike The 2025 WTT Raffle Grand Prize is ...

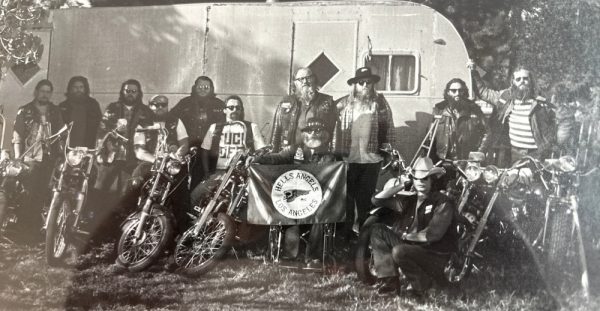

CLUB FIGHTS 1976

I just watched the George Clooney and Evan McGregor film, “Men who Stare at Goats.” ...

National Council of Informed Riders

National Council of Informed Riders (National COIR) KEEPING YOU INFORMED National COIR has joined 5 ...

New in the Cantina

Weekly News

HALLOWEEN BIKERNET WEEKLY NEWS for October 28, 2021

Hey,On Halloween the Glasgow Climate Conference will kick off with Mother Nature disguised as an ...

THE NUTS BIKERNET WEEKLY NEWS for October 21, 2021

Hey, Weekly I ask myself if I’m nuts and on the wrong track. I know ...

FOSSIL FUEL BIKERNET WEEKLY NEWS for October 14th, 2021

Hey,Interesting day in Paradise. I watched another movie by Ben Affleck and of course his ...

GETTING A GRIP BIKERNET WEEKLY NEWS for October 7, 2021

Hey,What do you think? We’re headed directly into the magnificent Holidays. Sometimes I get depressed ...

Tech Articles

A Better Cheaper Brake

This tech was blessed by the Bikernet.com and Sturgis Ride Live.com girls.One night while browsing ...

Fueling Super Scavenger Oil Pump for Twin Power

Ok, ok, ok….so you want me to check out a new oil pump by Fueling, ...

Oil Line Tech

This oilpump photograph shows the vent line behind the oil pump. This is aShovelhead with ...

Bike Features

Angry White Roy’s Shovelhead

We have a 1984 Shovelhead in the shop and have been unhappy with the primary ...

FUNKENSTEIN LIVES!

Duane Ballard is no stranger to the custom bike scene.Having made custom hand tooled seats ...

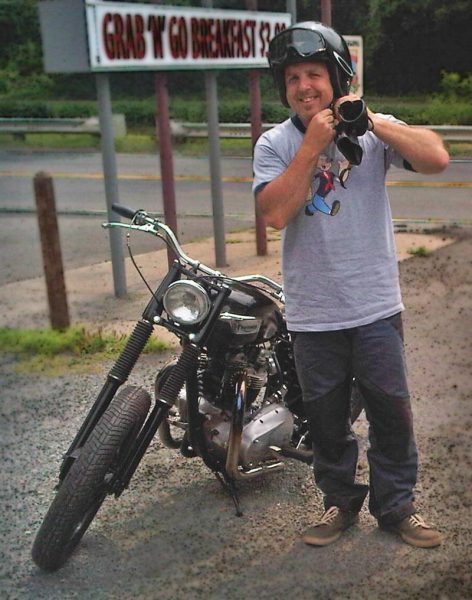

Nimi’s Bonnie Is Alright

You really meet the nicest people when you start hanging around motorcycle forums. There’s always ...

Event Features

WIN BY HARLEY-DAVIDSON RACERS JAKE LEWIS & CORY WEST

HARLEY-DAVIDSON® PAN AMERICA® ST RACERS JAKE LEWIS AND CORY WEST WIN IN MISSION SUPER HOOLIGAN ...

Roads to Redbud 2025

Hey all - anyone venturing to Buchanan Michigan on the 5th of July, for the ...

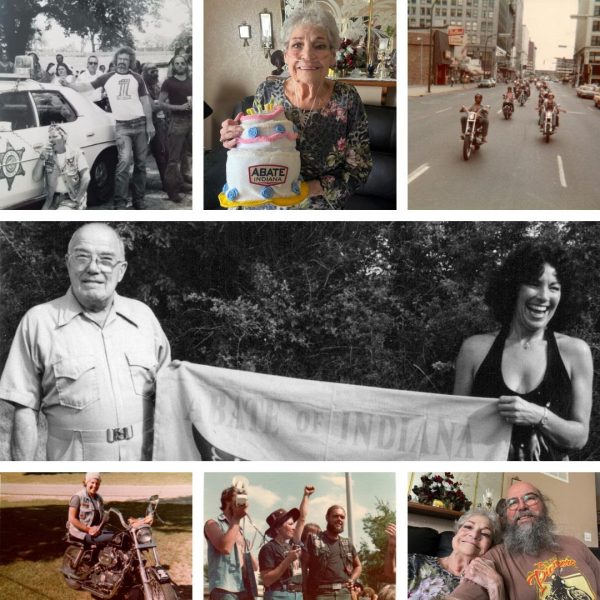

Happy Birthday ABATE Of Indiana

In the mid-seventies, the motorcycle rights movement really started in earnest. This is why many ...

AMA Motorcycle Hall of Fame Announces Class of 2025

Six distinguished motorcyclists to be inducted on Oct. 23 during the AMA Hall of Fame ...