Latest Articles

Thoughts for the Weekend

Some motivation and some inspiration. Here are some quotes to ponder. Get on your steed ...

UNINTENTIONAL PILGRIMAGE 2025

This is the third year of this event which started off to simply honor those ...

Long Road 2025 registrations are due

Long Road 2025 registrations are due August 11, include your shirts size (M or F). ...

Celebrating America’s Birthday

July 4th, 2025 Each fourth of July we celebrate the birth of American Independence. We ...

New in the Cantina

Weekly News

THE STURGIS RALLY 2022 BIKERNET WEEKLY NEWS for August 4th, 2022

Hey,If you’re rolling into the majestic black hills for the rally, feel free to drop ...

HIGH PRESSURE BIKERNET WEEKLY NEWS for July 28, 2022

Hey,It seems like the pressure is on. The rally is just around the corner and ...

The TRUTH BIKERNET WEEKLY NEWS for July 21st, 2022

Hey,The truth is everything. I scrambled out of bed a 6:24 this morning. My mission, ...

RALLY PLANNING BIKERNET WEEKLY NEWS for July 14th, 2022

Hey,My grandson just experienced his first rally vendor effort in Southern California. He’s 28 and ...

Tech Articles

Rocking K Custom Leather – The Bikernet / Cycle Source Anniversary Chopper Leather Solution

The Bikernet/Cycle Source Sweeps saw its grand finale in Las Vegas and a Cycle Source ...

Part III, H-D Evo Remanufacturing Process Continues

This chapter covers the final elements of installing the cam case gears, the top end, ...

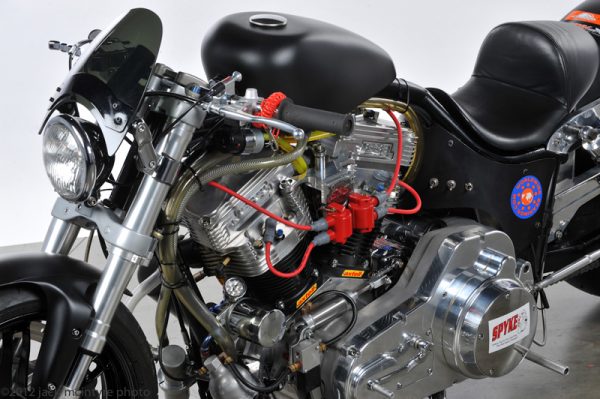

G2 Gangster-Street Legal Street Pro Bike

This is an interesting one. We met Paul Morris at the Long Beach Ultimate Builder ...

Big Boar Dyna 240mm Fat Tire Kit

Here's a rare shot of the house where the Devil was born in Transylvania. Today ...

Bike Features

Buy it for a Nickel(Plated)

Yep, it’s a trick question in a couple of ways. But yes, nickel plays a ...

The Glasster Panhead

This wild chunk of functional motorcycle art was recently featured in Hot Bike Magazine. How ...

THE McQuiston K

Ryan McQuiston is living the biker dream. He rides, wrenches, snorts 20/50-weight, and does it ...

The Candy Green Machine

I often feel like a basketball player during the final game of the season, when ...

Event Features

UNINTENTIONAL PILGRIMAGE 2025

This is the third year of this event which started off to simply honor those ...

Long Road 2025 registrations are due

Long Road 2025 registrations are due August 11, include your shirts size (M or F). ...

WIN BY HARLEY-DAVIDSON RACERS JAKE LEWIS & CORY WEST

HARLEY-DAVIDSON® PAN AMERICA® ST RACERS JAKE LEWIS AND CORY WEST WIN IN MISSION SUPER HOOLIGAN ...

Roads to Redbud 2025

Hey all - anyone venturing to Buchanan Michigan on the 5th of July, for the ...