Latest Articles

WIN BY HARLEY-DAVIDSON RACERS JAKE LEWIS & CORY WEST

HARLEY-DAVIDSON® PAN AMERICA® ST RACERS JAKE LEWIS AND CORY WEST WIN IN MISSION SUPER HOOLIGAN ...

1939 Harley-Davidson Knucklehead is headed to someone’s garage

ONLY TWO DAYS LEFT CLICK TO WIN https://store.wheelsthroughtime.com/win-this-bike The 2025 WTT Raffle Grand Prize is ...

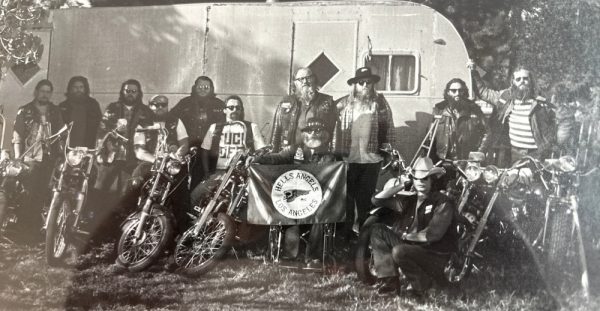

CLUB FIGHTS 1976

I just watched the George Clooney and Evan McGregor film, “Men who Stare at Goats.” ...

National Council of Informed Riders

National Council of Informed Riders (National COIR) KEEPING YOU INFORMED National COIR has joined 5 ...

New in the Cantina

Weekly News

COOL BIKERNET WEEKLY NEWS for August 25th 2022

Hey, The Rally is a couple of weeks behind us, and hopefully I will launch my ...

POST RALLY BLUES BIKERNET WEEKLY NEWS for August 18th, 2022

Hey,The rally came and went in the blink of an eye. I’m trying to write ...

RALLY WINDING DOWN BIKERNET WEEKLY NEWS for August 11th, 2022

Hey,Thursday will be nuts. Not sure if the news will be finished on Thursday or ...

THE STURGIS RALLY 2022 BIKERNET WEEKLY NEWS for August 4th, 2022

Hey,If you’re rolling into the majestic black hills for the rally, feel free to drop ...

Tech Articles

Bikernet/Cycle Source Sweeps Build Part 5 Sponsored by Xpress

Don't miss the last episode: http://www.bikernet.com/pages/BikernetCycle_Source_Sweeps_Build_Part_4.aspx I’ve never had so much fun building a bike, and it’s ...

Monster Twin Cam Race Engines from JIMS

This is a short and super-sweet announcement. Not only did JIMS develop an American Made, ...

The History of the Talon Kickstand

10TH ANNIVERSARY KICKSTAND STORY--How on Earth would anyone come up with the idea to create ...

Part 4: Cabana Dan’s Early Projects

It’s Memorial Day 2023. There’s a jammin’ bike show happening in Deadwood. Dan’s hands are ...

Bike Features

Michael Shumacher Meets Garage Co.

Seven time world champion Formula One racer Michael Schumacher expresses his reaction to surprise present ...

Lake Elsinore Knucklehead

Here’s a fine looking Knucklehead from an old school builder who dumped his ol’ lady ...

The Black Hills Beast

Basedon a new 2015 Indian Scout and customized to emulate thepurpose-built nature of historic hill ...

The Mystery Manx Cookery

Editor’s Note: This is a mystery sled. As you will see it has function, heritage ...

Event Features

WIN BY HARLEY-DAVIDSON RACERS JAKE LEWIS & CORY WEST

HARLEY-DAVIDSON® PAN AMERICA® ST RACERS JAKE LEWIS AND CORY WEST WIN IN MISSION SUPER HOOLIGAN ...

Roads to Redbud 2025

Hey all - anyone venturing to Buchanan Michigan on the 5th of July, for the ...

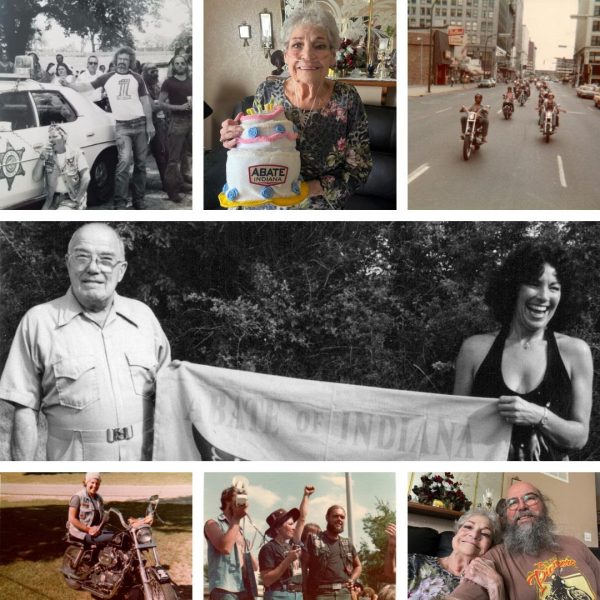

Happy Birthday ABATE Of Indiana

In the mid-seventies, the motorcycle rights movement really started in earnest. This is why many ...

AMA Motorcycle Hall of Fame Announces Class of 2025

Six distinguished motorcyclists to be inducted on Oct. 23 during the AMA Hall of Fame ...