Latest Articles

Select 2025 Harley-Davidson motorcycles available worldwide

HARLEY-DAVIDSON REVEALS SELECT 2025 MOTORCYCLES NOW AVAILABLE AT WORLDWIDE AUTHORIZED DEALERSHIPSAdditional New Harley-Davidson Motorcycles to ...

Who will grab KTM eventually?

Will KTM become a Chinese funded brand?Three primary investors show interest in KTMMaybe keeping KTM ...

THE WILD NEW YEARS DAY BIKERNET WEEKLY NEWS for January 1st, 2025

Holy Shit, I remember 2000 like it was yesterday. What the hell happened to 25 ...

THE BOARD MEETING

Bandit Steps Up Strange times and Bandit scratched his head as he dealt with issues ...

New in the Cantina

Weekly News

IT’S A WONDERFUL PLACE BIKERNET WEEKLY NEWS for June 30, 2022

Hey,This could be a magnificent day in the hood. As you will see in the ...

THE CONUNDRUM BIKERNET WEEKLY NEWS for June 23, 2022

I’m in a conundrum, which means a mystery, a challenge or a questioning problem. I’ve ...

THE BROTHERHOOD BIKERNET WEEKLY NEWS for June 16th, 2022

Hey, Life for a biker is a wonderful thing, primarily because of the brotherhood. Whether ...

INTEGRITY BIKERNET WEEKLY NEWS for June 9th, 2022

Hey,This is a tough one and I don’t get it, but maybe I do. I ...

Tech Articles

It’s Hot Between My Legs

That Can Be Fixed Sitting at the kitchen table with Rogue, enjoying reading Facebook posts ...

JIMS TOOL OF THE WEEK 10-3-24

JIMS Primary Locking Bar for Milwaukee-Eight Softail Models In 2018, Harley-Davidson launched the Milwaukee-Eight Softail ...

Bike Features

NEW PANHEAD ROLLS INTO THE EMPORIUM

Charlie’s ’51 EL Charlie’s a wild man with a long flapping gray beard. At 65 ...

5th Place European Championship 2006

Fifth place was taken by Krazy Horse Cycles from the UK, with their ‘Zeroesque’, an ...

Aussie Shovelhead Tribute

A long time self-confessed bike nut, Glenn remembers riding back in the day when dodging ...

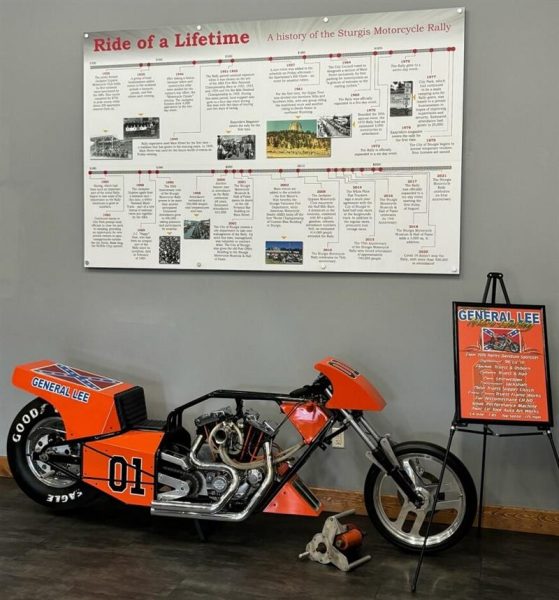

TRUETT & OSBORN DOUBLES

Editor’s Note: The Sturgis Museum and Hall of Fame curation committee recently received the opportunity ...

Event Features

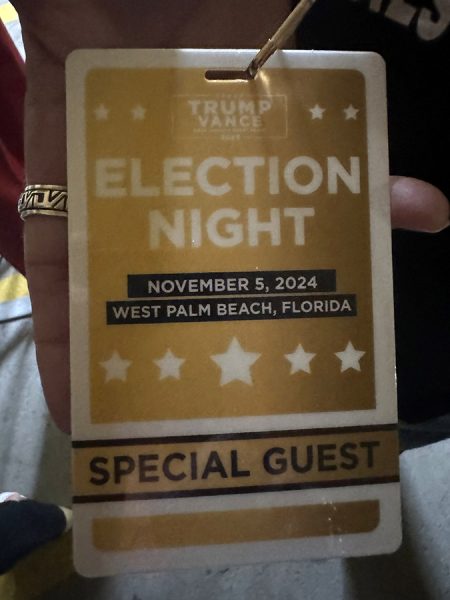

PRESIDENT TRUMP ELECTION NIGHT WATCH PARTY

WEST PALM BEACH CONVENTION CENTER TUESDAY,NOVEMBER 5 THRU WEDNESDAY,NOVEMBER, 6,2024 PROMISES MADE, PROMISES KEPT ...

Tropical Tattoo’s Choppertime

Biketoberfest 2024 Story and photos by Katmandu This October, your motorcycle mecca, also known as ...

LC Fabrications’ Jeremy Cupp takes Freestyle in Washington, DC

Jeremy Cupp took 2nd in New York before the holiday break and then motored into ...

Arizona HOG Rally 2012 Rocks Williams, Arizona

The annual Arizona HOG Rally recently returned to the historic mountain settlement of Williams. The ...